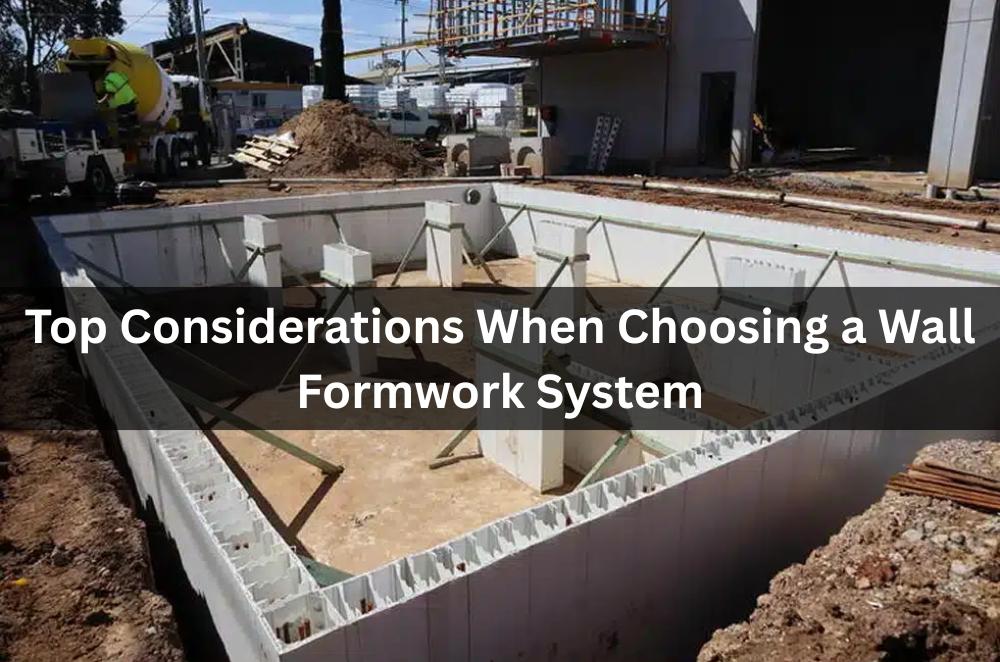

Top Considerations When Choosing a Wall Formwork System

Choosing a wall formwork system isn’t just a materials call—it’s a decision that affects speed, finish quality, safety, and overall cost across the project. On most jobs, the smartest place to start is with real-world buildability: crane access, crew skill mix, pour sequences, and how the system behaves when weather turns. From there, compare modularity, tie layouts, and reusability against the scale of your programme. When those puzzle pieces align, you pour faster and patch less. For teams scoping options, wall formwork solutions often act as a reference point for moisture management, panel robustness, and compatible hardware across different wall geometries.

Load paths and panel selection

Wall formwork must move concrete’s weight cleanly into props, ties, and the slab or ground. Miss the load path, and you invite deflection, honeycombing, and schedule pain.

-

Design pressure: Size panels and ties to the expected rate of rise so fresh concrete pressure stays within limits.

-

Stud spacing: Match rib geometry to panel spans so deflection stays tight and face sheets remain true.

-

Tie capacity: Choose tie systems that hold alignment through vibration and staged pours without creep.

-

Edge detailing: Specify corners and stop-ends that lock square without field improvisation.

Shortlist systems with clear data sheets and tested assemblies. The goal is a predictable pour window where crews can focus on placement and consolidation rather than firefighting alignment drift.

Finish class, rebar congestion, and tie patterns

Surface class targets (from utilitarian to architectural) should drive panel skins, joint treatment, and the tolerance you can practically maintain. Congested reinforcement demands smart tie layouts, slim hardware, and dependable vibration paths. To ground this in a broader industry context, align your material and process choices with concrete manufacturing standards that emphasise consistency, controlled placement, and material efficiency.

-

Face materials: Select plywood, HDO, or composite skins to suit reuse count and target finish class without excessive patching.

-

Joint control: Use gaskets or sealants to minimise fins and slurry leakage at panel interfaces.

-

Tie spacing: Balance structural needs with patch count by coordinating tie lines with rebar and architectural sightlines.

-

Vibration access: Ensure internal or external vibration can reach congested zones without trapping air.

Treat the pour like choreography: placement, vibration, and strike-off should read as a single sequence. When ties, bars, and vibration paths cooperate, you get cleaner faces and quicker demoulds.

Waterproofing, durability, and movement joints

Water-facing walls, basements, and retaining structures live or die by detailing. The formwork system should enable clean waterstop placement, consistent cover, and controlled joint formation.

-

Waterstop seating: Form rebates and chairs so hydrophilic or PVC waterstops sit straight and stay undisturbed during pour.

-

Cover assurance: Use spacers and inspection checks that hold reinforcement off face sheets despite vibration.

-

Joint planning: Cast movement and construction joints where the structure can tolerate them, not where the formwork forces them.

-

Cure protection: Plan demould and early cure to protect edges and arrises from wind and sun, preserving durability.

Durability is often a story of tiny alignments done well. When covers, joints, and curing align, your maintenance curve flattens and post-pour interventions shrink.

Productivity, logistics, and crew safety

Time on a live site burns budget fast. Systems that lift in logical modules, stack neatly, and accept standard hardware save hours every shift. Crew safety tracks closely with predictability.

-

Modularity: Choose panel sizes that marry crane picks with manual handling limits for smaller tweaks.

-

Fasteners logic: Standardise pins and clips so crews don’t hunt for niche parts at 5 am.

-

Access planning: Integrate platforms, ladders, and edge protection so strikes and sets aren’t improvised.

-

Cycle time: Measure set, pour, and strip durations against crane availability to smooth the daily curve.

Continuous improvement comes from small wins: a better stacking pattern, faster tie release, or a site kit that keeps spares within arm’s reach. Over weeks, those minutes add up to days.

In-situ practicalities and method selection

In tight footprints or irregular geometry, in-situ sequencing can outperform pre-assembled frames—if you plan the method early and match it to crew skills. For deeper technique planning, crews often benchmark in-situ formwork methods to decide where jump forms, modular panels, or custom shutters make the most sense.

-

Geometry fit: Select systems that flex around offsets, pilasters, and embedded items without cutting corners on tolerances.

-

Set-out clarity: Use grid lines, laser levels, and checklists so plumb and level are confirmed before the pour starts.

-

Penetrations plan: Pre-coordinate sleeves, boxes, and blockouts with trades so no one is drilling the day after the pour.

-

Strike sequence: Plan release order to avoid binding, protect corners, and keep the programme moving.

Good method selection reduces stress. When the sequence is clear and tools are standard, crews settle into a rhythm that survives weather and schedule pressure.

Curing strategy, weather, and thermal control

Curing is where good pours become a durable structure. Heat, wind, and sun can undo tidy formwork work unless you plan for them.

-

Moisture retention: Use curing compounds or covers that fit the finish class and don’t fight subsequent coatings.

-

Thermal gradients: Watch temperature differentials in thick walls; manage with pour timing and insulation where needed.

-

Strike timing: Balance early progress with strength gain so edges and tie holes don’t spall.

-

Protection plan: Shield fresh faces from rain streaks or dust so patching lists don’t swell on day two.

Treat weather as a design load. If the plan assumes calm conditions, the first hot wind will write your defect list for you.

Quality control and documentation that actually helps

Paperwork should make life easier, not thicker. Focus on records that catch drift early and prove compliance without slowing down crews.

-

Pre-pour checks: Ties, anchors, alignments, and embeds ticked off by a second set of eyes.

-

Pour logs: Start/finish times, rate of rise, and any hold points noted against zones.

-

Strike notes: Defects mapped to a grid so patchers know exactly where to go—no mystery hunts.

-

Lessons learned: Short, honest notes that feed tomorrow’s toolbox talk with one improvement at a time.

When QC is lean and visual, the site spends less time arguing and more time building.

The practical shortlist (final considerations)

Every site is different, but the winning pattern repeats. Start with structural basics—load paths, tie capacity, and panel stiffness—so the wall stays true under pressure. Let's finish targets, drive skin selection, and tie spacing, especially where rebar is dense. Keep waterproofing details simple to install and hard to disturb. Choose a system that moves smoothly through the site: modules that match crane cycles, hardware that crews know, and platforms that feel natural underfoot. Sequence the work with realistic rates of rise, vibration access, and strike order so defects don’t creep in at the edges when everyone is tired. Use lean documentation that catches drift early and proves compliance without drowning the day in forms. If you want a broad, visual refresher as you wrap your shortlist, concrete formwork systems offer a helpful overview of component logic and use-cases. In the end, the best wall formwork choice is the one your crew can set, pour, and strike predictably—rain or shine—delivering straight, tight faces with minimal patching and a programme that stays on beat.