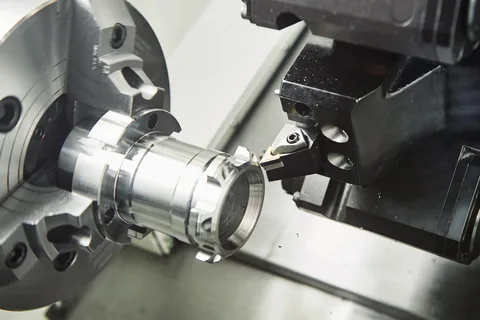

How to Find the Best Online CNC Turning Service for Custom Projects

Finding a reliable online CNC turning service can be the key to executing custom projects with precision, efficiency, and cost-effectiveness. CNC (Computer Numerical Control) turning allows for the creation of highly detailed components from various materials, including metals, plastics, and composites. With the growing demand for custom parts across industries like automotive, aerospace, and manufacturing, knowing how to choose the right service provider is critical. This guide will walk you through the factors to consider, features to look for, and strategies to ensure your custom project meets the highest standards.

Understanding Your Project Requirements

Before you begin searching for an online CNC turning service, it’s crucial to clearly define your project’s requirements. Consider the dimensions, tolerances, materials, and complexity of the parts you need. Some CNC services specialize in high-precision metal components, while others may be better suited for plastics or composite materials. The more detailed your specifications, the easier it will be to find a provider who can meet your exact needs.

Knowing the end-use of your component also matters. For instance, a part used in aerospace applications may require tighter tolerances and certification compliance compared to a prototype for consumer electronics. Documenting these requirements will serve as a checklist when evaluating potential service providers, ensuring you don’t compromise on quality or capabilities.

Researching and Comparing Service Providers

The next step is to research and compare different online CNC turning services. Start by reviewing the company’s website to understand the range of services, materials, and machinery they offer. A reputable provider will often provide case studies, sample projects, or client testimonials that showcase their expertise. You can also explore online forums, review platforms, and professional networks to gain insights from previous customers.

Comparing multiple providers helps you identify which services align with your project requirements and budget. Pay attention to factors such as lead times, pricing structure, minimum order quantities, and whether they offer rapid prototyping or production runs. Choosing a provider who balances quality, reliability, and affordability is essential for long-term project success.

Evaluating Technical Capabilities and Equipment

A key factor in selecting an online CNC turning service is evaluating their technical capabilities and machinery. Modern CNC turning requires advanced equipment, such as multi-axis lathes, high-speed spindles, and precision measurement tools, to produce accurate and consistent parts. A provider with state-of-the-art machinery can handle complex geometries, tight tolerances, and various materials efficiently.

Additionally, consider the provider’s expertise in CAD/CAM software, as this directly affects the quality of the finished product. A competent team should be able to interpret your design files accurately and offer suggestions to improve manufacturability without compromising functionality. Ensuring that the service has both advanced machinery and skilled operators is crucial for achieving the results you need.

Assessing Quality Control and Certifications

Quality control is a non-negotiable aspect of any online CNC turning service. Reputable providers implement rigorous inspection processes to ensure that every component meets the specified standards. This includes dimensional inspections, surface finish evaluations, and material property testing. Some services also provide detailed inspection reports or certificates of compliance for each batch, which is especially important for industries with strict regulatory requirements.

Certifications, such as ISO 9001 or AS9100, indicate that the service adheres to international quality management standards. These certifications demonstrate a commitment to consistency, reliability, and traceability. When evaluating potential CNC turning partners, prioritize those who maintain robust quality control protocols and industry-recognized certifications, as this minimizes the risk of defects or project delays.

Understanding Customer Support and Communication

Finally, customer support and communication are essential when working with an online CNC turning service. Even the most technically advanced provider can fall short if they do not communicate effectively throughout the project. Look for services that offer direct contact with engineers or project managers who can address questions, provide updates, and suggest improvements during the production process.

Timely communication also plays a role in problem-solving and managing expectations. Whether it’s clarifying design specifications, adjusting production schedules, or handling shipping concerns, a responsive support team ensures your project runs smoothly from start to finish. Choosing a provider that prioritizes clear, proactive communication can save time, reduce errors, and enhance the overall project experience.

Conclusion

Selecting the best online CNC turning service for custom projects requires careful planning, research, and evaluation. By understanding your project requirements, comparing providers, assessing technical capabilities, prioritizing quality control, and valuing effective communication, you can find a service that delivers high-quality, precise components on time and within budget. With the right partner, your custom CNC projects can achieve exceptional results, whether for prototyping, small-scale production, or complex industrial applications.