Rigid Box: The Ultimate Packaging for Premium Products

Packaging does more than protect a product; it defines how a brand is perceived. A rigid box is one of the most luxurious and protective forms of packaging available today. Used across industries from electronics to cosmetics, a rigid boxes offers unmatched strength, elegance, and customizability. In this guide, you’ll learn everything about rigid box packaging—from its structure and advantages to applications, styles, and manufacturing.

16 Wishes Candles rigid box

The 16 Wishes Candle boxes offers a luxurious, durable packaging solution that enhances both protection and presentation. These elegantly crafted 16 Wishes Candle Boxes are perfect for gifting, with custom designs that reflect the brand’s charm and quality, ensuring a memorable unboxing experience for every candle lover.

What is a Rigid Box?

A rigid box (also called a set-up box) is a non-collapsible packaging solution made from high-thickness paperboard or chipboard. Unlike folding cartons, a rigid box retains its shape and is designed for strength and premium presentation.

The board used in a rigid box typically ranges from 800gsm to 1400gsm, giving it a firm structure. It's wrapped in printed or textured paper for branding and aesthetic value.

Key Features of a Rigid Box

A rigid box offers several features that distinguish it from other types of packaging:

-

Stiff Structure: Thick chipboard maintains form.

-

Custom Wrapping: Surface wrapped in premium paper or fabric.

-

High-End Finishes: Includes embossing, foiling, or UV coating.

-

Non-Foldable: Pre-assembled and ready to use.

-

Reusable: Often repurposed by consumers.

These attributes make a rigid box a go-to solution for luxury branding.

Types of Rigid Boxes

Different product needs require different box styles. Popular rigid box styles include:

1. Two-Piece Rigid Box (Lid and Base)

Classic and simple, it consists of a base and a separate lid. Common in smartphone and clothing packaging.

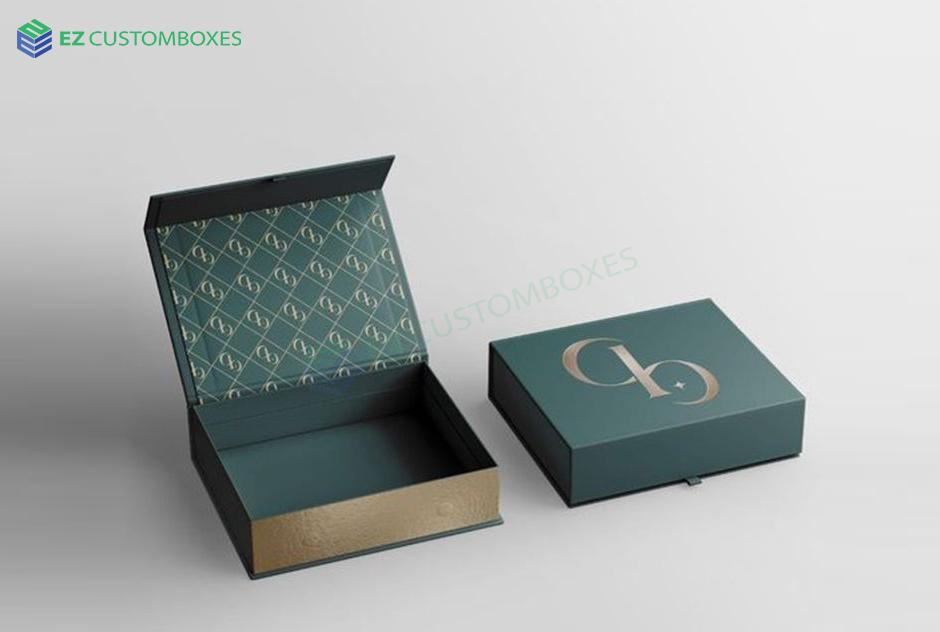

2. Magnetic Closure Rigid Box

Features built-in magnets in the flap, providing a sleek and secure closure. Frequently used in high-end electronics and cosmetics.

3. Drawer Style Rigid Box

Also called a matchbox design, this features a sliding tray inside a sleeve. Adds a modern and interactive unboxing experience.

4. Book Style Rigid Box

Opens like a book, often with magnetic or ribbon closures. Ideal for gift sets and premium items.

5. Shoulder and Neck Rigid Box

This style involves a third component (the neck), giving a high-end, layered appearance.

Each rigid box style can be fully customized to suit specific product requirements and branding aesthetics.

Manufacturing Process

The process of making a rigid box combines precision machinery and manual craftsmanship:

-

Board Cutting: Chipboard is die-cut into precise dimensions.

-

Box Assembly: Corners are glued and reinforced.

-

Wrapping: A printed or textured paper is glued onto the board.

-

Finishing: Embellishments like foil stamping, magnetic closures, and ribbons are added.

Because of its complexity, a rigid box usually takes longer to produce than folding cartons, but the result is worth it.

Materials Used in Rigid Boxes

A rigid box typically uses the following materials:

-

Greyboard or Chipboard: For the inner structure.

-

Art Paper or Specialty Paper: For outer wrapping.

-

Inserts: Foam, EVA, or cardboard inserts for product protection.

-

Magnets, Ribbons, or Fabric: For closures and added value.

High-quality materials ensure that a rigid box is not only strong but also visually impressive.

Advantages of Using a Rigid Box

1. Luxurious Appearance

A rigid box adds a sense of value and exclusivity, which elevates the brand and justifies premium pricing.

2. Exceptional Durability

The thick board protects against crushing, moisture, and impact—perfect for fragile or expensive items.

3. Unlimited Customization

Every aspect of a rigid box, from its shape to finishing, can be customized.

4. Improved Customer Experience

Opening a well-designed rigid box enhances the unboxing experience, boosting brand perception and customer satisfaction.

5. Reusability

Many customers reuse their rigid box for storage, giving your brand long-term visibility.

Rigid Box vs Folding Carton

| Feature | Rigid Box | Folding Carton |

|---|---|---|

| Structure | Non-collapsible | Foldable |

| Material Thickness | 800–1400 gsm | 250–450 gsm |

| Durability | High | Moderate |

| Presentation | Premium | Standard |

| Cost | Higher | Lower |

| Use Case | Luxury, fragile goods | Mass-market products |

The rigid box is clearly the superior choice when presentation and protection are key.

Common Industries Using Rigid Boxes

1. Electronics

Smartphones, headphones, and smartwatches are often packaged in a rigid box for superior protection and premium branding.

2. Cosmetics and Perfume

Brands use rigid box packaging to reflect elegance and value, especially for perfumes and skincare sets.

3. Jewelry

For rings, necklaces, and watches, a rigid box enhances both safety and aesthetic appeal.

4. Luxury Fashion

Apparel, belts, and accessories from premium brands often arrive in custom rigid box designs.

5. Food and Beverage

Gourmet chocolates, wines, and teas frequently use rigid box packaging for gifting and presentation.

Customization Options

A rigid box can be fully personalized through:

-

Size and Shape: Tailored to product dimensions.

-

Color Schemes: Brand-specific palettes.

-

Logos and Text: Printed, embossed, or foil stamped.

-

Textures and Materials: Linen, leatherette, or soft-touch lamination.

-

Inserts: Molded foam, silk lining, or cardboard dividers.

With so many options, a rigid box becomes an extension of your brand identity.

Sustainability of Rigid Boxes

As sustainability becomes critical, the rigid box industry has evolved:

-

Eco-Friendly Boards: FSC-certified and recycled materials are common.

-

Recyclable Wrapping: Soy-based inks and water-based coatings.

-

Reusable Designs: Many rigid box structures are kept and reused by consumers.

Choosing sustainable rigid box solutions reflects positively on your brand and appeals to eco-conscious buyers.

Cost Considerations

A rigid box is more expensive than basic packaging, but it delivers higher value. Pricing factors include:

-

Material Thickness

-

Box Style and Size

-

Custom Finishes

-

Quantity Ordered

-

Manual Labor Involved

Brands investing in rigid box packaging often see better customer retention and increased perceived value, making it cost-effective in the long run.

Choosing a Rigid Box Supplier

When selecting a packaging partner, ensure they offer:

-

Design Consultation

-

Low Minimum Order Quantities

-

High Print Quality

-

Sustainable Options

-

Efficient Turnaround Time

A reliable supplier ensures that your rigid box matches brand expectations in quality and delivery.

Trends in Rigid Box Packaging

The rigid box market is rapidly evolving. Current trends include:

-

Minimalist Design: Clean layouts with subtle textures.

-

Eco-Packaging: Recyclable and compostable materials.

-

Smart Packaging: QR codes, NFC tags for interactive engagement.

-

Personalization: Names and messages printed directly on the box.

Staying ahead of trends keeps your rigid box packaging fresh and competitive.

How Many Cigarettes in a Pack rigid box

The How Many Cigarettes in a Pack, premium solution for tobacco packaging. Typically answering the question, How Many Cigarettes in a Pack, the standard count is 20. This rigid box design enhances protection, preserves freshness, and adds a touch of sophistication to traditional cigarette packaging.

Conclusion

A rigid packaging it’s a branding tool, a protective shell, and a customer experience enhancer. With its luxurious finish, durability, and design flexibility, the rigid box remains the top choice for premium brands across industries.

Investing in custom rigid box packaging shows your commitment to quality and elevates your product's perceived value. Whether you're selling electronics, jewelry, or cosmetics, a well-crafted rigid box can be the difference between ordinary and unforgettable.