Butt Fusion Machine Dubai: High-Precision Welding Solutions for HDPE Infrastructure Projects

In Dubai's rapidly expanding infrastructure sector, the need for durable and leak-proof piping systems has never been greater. As urban development accelerates and mega projects rise across the emirate, reliable HDPE (High-Density Polyethylene) piping networks are essential for water, gas, and wastewater systems. These pipelines demand secure, permanent joints that can withstand extreme weather, pressure variations, and chemical exposure. This is where butt fusion welding comes into play, offering a highly effective solution for creating seamless connections in HDPE pipes.

Butt fusion is a thermoplastic welding technique that involves heating the ends of two pipes and pressing them together until they fuse into a single, homogenous joint. This process ensures leak-proof, corrosion-resistant, and long-lasting performance, making it ideal for critical infrastructure applications. Choosing a butt fusion machine Dubai allows contractors and engineers to meet local construction standards while ensuring precision, efficiency, and compliance with international safety protocols. Dubai's infrastructure projects require welding tools that offer consistency and can perform under the region's harsh environmental conditions.

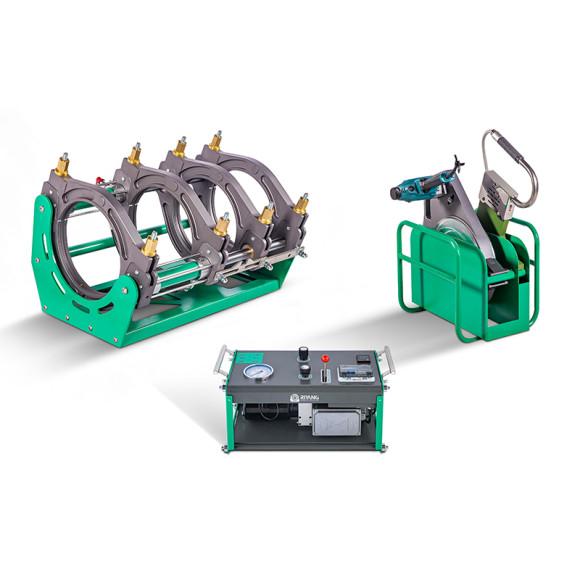

A butt fusion machine consists of several key components: a hydraulic or manual clamp frame to secure the pipes, a trimmer to shave and align pipe ends, a heating plate to melt the contact surfaces, and a pressure control unit to fuse them together. The fusion process must follow strict temperature and pressure guidelines to achieve a joint that is as strong as or stronger than the pipe itself. Machines designed for Dubai's market often include digital controls, real-time monitoring, and rugged frames to handle desert heat and job site challenges.

Why HDPE and Butt Fusion Are Ideal for Dubai Infrastructure

HDPE pipes have become the material of choice for water distribution, drainage systems, gas networks, and cooling applications across Dubai. Their flexibility, resistance to corrosion, and low maintenance requirements make them suitable for the region’s infrastructure goals. Butt fusion welding further enhances these advantages by eliminating joints that rely on mechanical fittings or adhesives.

With no internal beads or crevices, fused HDPE joints maintain the internal diameter of the pipe, reducing flow resistance. This is especially important in large-scale water networks, where energy efficiency and pressure control are key. Moreover, the thermal welding process ensures that each joint becomes a monolithic part of the pipeline, significantly reducing the risk of leaks or failures.

Dubai’s demanding construction environment, with its mix of high humidity, saline groundwater, and intense heat, requires reliable welding technology. A butt fusion machine designed for UAE conditions ensures that joints can endure long service life with minimal degradation.

Core Benefits of Using Butt Fusion Machines

Butt fusion machines bring a range of advantages to infrastructure installations, particularly when working with HDPE systems:

-

Leak-Proof Joints: Properly executed butt fusion welds result in strong, uniform joints that eliminate leakage and infiltration risks.

-

Mechanical Strength: The fused joint can tolerate high internal pressures and external loads, meeting the strength requirements of utility projects.

-

Uniformity and Accuracy: Machines offer controlled temperature and pressure settings, ensuring repeatable weld quality with minimal variation.

-

Long-Term Durability: With no mechanical parts in the joint, there are fewer failure points, reducing maintenance costs over time.

-

Environmental Resistance: HDPE joints resist chemical attack, UV exposure, and corrosion, all common challenges in the Gulf climate.

-

Efficient Operation: Automation and digital controls reduce human error and speed up project timelines, even in complex job environments.

Key Features to Look for in a Butt Fusion Machine

When selecting a butt fusion machine in Dubai, several features should guide the decision-making process:

-

Pipe Diameter Capacity: Machines should accommodate the range of pipe sizes used in your projects, typically from 63mm to over 1200mm.

-

Hydraulic vs. Manual Operation: Hydraulic machines are ideal for large-diameter or high-volume jobs, offering consistent pressure and easier handling.

-

Temperature and Pressure Control: Precision regulators and digital displays help maintain optimal welding parameters, critical for joint integrity.

-

Durability and Mobility: Equipment must be built to endure Dubai’s demanding environments, with protective housings and wheels for easy transport.

-

Data Logging and Traceability: Advanced models can record each weld's parameters, supporting quality control and compliance with industry regulations.

-

Safety Features: Look for systems with automatic shut-off, overheat protection, and emergency release mechanisms to ensure operator safety.

Applications in Dubai's Infrastructure Projects

Butt fusion machines are used across various sectors in Dubai:

-

Water Networks: Municipal water lines rely on fused HDPE pipes to deliver clean water across long distances without leakage.

-

Gas Pipelines: Natural gas systems benefit from the chemical resistance and secure joints provided by butt fusion.

-

Drainage and Sewer Systems: The technique ensures a watertight seal that prevents infiltration and exfiltration in underground networks.

-

District Cooling Systems: With rising demand for sustainable cooling, HDPE systems installed with butt fusion maintain energy efficiency.

-

Irrigation and Agriculture: Durable, UV-resistant joints support water conservation and effective land irrigation.

-

Industrial Installations: Factories and treatment plants use fused HDPE systems to transport chemicals and high-temperature fluids safely.

Trusted Brands and Local Suppliers in Dubai

Dubai hosts a range of local distributors and authorized suppliers offering globally recognized butt fusion machine brands. Some of the most trusted names include:

-

McElroy: Known for high-performance fusion equipment with data logging and automated operation.

-

Riyang: Offers machines designed specifically for the Middle East, balancing performance and affordability.

-

Georg Fischer (GF): Swiss-engineered systems with robust design and international certifications.

-

Widos: German-manufactured machines with advanced temperature regulation and safety features.

-

Franctec Trading: A leading UAE distributor supplying various fusion machines and providing after-sales service, spare parts, and on-site training.

Local access to service, support, and training is a major advantage, reducing downtime and ensuring uninterrupted project workflows.

Maintenance and Operator Best Practices

Maintaining your butt fusion machine is crucial for consistent results and long-term use. Key practices include:

-

Clean Heating Plates Regularly: Contaminants can affect weld quality; clean with a soft cloth before each use.

-

Inspect Pipe Alignment: Misalignment can lead to weak joints; use machine guides and clamps accurately.

-

Monitor Calibration: Ensure temperature and pressure sensors are calibrated for accurate control.

-

Follow Welding Protocols: Adhere to ISO 21307 or DVS standards for fusion pressure, heating time, and cooling duration.

-

Train Operators Properly: Skilled workers ensure better weld quality, reduced waste, and enhanced safety.

-

Schedule Routine Maintenance: Lubricate hydraulic parts, check for wear and tear, and replace worn trimmers or plates as needed.

Conclusion

Dubai's infrastructure boom shows no signs of slowing, and as construction demands rise, so too does the need for efficient, precise welding solutions. Butt fusion machines provide the ideal answer for HDPE piping systems, delivering seamless, high-strength joints that support water, gas, and drainage networks across the region.

Investing in a quality butt fusion machine in Dubai ensures compliance with local regulations, reduces installation errors, and extends pipeline life. With the right machine and well-trained operators, contractors can take on complex projects with confidence, knowing their welded systems will perform reliably for decades. As the city evolves, so must the tools we use to build it—and butt fusion welding remains at the forefront of modern infrastructure development.