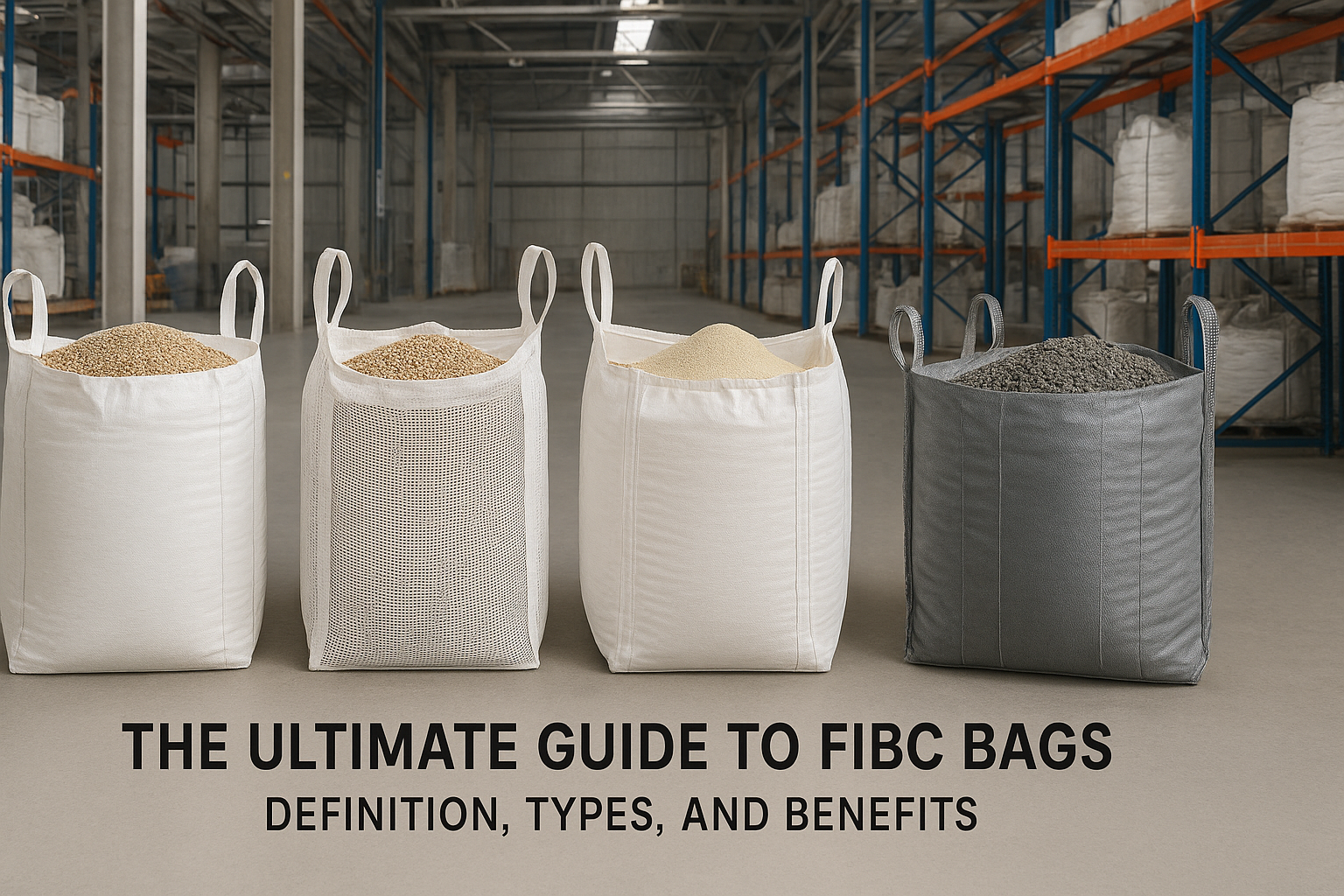

The Ultimate Guide to FIBC Bags: Definition, Types, and Benefits

When it comes to handling and transporting large quantities of dry, flowable goods, FIBC bags (Flexible Intermediate Bulk Containers) have become the go-to solution across multiple industries. Whether you’re in agriculture, chemicals, construction, or food processing, these durable bulk packaging bags provide efficiency, safety, and cost-effectiveness.

But what exactly are FIBC bags? What are the different types of FIBC bags, and why should you consider them for your business? This guide will break it all down in simple terms.

What Is an FIBC Bag?

An FIBC bag, often referred to as a bulk bag or jumbo bag, is a large, flexible container made from woven polypropylene fabric. They are designed to store and transport bulk quantities of dry materials such as grains, powders, minerals, and even construction debris.

Most FIBC bags can carry loads ranging from 500 kg to 2000 kg, depending on their design and construction. Their strength, stackability, and reusability make them an ideal choice for industries that need reliable packaging for heavy materials.

The Different Types of FIBC Bags

Not all bulk bags are the same. Each type is designed with specific features to handle unique materials and conditions. Here’s a quick overview of the most common types of FIBC bags:

1. U-Panel FIBC Bags

These bags are constructed with three main panels (two sides and a U-shaped body). They are cost-effective, durable, and maintain a square shape when filled. U-panel bags are widely used for products like grains, seeds, and fertilizers.

2. Circular (Tubular) FIBC Bags

Made from a single piece of tubular fabric, circular bags eliminate side seams, which makes them strong and less prone to leakage. They are popular for fine powders or materials that need extra protection from spillage.

3. Baffle FIBC Bags

Baffle bags are equipped with internal panels that help the bag maintain a cubical shape. This design maximizes storage space and makes stacking easier during storage or transportation. These are particularly useful for shipping and warehousing.

4. Single-Loop & Two-Loop FIBC Bags

These bags feature fewer lifting loops, making them more economical. They are ideal for industries where bags are handled by forklifts or cranes.

5. Four-Loop FIBC Bags

The most common type, four-loop bags are versatile and used across multiple sectors. They allow easy lifting and transport, even with heavy loads.

6. UN-Certified FIBC Bags

For hazardous materials such as chemicals or minerals, UN-certified bags are mandatory. These bags meet international safety standards for transporting dangerous goods.

7. Coated and Uncoated FIBC Bags

Coated bags have an extra polypropylene layer to prevent moisture and dust ingress, while uncoated bags are breathable, making them suitable for products like potatoes or onions.

Key Benefits of Using FIBC Bags

Adopting FIBC bags offers businesses several advantages, including:

1. Cost Efficiency

Compared to traditional packaging methods like drums or small sacks, bulk bags reduce packaging costs significantly. Their large capacity minimizes labor and handling time.

2. Safety and Durability

FIBC bags are built to handle heavy loads safely. With proper lifting loops and sturdy fabric, they reduce the risk of product loss or accidents during handling.

3. Space Optimization

With baffle bags and stackable designs, storage becomes more organized and efficient, reducing warehouse costs.

4. Versatility Across Industries

From food-grade bags to specialized chemical-resistant designs, FIBC bags can be customized to suit virtually any industry requirement.

5. Sustainability

Polypropylene bulk bags are reusable and recyclable, making them a sustainable packaging choice compared to disposable alternatives.

Choosing the Right FIBC Bulk Bag Manufacturers

Not all suppliers are the same. The best FIBC bulk bag manufacturers go beyond selling bags - they act as partners who understand your industry challenges. A reliable manufacturer offers:

- Consistent product quality backed by testing and certifications

- Options to customize bag size, strength, and design

- Clear communication and on-time delivery

- Guidance on choosing the right bag for your material and application

This ensures your bulk packaging solution adds value rather than causing operational hiccups.

Why FIBC Bags Are a Smarter Choice Today

From agriculture to construction, businesses are shifting to bulk bags because they reduce costs, streamline handling, and minimize material loss. With multiple types of FIBC bags available - from U-panel to baffle and UN-certified - it’s easier than ever to match packaging to your exact product requirements. The result? Better efficiency, safer storage, and higher profitability.

Looking for reliable bulk packaging solutions?

Contact us today to explore a wide range of FIBC bags designed to match your industry needs.