How Light Construction Equipment by Topall Impex Boosts Safety, Speed, and Savings in Modern Projects

Introduction

Construction projects today demand greater efficiency, safety, and durability. From residential developments to large infrastructure, the right machines can make all the difference. Contractors increasingly rely on Light Construction Equipment to ensure timely project completion without compromising quality or cost. Compact yet powerful, this machinery bridges the gap between manual labor and heavy machines, offering enhanced productivity at reduced operational expenses.

Topall Impex, a trusted name in India, has become a leading supplier and manufacturer of advanced equipment. Its wide range of machines is designed to improve performance in core construction activities such as bending, cutting, compacting, and threading reinforcement bars, as well as soil preparation and road construction. By investing in these modern solutions, contractors can achieve safety, speed, and savings on every project.

Why Light Construction Equipment Matters

The construction industry has shifted to faster, smarter practices. Heavy machinery is useful but not always practical for compact worksites or specialized tasks. Light equipment is cost-effective, mobile, and easy to operate, making it an essential part of modern projects.

These machines help:

-

Save time by automating labor-intensive tasks.

-

Improve safety with advanced operator protection.

-

Reduce costs through efficient performance and lower maintenance needs.

-

Enhance accuracy by delivering consistent results.

Topall Impex designs its equipment to align with these needs, ensuring that every project runs smoothly and efficiently.

Key Equipment by Topall Impex

Bar Bending Machine – Accuracy in Reinforcement Work

Reinforcement bars form the backbone of concrete structures, and bending them with precision is vital. The Bar Bending Machine from Topall Impex ensures bars are bent accurately to meet engineering requirements, avoiding structural weaknesses and costly rework. By automating this process, contractors save significant labor hours while maintaining high safety standards.

Bar Cutting Machine – Speed with Safety

Cutting steel manually is not only time-consuming but also unsafe. The Bar Cutting Machine provides quick, accurate, and safe cuts. This machine handles different bar sizes effortlessly, ensuring reduced wastage and faster reinforcement preparation. Its safety features protect workers while its efficiency helps projects stay on schedule.

Bar Straightening Machine – Improving Efficiency

Rebars are often delivered in coiled or uneven shapes, making them unsuitable for direct use. The Bar Straightening Machine solves this issue by straightening bars uniformly, improving their usability and precision in construction. This reduces waste, saves costs, and guarantees that reinforcement bars fit perfectly into the project’s design requirements.

Mini Road Roller – Compact Power for Roads

For smaller road projects, pathways, or compact sites, large rollers are impractical. The Mini Road Roller is an efficient alternative that delivers excellent compaction. Its compact design makes it highly maneuverable, saving fuel and operational costs while ensuring strong and long-lasting road surfaces.

Tamping Rammer – Effective Soil Compaction

Before laying foundations or pavements, soil preparation is essential. The Tamping Rammer provides high-impact compaction, even in narrow spaces where bigger machines cannot work effectively. This ensures stable ground, reducing the risk of structural settlement and future maintenance costs. Contractors benefit from faster preparation and improved long-term stability.

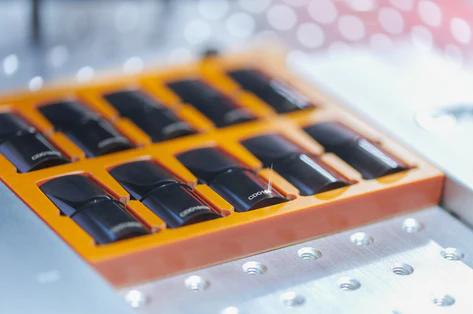

Bar Threading Machine – Reliable Reinforcement Joints

Creating strong joints between rebars is crucial for building durability. The Bar Threading Machine delivers precise threads that ensure secure, uniform connections. This not only speeds up reinforcement assembly but also guarantees safety, minimizing the chances of structural failure.

Case Scenarios

-

Residential Project: By using Bar Bending and Cutting Machines, contractors reduced rebar preparation time by nearly 35%, ensuring deadlines were met without compromising quality.

-

Urban Roads: Mini Road Rollers and Tamping Rammers allowed compaction in congested city lanes, reducing fuel usage and lowering project costs by 20%.

-

High-Rise Towers: Bar Straightening and Threading Machines simplified reinforcement placement, enhancing structural safety while eliminating rework.

Why Contractors Choose Topall Impex

-

Durability: Machines built with high-grade materials for long-term reliability.

-

Performance: Designed to deliver consistent results under demanding conditions.

-

Safety: Integrated protective features for operator security.

-

Affordability: Cost-effective solutions that balance quality with budget needs.

-

Support: Nationwide supply and after-sales service ensure smooth operations.

These advantages make Topall Impex the preferred choice for contractors aiming to maximize project efficiency.

Conclusion

Efficiency, safety, and cost-effectiveness define success in modern construction. By using specialized machines like Bar Bending, Bar Cutting, Bar Straightening, Mini Road Roller, Tamping Rammer, and Bar Threading Machines, contractors can streamline workflows while ensuring durability and worker safety.

Topall Impex, with its advanced Light Construction Equipment, continues to empower the industry with machinery that transforms challenges into opportunities. For professionals seeking reliable, durable, and high-performance equipment, Topall Impex remains the name to trust.