Precision and Innovation with Raamps Industries: Your Trusted Laser Cutting Services Provider

In today’s fast-paced manufacturing world, precision, speed, and quality are non-negotiable. Whether it’s for automotive, aerospace, construction, or custom fabrication, the demand for Laser Cutting Services has grown exponentially. At Raamps Industries, we combine advanced technology with expert craftsmanship to deliver unmatched accuracy and efficiency in every project. As a leading Laser Cutting Services Provider, our focus is to turn complex designs into flawless products with precision you can trust.

Why Choose Laser Cutting Services?

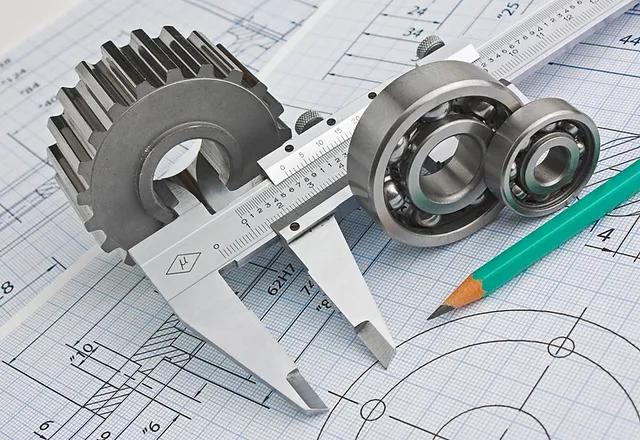

Laser cutting has revolutionized modern manufacturing. It uses high-powered lasers to cut through materials like metal, stainless steel, and aluminum with extreme accuracy. The advantages include:

Precision and Consistency: Laser cutting delivers clean edges and detailed cuts without the need for secondary finishing.

Efficiency: High-speed cutting reduces production time and costs.

Versatility: Suitable for a wide range of materials and thicknesses.

Minimal Waste: The precision of laser cutting ensures maximum material utilization.

At Raamps Industries, we harness these benefits to help our clients achieve higher production efficiency and consistent quality.

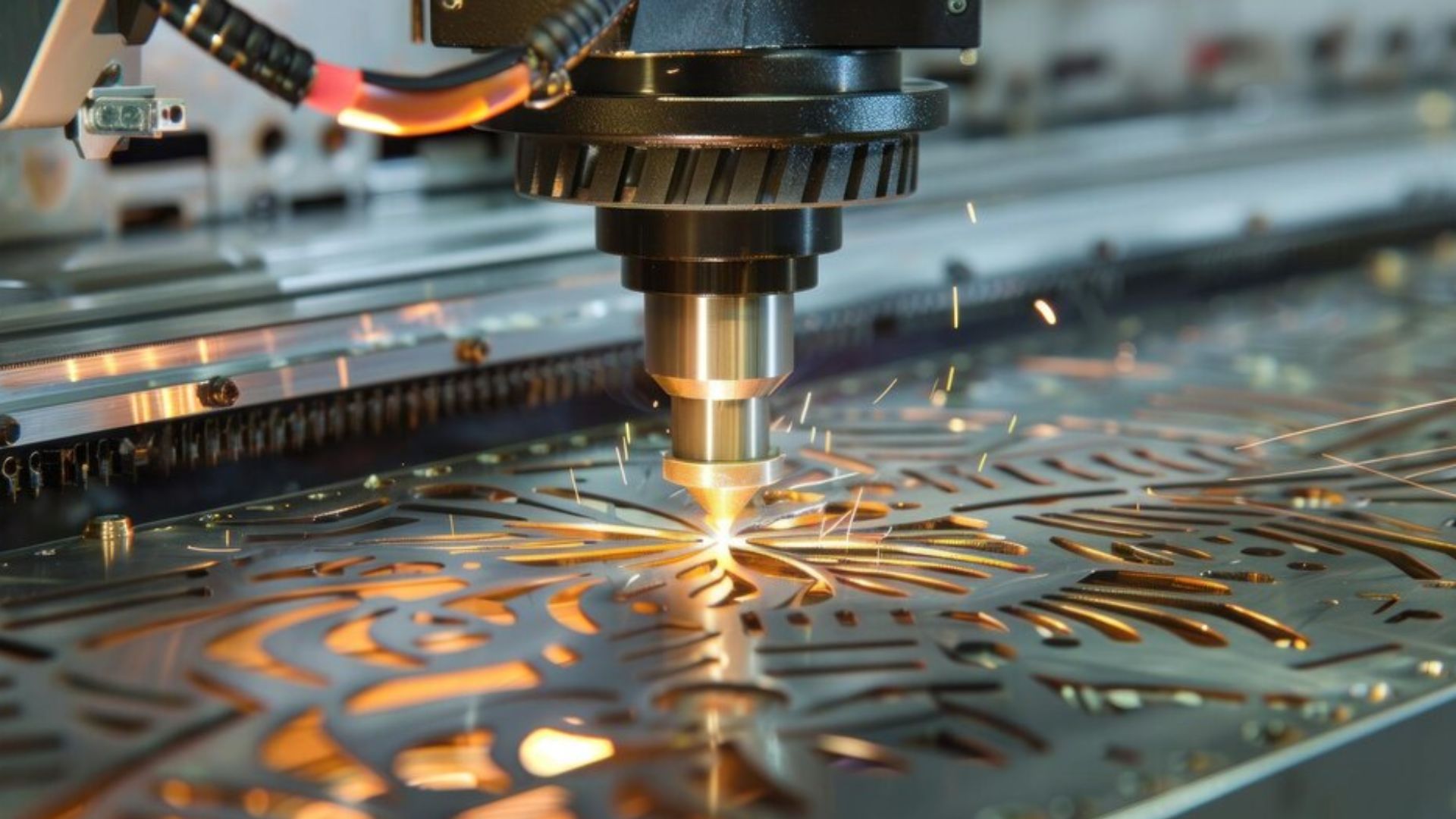

Sheet Metal Laser Cutting at Raamps Industries

When it comes to Sheet Metal Laser Cutting, precision and reliability are essential. Our state-of-the-art laser cutting machines handle complex geometries and intricate designs with ease. Whether you need small prototype batches or large-scale production runs, our advanced machinery ensures accurate and repeatable results every time.

We specialize in:

Mild Steel, Stainless Steel, and Aluminum cutting

Customized component fabrication

Prototyping and mass production

Tight tolerance and high-quality finishing

Every project at Raamps Industries is managed with attention to detail and a commitment to meeting deadlines without compromising on quality.

Why Raamps Industries is the Right Laser Cutting Services Provider for You

Choosing the right Laser Cutting Services Provider can make all the difference in your manufacturing process. Raamps Industries stands out through:

Advanced Technology: Equipped with the latest CNC laser cutting systems.

Skilled Team: Experienced engineers and technicians dedicated to precision.

Quality Assurance: Rigorous inspection ensures that every piece meets your exact specifications.

Customer Focus: We work closely with clients to understand their unique needs and deliver tailored solutions.

Our mission is to provide cutting-edge Laser Cutting Services that empower businesses to innovate and grow.

Conclusion

When precision, performance, and reliability matter most, Raamps Industries is your trusted partner for all Laser Cutting Services. With our expertise in Sheet Metal Laser Cutting and advanced laser technology, we deliver solutions that exceed expectations. Whether you’re looking for a dependable Laser Cutting Services Provider for custom projects or large-scale production, Raamps Industries ensures quality you can see and precision you can rely on.

https://www.raampsindustries.com/services/laser-cutting/

Precision and Innovation with Raamps Industries: Your Trusted Laser Cutting Services Provider

In today’s fast-paced manufacturing world, precision, speed, and quality are non-negotiable. Whether it’s for automotive, aerospace, construction, or custom fabrication, the demand for Laser Cutting Services has grown exponentially. At Raamps Industries, we combine advanced technology with expert craftsmanship to deliver unmatched accuracy and efficiency in every project. As a leading Laser Cutting Services Provider, our focus is to turn complex designs into flawless products with precision you can trust.

Why Choose Laser Cutting Services?

Laser cutting has revolutionized modern manufacturing. It uses high-powered lasers to cut through materials like metal, stainless steel, and aluminum with extreme accuracy. The advantages include:

Precision and Consistency: Laser cutting delivers clean edges and detailed cuts without the need for secondary finishing.

Efficiency: High-speed cutting reduces production time and costs.

Versatility: Suitable for a wide range of materials and thicknesses.

Minimal Waste: The precision of laser cutting ensures maximum material utilization.

At Raamps Industries, we harness these benefits to help our clients achieve higher production efficiency and consistent quality.

Sheet Metal Laser Cutting at Raamps Industries

When it comes to Sheet Metal Laser Cutting, precision and reliability are essential. Our state-of-the-art laser cutting machines handle complex geometries and intricate designs with ease. Whether you need small prototype batches or large-scale production runs, our advanced machinery ensures accurate and repeatable results every time.

We specialize in:

Mild Steel, Stainless Steel, and Aluminum cutting

Customized component fabrication

Prototyping and mass production

Tight tolerance and high-quality finishing

Every project at Raamps Industries is managed with attention to detail and a commitment to meeting deadlines without compromising on quality.

Why Raamps Industries is the Right Laser Cutting Services Provider for You

Choosing the right Laser Cutting Services Provider can make all the difference in your manufacturing process. Raamps Industries stands out through:

Advanced Technology: Equipped with the latest CNC laser cutting systems.

Skilled Team: Experienced engineers and technicians dedicated to precision.

Quality Assurance: Rigorous inspection ensures that every piece meets your exact specifications.

Customer Focus: We work closely with clients to understand their unique needs and deliver tailored solutions.

Our mission is to provide cutting-edge Laser Cutting Services that empower businesses to innovate and grow.

Conclusion

When precision, performance, and reliability matter most, Raamps Industries is your trusted partner for all Laser Cutting Services. With our expertise in Sheet Metal Laser Cutting and advanced laser technology, we deliver solutions that exceed expectations. Whether you’re looking for a dependable Laser Cutting Services Provider for custom projects or large-scale production, Raamps Industries ensures quality you can see and precision you can rely on.

https://www.raampsindustries.com/services/laser-cutting/