Global Pneumatic Conveying System Market Outlook 2025-2033: Trends and Growth Analysis

MARKET OVERVIEW

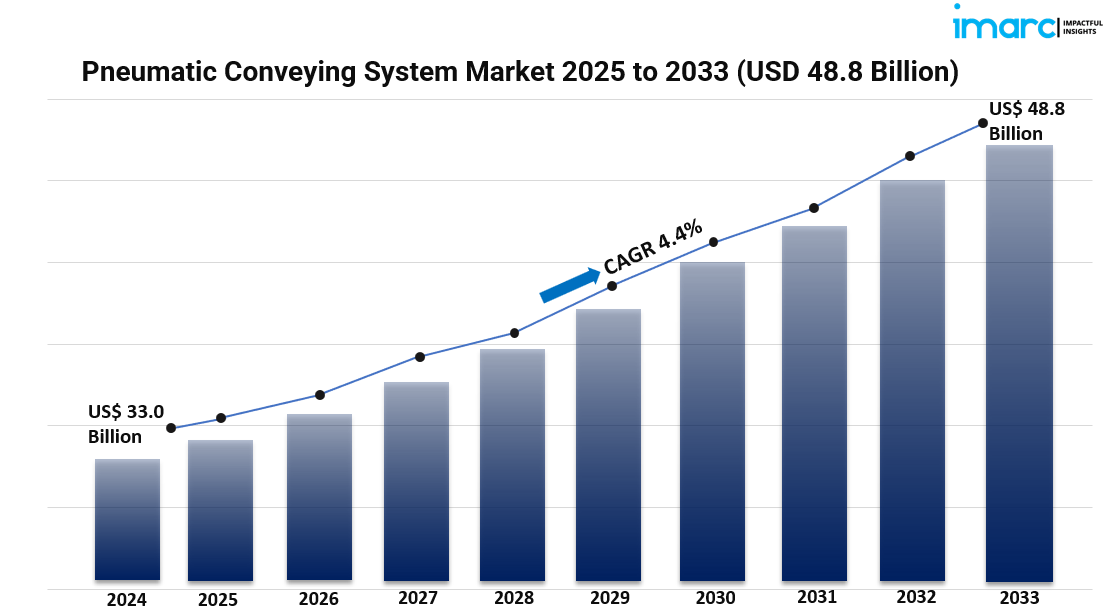

The global pneumatic conveying system market is witnessing strong growth, projected to rise from USD 33.0 billion in 2024 to USD 48.8 billion by 2033, reflecting a CAGR of 4.4%. This expansion is driven by increased automation, adoption of energy-efficient solutions, and rising applications across the pharmaceutical and mining sectors.

STUDY ASSUMPTION YEARS

- BASE YEAR: 2024

- HISTORICAL YEAR: 2019 - 2024

- FORECAST YEAR: 2025 - 2033

Pneumatic Conveying System Market Key Takeaways

- Current Market Size & Growth: Valued at USD 33.0 billion in 2024 and expected to reach USD 48.8 billion by 2033 at a CAGR of 4.4%.

- Regional Leader: Asia Pacific leads the market with over 30.5% share in 2024, followed closely by North America.

- By Operation: Dilute-phase conveying remains dominant due to cost-effectiveness and versatility.

- By Technology: Positive pressure systems lead, enabling seamless long-distance transport.

- By End-Use: Food and pharmaceuticals are key end-users, driven by hygiene and contamination-free handling requirements.

- Drivers of Expansion: Trends such as automation (Industry 4.0), energy-efficiency, and dense-phase system innovations support market growth.

Request for a sample copy of this report: https://www.imarcgroup.com/pneumatic-conveying-system-market/requestsample

MARKET GROWTH FACTORS

- Rising Demand from Pharmaceutical & Food Sectors

Pneumatic systems are increasingly employed in pharmaceuticals for transporting APIs, powders, granules, and during tablet compression, ensuring accuracy, hygiene, and contamination control. In the food industry, these systems support dust-free handling of flour, sugar, cereals, spices, and other ingredients. The rising consumption of processed foods and growth in pharmaceutical production are significant drivers for market expansion. - Technological Innovation & Automation Integration

Investments in research and development have led to advancements such as vacuum systems, modular designs, SCADA/PLC/HMI integration, and dense-phase conveying. These solutions reduce energy use, material degradation, and downtime. IoT-enabled sensors allow real-time monitoring and predictive maintenance, particularly in sectors with strict quality standards like food and pharmaceuticals, thereby improving efficiency and reliability. - Energy Efficiency & Sustainability Focus

The demand for energy-efficient pneumatic systems is increasing due to environmental awareness and cost considerations. Technologies including variable-speed drives and energy-recovery devices are widely adopted. Dense-phase systems operate at lower velocities, reducing emissions and material degradation. Closed-loop architectures minimize dust and waste, supporting sustainability and regulatory compliance.

MARKET SEGMENTATION

Breakup by Operation

- Dilute Phase Conveying

- Dense Phase Conveying

Breakup by Technology

- Positive Pressure Systems

- Vacuum Systems

- Combination Systems

Breakup by End-Use

- Ceramic

- Pharmaceuticals

- Food Industry

- Rubber and Plastic

- Cement

- Mining (Mineral)

- Automotive

- Others

Breakup by Region

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

REGIONAL INSIGHTS

Asia Pacific dominates the market with over 30.5% share in 2024. Rapid industrialization in food processing, pharmaceuticals, mining, and manufacturing, particularly in China, India, and Japan, drives demand. Investments in automation, expansion of production infrastructure, and focus on efficient material handling further contribute to market growth.

RECENT DEVELOPMENTS & NEWS

Recent industry trends include the adoption of dense-phase systems, which improve handling of fragile and abrasive bulk materials while using less energy. Modular and flexible designs are gaining popularity, allowing scalability and quick reconfiguration. Vacuum conveying is being increasingly used for gentle transfers of sensitive powders. SCADA/PLC/HMI-integrated automated systems, featuring real-time data analytics and remote control, are also being deployed to boost productivity and reduce unplanned downtime.

KEY PLAYERS

- Atlas Copco AB

- Coperion GmbH

- Cyclonaire Corporation

- Dongyang P & F

- Dynamic Air Inc.

- Flexicon Corporation

- Gericke AG

- VAC‑U‑MAX

- Schenck Process Holding GmbH

- Pneumatic Conveying, Inc.

- Nol‑Tec Systems Inc.

- Nilfisk Group

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Request for Customization: https://www.imarcgroup.com/request?type=report&id=5108&flag=E

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302