Unpacking the Explosive 3D Simulation Software CAGR

The projected 3D Simulation Software CAGR (Compound Annual Growth Rate) of 17.20% is a powerful testament to the technology's escalating importance across the global industrial landscape. This exceptionally high, double-digit growth rate signifies a market that is not just expanding, but is in a state of hyper-acceleration, driven by a perfect storm of technological advancement and pressing business needs. This rapid pace of adoption is expected to propel the market to a massive valuation of USD 33.87 Billion by 2034, marking a profound shift in how products are designed, tested, and manufactured. This explosive growth is not attributable to a single factor but is the result of several powerful, interconnected drivers, including the rise of Industry 4.0, the imperative to reduce R&D costs, and the increasing complexity of modern products, all demanding a "shift left" approach to development.

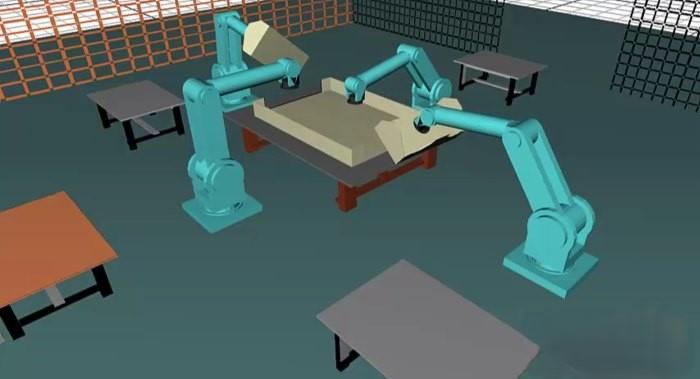

A primary engine behind this remarkable CAGR is the global push towards Industry 4.0 and the creation of "digital twins." A digital twin is a dynamic, virtual representation of a physical asset or system that is updated in real-time with data from IoT sensors. 3D simulation software is the foundational technology that creates and animates these digital twins, allowing companies to monitor, predict, and optimize the performance of their products and production lines remotely. This capability enables predictive maintenance, improves operational efficiency, and creates a continuous feedback loop between the real and virtual worlds. As more industries embrace the transformative potential of digital twins—from smart factories to intelligent infrastructure—the demand for the underlying simulation technology is skyrocketing, providing a powerful and sustained tailwind for market growth.

Another critical catalyst for this high-growth trajectory is the intense economic pressure on companies to accelerate innovation while simultaneously reducing research and development (R&D) costs. The traditional product development cycle, which relies heavily on building and testing multiple physical prototypes, is incredibly slow, expensive, and wasteful. 3D simulation software fundamentally disrupts this model. By enabling engineers to perform thousands of virtual tests on a computer, it drastically cuts down on the need for physical prototypes, saving millions of dollars in material and manufacturing costs. This "virtual prototyping" also allows for much faster design iteration, enabling companies to explore more innovative ideas and bring superior products to market ahead of their competitors. The clear and compelling ROI of simulation is a major reason for its rapid and widespread adoption.

Furthermore, the increasing complexity of modern products makes advanced simulation a necessity rather than a luxury. Today’s products, from smartphones to electric vehicles, are highly sophisticated systems that integrate complex electronics, software, and advanced materials. It is virtually impossible to predict how these intricate systems will interact and perform under real-world conditions without the aid of multi-physics simulation. For example, designing an electric vehicle requires simulating the interplay between the battery's thermal management, the electric motor's electromagnetic fields, and the vehicle's structural integrity. The ability of 3D simulation software to model and analyze these complex, interconnected systems is indispensable for modern product development, ensuring its continued and rapid growth across all advanced engineering sectors and driving its impressive CAGR.

Explore Our Latest Trending Reports: