Why ESD Safety And Monitoring Are Important In Today's Workplaces

Businesses use ESD monitors, ESD assessments, and full static control monitoring systems to make sure safety, quality, and compliance. In addition to these, tools like portable fume extractors, airborne particle counter, ionisers, and lithium battery boxes are very important for keeping the area safe and under control.

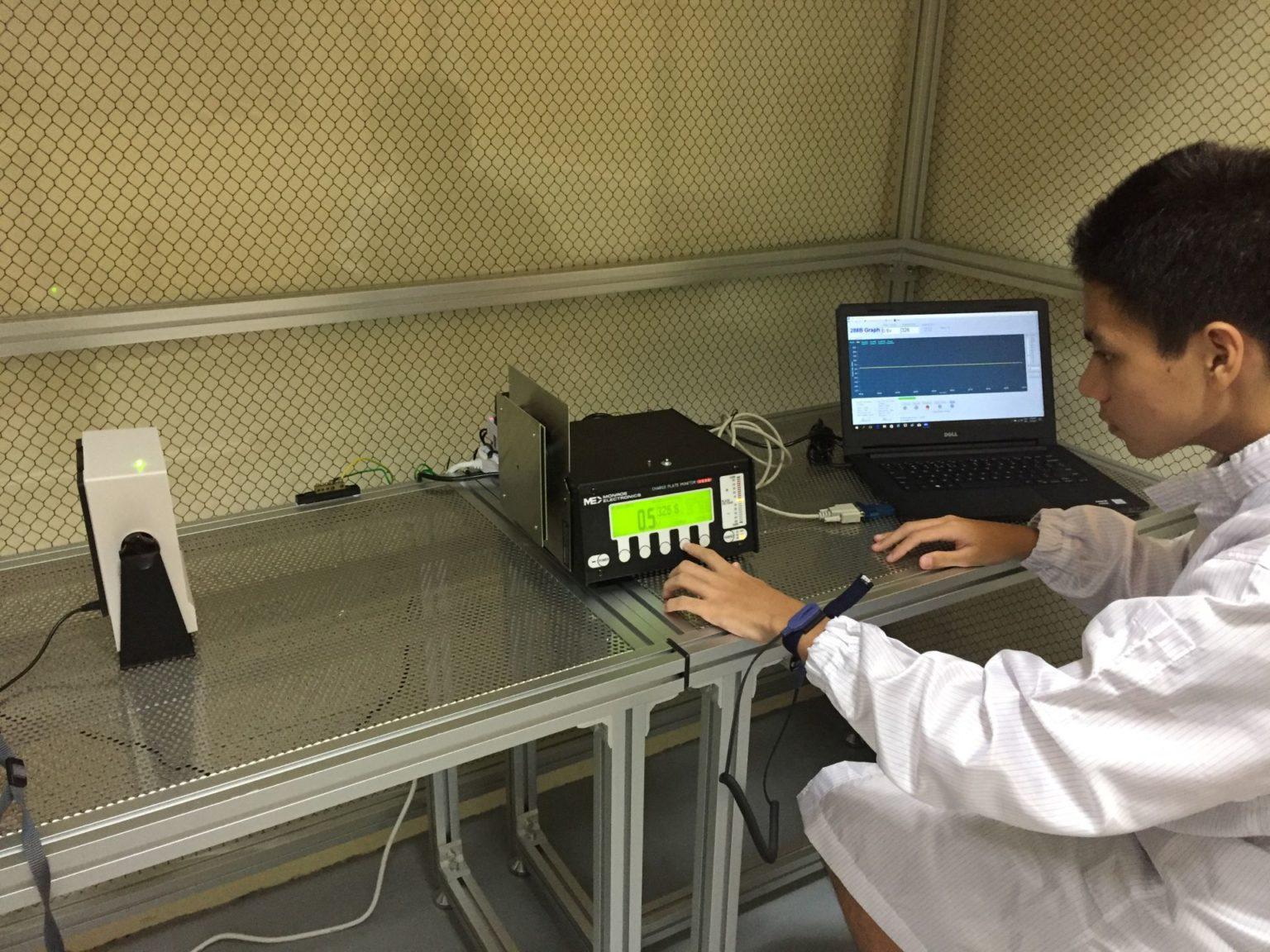

The Job of an ESD Eye

Electrostatic risks can be found and stopped with the help of an ESD device. These gadgets are always checking to see if people and things are properly grounded. ESD monitors give workers real-time confidence that they are safe to handle sensitive materials, unlike checks that are done only once in a while.

ESD Assessment: Looking at Vulnerabilities

An ESD assessment is often done by industries before putting ideas into action. This requires a full inspection of the workplace to find areas of constant risk and make sure that limits are working.

Building a long-term plan for the static control monitoring program

A static control monitoring tool does more than just one-time checks; it sets up a structured way to handle ESD risks.

Equipment to Help Keep an Environment Under Control

ESD monitors and programs are the most important parts of static safety, but there are other tools that can be used to make a safety plan more complete.

1. A hoover that can carry fumes

Harmful fumes are an unseen danger in places like factories, labs, and soldering irons. This is how a Portable fume extractor can help:

· Getting rid of harmful particles and gases where they come from. Allowing different desks to be mobile.

· Improving worker health and the cleanliness of the air.

In electronics production, where soldering fumes can hurt workers and damage sensitive equipment, these tools are very useful.

2. Particle Counter in the Air

In the aerospace, pharmaceutical, and semiconductor businesses, cleanroom requirements are very important. A counter for airborne particles measures the amount of pollution in real time. This makes sure that the ISO cleanliness standards are met and helps keep the area free of dust that could damage parts.

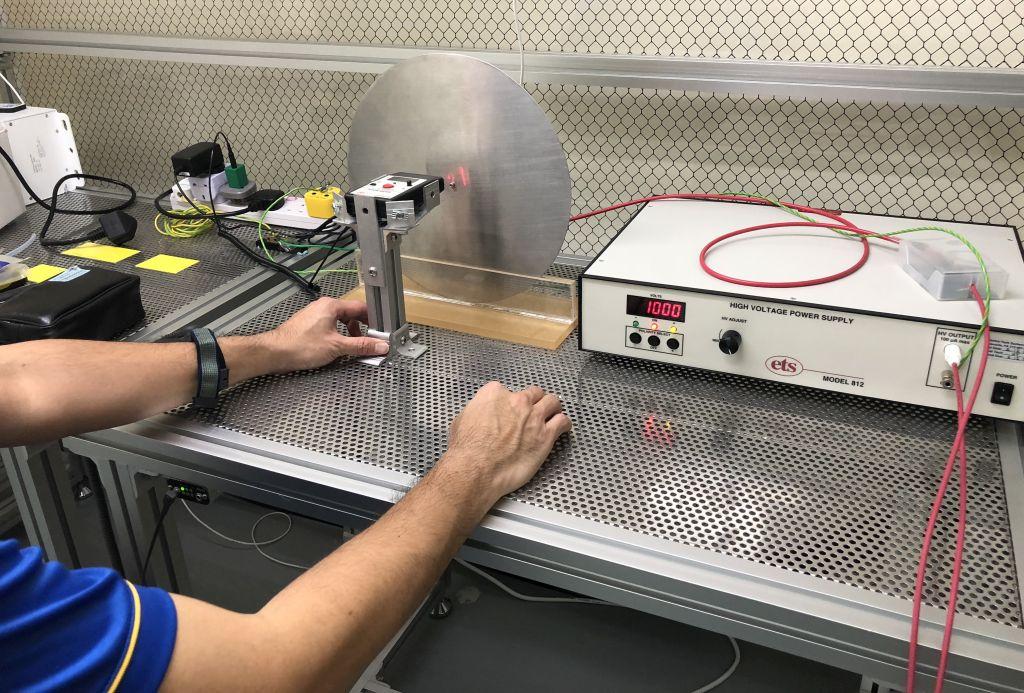

3. An ioniser

When working with insulators or other places where grounding isn't possible, you need an ioniser. By putting out positive and negative ions into the air, these gadgets cancel out static charges.

Ionisers can be used for the following:

· Assembly lines for electronics to keep connections safe.

· Cleanrooms to stop particles from sticking together.

· Plastics in packaging places cause static electricity to build up.

Ionisers help keep conditions safe and consistent at different steps of production by cancelling out charges.

Using technology to make workplaces safer

Putting all of these options together in one ecosystem is the best way to protect against ESD:

• ESD watches for operator grounding in real time.

• ESD checks to see where the holes are.

• Monitoring tools for static control that work well for a long time.

• Safe places to store energy like lithium battery cabinet.

• Portable fume extractors and airborne particle counters to make places healthy.

• Ionisers to get rid of electric charges that can't be avoided.

These systems work together to keep workers and goods safe and make sure that world safety standards are met.

Conclusion

Modern tech firms value safety and precision. Environmental or ESD issues can lead to product failures, regulatory fines, and worker accidents. Safety, dependability, and future readiness can be improved by purchasing ESD monitors, conducting ESD assessments, developing a static control monitoring program, and providing lithium battery cabinets, portable fume extraction devices, airborne particle counters, and ionisers.