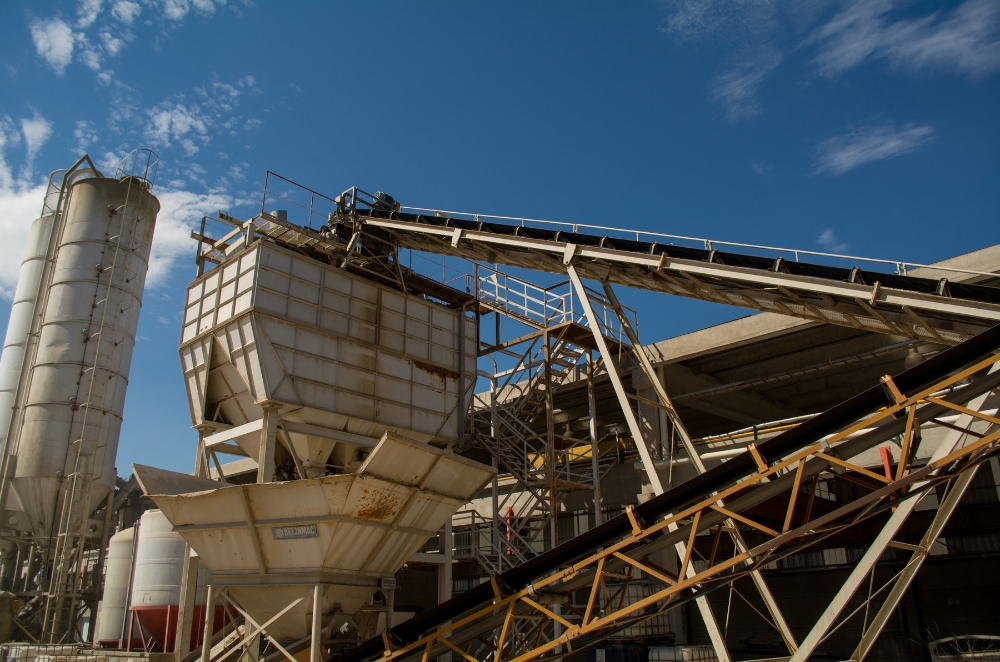

The Evolution of Conveyor Technology

Conveyors have come a long way since the early days. I’ve seen old photos of wooden rollers carrying sacks of grain, and it’s hard to believe how far things have progressed. Now, they’re everywhere—warehouses, factories, airports. I’ve watched a business double its output after swapping out a clunky system for something modern. Even something as straightforward as a roller conveyor belt can make all the difference. It might look like a simple piece of gear, but behind it are decades of design changes meant to save time and protect people’s backs. And when you see them in action, you realise just how much they’ve reshaped the way we work.

From manual hauling to mechanised movement

It used to be all about muscle. People are lugging boxes or pushing carts. Over time, machines took over more of the heavy lifting. You can still see traces of that shift in old warehouses.

-

Hand-cranked rollers did the first jobs

-

Steam engines started moving belts faster

-

Rubber and steel improved strength

-

Motors and controls made everything smoother

These changes weren’t just about speed. They saved workers from injuries that came from hauling loads day after day.

Training staff to get the most out of your system

Even the smartest conveyor won’t work well if no one knows how to use it. I’ve walked into warehouses where the equipment was fine, but staff hadn’t been shown how to adjust settings or spot issues.

-

Short training on controls and safety stops

-

Clear guides for cleaning and upkeep

-

Checklists for daily inspections

-

A point of contact when questions pop up

A little investment in training pays back fast in fewer errors and downtime.

Improving workplace safety through design

I’ve hauled awkward materials myself and felt how quickly your back gets sore. Modern conveyors are set up to prevent that kind of strain. Regulations around manual handling safety have helped shape today’s designs.

-

Heights adjusted so you don’t have to stoop

-

Guards and stops to prevent accidents

-

Sensors that catch jams before they escalate

-

Modular layouts that fit any space

You notice the difference in workplaces that take these details seriously.

Materials and technology shaping modern conveyors

A lot has changed in what conveyors are made of. It’s not all steel anymore. Lighter plastics, better motors, and smart add-ons have become normal.

-

Stainless steel in food factories

-

Plastic belts for lighter items

-

Scales and scanners built right in

-

Speed controls you can tweak as needed

These upgrades make a big impact without demanding a full overhaul.

Automation and smart integration

You don’t have to run a massive operation to use automation. I’ve seen smaller outfits install basic sensors and cut errors overnight. It’s become more accessible for everyone.

-

PLCs set speeds and timing

-

RFID tracks where products go

-

Diagnostics spot small issues early

-

Alerts help you fix problems faster

Automation isn’t about replacing people. It’s about freeing them up for tasks that need attention.

Adapting conveyors to new industries

Conveyors used to just sit in factories. Now they’re nearly everywhere you look. Airports, e-commerce warehouses, recycling plants.

-

Baggage conveyors behind check-in counters

-

Sorters picking orders in online stores

-

Heavy-duty belts carrying scrap metal

-

Clean-room systems for medical supplies

That variety has pushed designers to keep improving.

Environmental considerations and sustainability

I’ve noticed more companies asking about efficiency. Power costs, waste, sustainability—they all matter now. Conveyor makers have had to keep up.

-

Drives that use less energy

-

Recyclable belts that last longer

-

Low-friction parts reduce electricity

-

Easier end-of-life recycling

Small tweaks in design can save a lot of time.

Why robust conveyors matter to Australian businesses

I’ve talked to people who regretted buying the cheapest setup. When a line goes down, it costs more than the savings. Information about robust conveyor systems often highlights how durability and better design can help avoid repeated downtime and unexpected costs.

-

Strong frames that handle constant use

-

Better rollers that run smoother

-

Local support when something breaks

-

Workers trust equipment that doesn’t fail

When you rely on conveyors to keep things moving, quality matters.

Common mistakes when choosing conveyors

I’ve seen plenty of businesses jump in too fast and end up with setups that don’t fit. It’s easy to underestimate details or overestimate what you need. A little caution early on saves headaches.

-

Picking the wrong belt for the product weight

-

Ignoring floor space and workflow patterns

-

Skipping maintenance planning

-

Assuming one size fits every industry

Asking a few extra questions up front can avoid surprises later.

Planning for the future of material handling

Conveyors aren’t done evolving. New tools keep showing up—AI that predicts when a part will fail, sensors that monitor wear in real time. Even smaller businesses are thinking ahead.

-

With modular systems, you can expand later

-

Smarter software that adjusts automatically

-

Budgets set aside for future upgrades

-

Training so staff aren’t left behind

The best time to prepare is before you’re forced to.

Wrapping up: why conveyors keep moving forward

Conveyors have changed a lot, but the core idea is still simple—move stuff from here to there safely and efficiently. What used to be basic wooden rollers has turned into equipment that runs almost on its own. If you’re thinking about upgrading or starting fresh, it helps to know what’s out there and what suits your business best. In the end, a good conveyor isn’t just a tool. It’s a way to make sure work keeps flowing without constant headaches. And sometimes, that peace of mind is the most valuable thing you can invest in.