How Ceramic Heating Elements Work: A Complete Guide

Ceramic heating elements are essential components in modern heating technology. Known for their efficiency, safety, and durability, they are used in a wide range of applications—from hair dryers and space heaters to industrial furnaces. But how exactly do ceramic heating elements work? In this article, we’ll break down their mechanism, components, and benefits to help you understand why they are preferred over traditional heating methods.

What Is a Ceramic Heating Element?

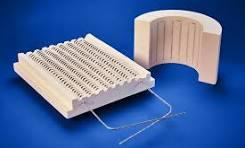

A ceramic heating element is a type of heater made using ceramic materials, such as aluminum oxide (Al₂O₃) or silicon carbide. These materials are known for their high thermal conductivity and electrical insulation properties. The heating element typically consists of a resistive wire (like nichrome) embedded in a ceramic insulator or matrix. When electricity passes through the resistive wire, it generates heat, which is then transferred to the ceramic material and radiated outward.

To explore quality heating products and get more technical insights, you can visit this ceramic heating element resource.

How Does a Ceramic Heating Element Work?

Let’s walk through the step-by-step process of how ceramic heating elements generate and distribute heat:

1. Electricity Flows Through the Resistive Wire

The core component of the heating element is a resistive metal coil, often made from nichrome. When electrical current is supplied, the resistance of the metal causes it to heat up due to the Joule heating effect (also known as resistive heating).

2. Heat Transfers to the Ceramic

The resistive wire is either embedded in or wrapped around a ceramic material. The ceramic acts as both an electrical insulator and a thermal conductor. It absorbs the heat from the wire and evenly distributes it across its surface.

3. Radiant and Convective Heat Distribution

Once the ceramic reaches a specific temperature, it emits infrared radiation, warming the surrounding air or objects directly. Additionally, air moving over the heated ceramic carries heat through convection, enhancing its ability to raise ambient temperature efficiently.

4. Temperature Regulation and Safety

Many ceramic heating elements come equipped with built-in thermostats or thermistors that regulate temperature. This prevents overheating, improves energy efficiency, and adds a layer of safety—making them ideal for domestic and industrial applications alike.

Types of Ceramic Heating Elements

There are several variations of ceramic heating elements, each suited for different use cases:

● PTC Ceramic Heaters

Positive Temperature Coefficient (PTC) elements self-regulate their temperature. As they heat up, their electrical resistance increases, naturally reducing current flow and limiting temperature rise—eliminating the need for external thermostats in many cases.

● MCH (Metal Ceramic Heater)

These use printed metal circuits on a ceramic substrate, ideal for applications that require precise, uniform heating like medical devices and lab equipment.

● Ceramic Infrared Heaters

Used in industrial heating and drying processes, these heaters emit infrared radiation to provide heat without direct contact, allowing for uniform heating over large areas.

Advantages of Using Ceramic Heating Elements

Ceramic heaters offer numerous benefits compared to conventional metal-based heating systems:

✔️ Energy Efficiency

Ceramic materials retain heat longer, allowing for lower energy consumption once the desired temperature is reached.

✔️ Fast Heating

The high thermal conductivity of ceramics enables rapid temperature rise, making these heaters quick to respond.

✔️ Safety

Ceramic elements do not get as hot on the surface as metal coils, reducing the risk of burns or fire hazards.

✔️ Durability

Ceramics are highly resistant to oxidation and wear, making them ideal for long-term use in both harsh and domestic environments.

✔️ Compact Design

They can be manufactured in smaller, more versatile shapes—perfect for portable heaters and space-saving installations.

Applications of Ceramic Heating Elements

Thanks to their versatility and reliability, ceramic heating elements are found in a wide variety of industries:

-

Home Appliances: Space heaters, hair dryers, and irons

-

Automotive: Seat warmers, engine pre-heaters

-

Industrial: Plastic welding, drying systems, semiconductor processing

-

Medical: Sterilization tools, incubators

Choosing the Right Ceramic Heating Element

When selecting a ceramic heating element, consider the following factors:

-

Wattage and Voltage Requirements

-

Temperature Range

-

Heating Time

-

Size and Mounting Options

-

Environmental Conditions (e.g., humidity, exposure to chemicals)

For high-quality and customizable ceramic heater options, check out Jobco Supply’s ceramic heating element catalog. Their range includes options suitable for both consumer and industrial-level heating needs.

Conclusion

Ceramic heating elements work through a combination of electrical resistance and thermal conduction, offering efficient, safe, and rapid heating. Whether you're upgrading a home appliance or outfitting an industrial machine, understanding how ceramic heaters work helps ensure you choose the most effective solution.

From compact consumer devices to complex industrial systems, the ceramic heating element continues to play a vital role in modern heating technology. If you're looking for durable and efficient heating solutions, Jobco Supply is a trusted source worth exploring.