Forging the Future: A Comprehensive Analysis of the Metal Fabrication Market and Forecast to 2032

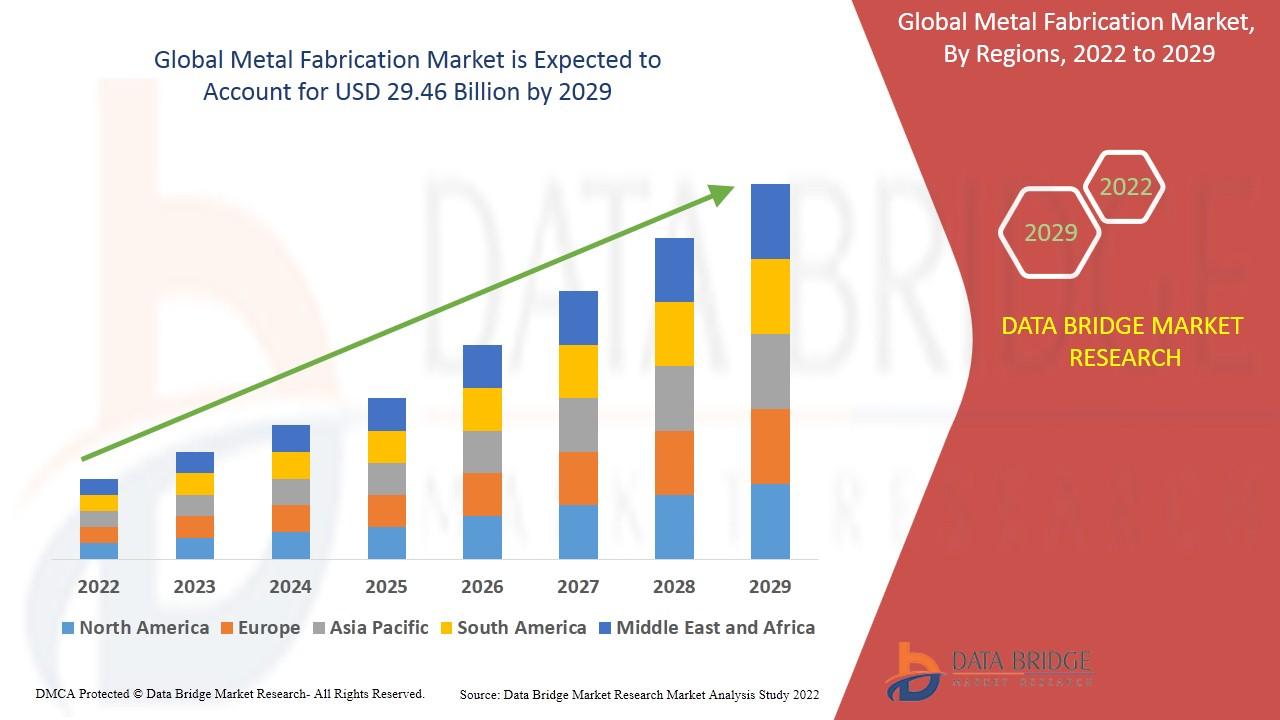

Global metal fabrication market size was valued at USD 22.95 billion in 2024 and is projected to reach USD 33.15 billion by 2032, with a CAGR of 4.70% during the forecast period of 2025 to 2032.

The global metal fabrication industry serves as the backbone of modern industrial operations, powering a wide range of applications from automotive and aerospace to construction, energy, defense, and consumer goods. Metal fabrication involves processes such as cutting, bending, welding, machining, and assembling to create parts and structures used in both heavy and light industries.

As economies continue to industrialize and advance technologically, the demand for metal fabrication services and products has grown significantly. Global supply chains, infrastructure investments, and manufacturing expansion have made this sector indispensable.

The industry also plays a critical role in driving innovation by enabling the production of lightweight structures, precision parts, and high-performance components that support advancements across multiple markets.

The sector is being shaped by the convergence of digital transformation, sustainability efforts, and increased demand for customized and complex metal products. With automation and advanced technologies, the industry is moving toward improved efficiency, precision, and cost-effectiveness, making it a dynamic and competitive global market.

Download The Market Report - https://www.databridgemarketresearch.com/reports/global-metal-fabrication-market

Market Trends

The global metal fabrication market is witnessing transformative trends driven by shifting industrial requirements, technological advancements, and global economic developments. One of the most notable trends is the adoption of automation and digital technologies such as robotics, computer numerical control (CNC) machining, and computer-aided design (CAD) software. These tools are enhancing productivity, accuracy, and scalability, reducing manual errors, and lowering production costs.

Sustainability has also emerged as a major trend. With growing awareness of environmental concerns and stricter regulatory frameworks, industries are increasingly adopting energy-efficient fabrication methods, recycling scrap metals, and reducing emissions throughout the production process. The emphasis on green manufacturing is reshaping operational strategies across leading players.

Another key trend is the demand for lightweight and high-strength materials. The automotive and aerospace industries, in particular, are pushing fabricators to develop components that reduce overall weight while maintaining durability and safety standards. The rise of electric vehicles (EVs) and renewable energy systems is accelerating this requirement, as fabricated metal parts are essential for batteries, turbines, and solar mounting structures.

The market is also experiencing a growing demand for customized solutions. As industries such as construction and manufacturing diversify, companies are looking for specialized fabricated products tailored to specific projects. This is giving rise to increased investments in flexible manufacturing systems and advanced design capabilities.

Global trade dynamics, particularly the availability and pricing of raw materials such as steel and aluminum, are also influencing the industry. Fluctuating raw material prices and supply chain disruptions have impacted production costs and timelines, making companies focus on diversification and strategic sourcing.

Market Size

The global metal fabrication market has expanded consistently over the past decade, supported by large-scale industrialization, infrastructure growth, and technological modernization. As of recent estimates, the market size is valued in the hundreds of billions of dollars, with steady growth across regions such as North America, Europe, and Asia-Pacific. The Asia-Pacific region dominates the market, largely due to the rapid industrial growth in China, India, South Korea, and Japan, coupled with strong demand from automotive, electronics, and construction industries.

North America represents another significant share, driven by technological adoption, advanced manufacturing practices, and robust demand from aerospace, defense, and energy sectors. Europe continues to play a vital role, with Germany, the UK, and Italy at the forefront of metalworking innovations, especially in precision engineering and automation.

Emerging economies are increasingly contributing to the global market as industrial development projects and infrastructure investments fuel demand for fabricated metals. As a result, the overall market size continues to expand, supported by innovation and global supply chain integration.

Browse More Reports

Global Automotive DC-DC Converters Market

Global Automotive Door Seal Market

Global Automotive Heat Exchanger Market

Global Automotive Interconnecting Shaft Market

Global Automotive Internet of Things (IoT) Market

Global Automotive Multi Axis Positions Sensors Market

Global Automotive Natural Gas Vehicle Market

Global Automotive Number Plate Market

Global Automotive Paints and Coatings Market

Global Automotive Rain Sensor Market

Global Automotive Refinish Coatings Market

Global Automotive Relay Market

Global Automotive Structural Steel Market

Global Autorefractor keratometer Device Market

Global Bariatric Patient Care Handling Equipment Market

Market Share

The market share distribution within the global metal fabrication industry is fragmented, with a mix of large multinational corporations, medium-sized firms, and small-scale local players. Large enterprises often dominate the market with their extensive manufacturing capabilities, global distribution networks, and technological investments. These players are able to cater to large-scale industrial projects, aerospace components, and automotive supply chains.

Meanwhile, small and medium-sized enterprises (SMEs) hold a substantial portion of the market share, particularly in customized fabrication services. These businesses specialize in niche markets and provide tailored solutions, giving them a competitive edge in regions with diverse industrial needs.

Regionally, Asia-Pacific commands the largest share, primarily due to cost advantages, strong demand from manufacturing industries, and a rapidly expanding infrastructure sector. North America and Europe also maintain considerable market shares, with a focus on advanced technologies, quality standards, and sustainable operations. Middle Eastern and African markets, while smaller, are emerging as promising regions due to infrastructure development projects and growing industrial activity.

Market Growth

The growth trajectory of the global metal fabrication market is shaped by both macroeconomic and microeconomic drivers. Industrialization in emerging markets is a key factor, as urbanization and infrastructure expansion boost demand for fabricated metal products in construction, transportation, and energy. In developed markets, the demand is fueled by technological innovations, sustainability initiatives, and advanced manufacturing practices.

The automotive industry continues to be a major driver of growth, particularly with the transition toward electric vehicles. Lightweight fabricated metal parts are vital in EV manufacturing, creating strong demand across the supply chain. Similarly, the aerospace and defense sectors require precision fabrication for high-performance components, contributing to steady growth.

Energy and power generation projects, including wind, solar, and nuclear, rely heavily on fabricated metal structures, further driving market growth. The oil and gas industry also plays a significant role, particularly in terms of pipelines, rigs, and structural components.

The adoption of Industry 4.0 practices such as IoT integration, real-time monitoring, and smart manufacturing is accelerating growth by improving efficiency and lowering costs. The emphasis on digital twins and simulation technologies also supports faster innovation cycles in fabrication processes.

Market Demand

Market demand for metal fabrication is diverse and strong across industries. Construction remains one of the largest demand drivers, with fabricated metals used extensively in structural frameworks, beams, and reinforcements. Rapid urbanization, coupled with government investments in infrastructure, is fueling demand for construction-grade fabricated metals.

In the automotive sector, demand is being driven by both traditional internal combustion engine vehicles and electric vehicles. Fabricated metals are essential for engine components, chassis, and lightweight parts that improve fuel efficiency. Aerospace is another high-demand sector, with stringent requirements for lightweight, durable, and precisely fabricated parts.

Energy and renewable sectors are driving substantial demand, as fabricated metals are integral to turbines, solar panel frames, and offshore energy structures. In addition, consumer goods and electronics industries are increasingly relying on fabricated metals for product enclosures, structural components, and design features.

The rise of defense spending in several countries is another factor fueling demand, as militaries require fabricated equipment, vehicles, and weaponry systems. Collectively, this wide spectrum of industries ensures that the demand for metal fabrication remains resilient and continues to grow.

Market Future Insights

Looking ahead, the future of the global metal fabrication market appears promising, with significant opportunities for innovation, expansion, and diversification. The integration of advanced technologies such as artificial intelligence (AI), machine learning, and robotics will further enhance precision, efficiency, and scalability. Digital platforms will support supply chain transparency, predictive maintenance, and improved quality control, driving competitiveness.

Sustainability will continue to be a major focus, with manufacturers adopting green fabrication practices, recycling scrap, and minimizing carbon footprints. Governments and industries alike are pushing for eco-friendly manufacturing, which will reshape operational models. The rise of additive manufacturing and 3D printing is also expected to complement traditional fabrication techniques, particularly in producing complex, lightweight components.

Global infrastructure development, particularly in emerging markets, will generate massive demand for fabricated metals in construction and energy. Additionally, the shift toward renewable energy systems and electric mobility will expand the market for specialized fabricated components.

While challenges such as raw material price volatility and supply chain disruptions will persist, innovation, strategic sourcing, and global collaboration will mitigate risks. The industry is poised for continued growth, with opportunities for both established players and emerging enterprises to thrive.

Conclusion

The global metal fabrication market is evolving rapidly, fueled by industrial expansion, sustainability goals, and technological advancements. From construction and automotive to aerospace and renewable energy, demand for fabricated metals is diverse and strong. With digitalization, automation, and green practices leading the way, the sector is set to achieve robust growth and play a crucial role in shaping the future of industrial manufacturing worldwide.

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

Metal Fabrication Market, Metal Fabrication Market Trends, Metal Fabrication Market Growth, Metal Fabrication Market Demand, Metal Fabrication Market Size, Metal Fabrication Market Scope, Metal Fabrication Market Insights, Metal Fabrication Market Analysis,