Chemical Earthing Electrode Manufacturer, Supplier in Delhi

Introduction to Chemical Earthing

In today’s fast-paced, technology-driven world, ensuring electrical safety is paramount. One of the most effective ways to achieve this is through Chemical Earthing. Unlike traditional earthing systems, chemical earthing offers enhanced safety, longevity, and low maintenance—making it the preferred choice across industries.

Whether it’s a high-rise building, an industrial unit, or a commercial establishment, installing a robust and reliable earthing system is essential. And when it comes to quality and performance, choosing the right Chemical Earthing Electrode Manufacturer and Supplier in Delhi makes all the difference.

What is Chemical Earthing?

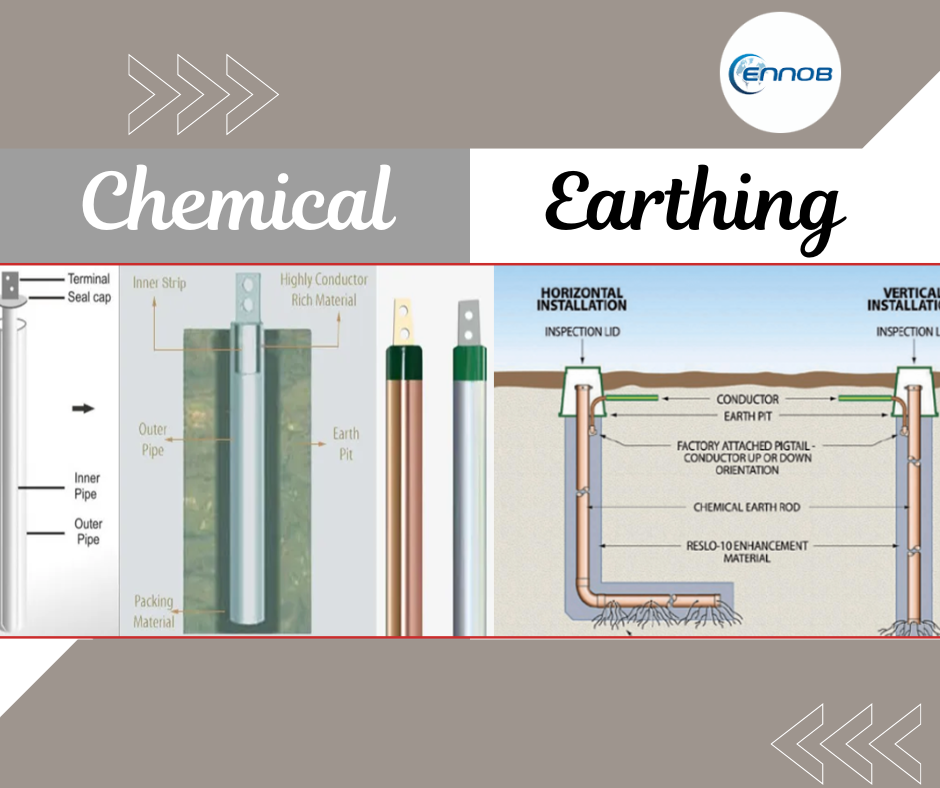

Chemical earthing is a modern earthing technique that uses electrodes filled with a conductive compound (typically a chemical gel or bentonite clay) which retains moisture for extended periods. This helps maintain a low resistance path to the ground, ensuring stable electrical grounding throughout the year.

Unlike conventional earthing methods that may degrade over time due to soil and weather conditions, chemical earthing remains reliable, consistent, and virtually maintenance-free.

Why Chemical Earthing is Crucial for Electrical Safety

Chemical earthing provides a safer and more efficient alternative to traditional earthing systems. Here are some key benefits:

1. Low Resistance Grounding

The chemicals used ensure consistent low earth resistance regardless of soil moisture content or temperature fluctuations.

2. Long Life Expectancy

Chemical earthing electrodes are corrosion-resistant and last longer than conventional GI or copper rods.

3. Maintenance-Free Operation

Once installed, the system requires little to no maintenance, saving time and operational costs.

4. Enhanced Safety

It significantly reduces the risk of electrical shocks, equipment damage, and fire hazards caused by voltage fluctuations or lightning.

Applications of Chemical Earthing

Chemical earthing is suitable for various installations, including:

-

Residential Buildings

-

Telecom Towers

-

Industrial Plants

-

Data Centers

-

Hospitals

-

Power Stations

-

Commercial Complexes

Due to its versatility and dependability, it has become the go-to earthing solution in Delhi and across India.

Choosing the Right Chemical Earthing Electrode Manufacturer in Delhi

With multiple manufacturers and suppliers in the market, selecting a reliable partner for your earthing needs is vital. A trusted Chemical Earthing Electrode Manufacturer in Delhi should offer:

1. High-Quality Materials

Top manufacturers use copper bonded rods, GI electrodes, and highly conductive backfills to ensure optimal performance.

2. Compliance with IS/IEC Standards

Ensure that the products conform to Indian and international safety standards for electrical grounding.

3. Customization and Site-Specific Solutions

Every project is unique. Look for suppliers that offer tailored earthing solutions based on soil resistivity and environmental conditions.

4. Competitive Pricing with After-Sales Support

A good manufacturer doesn’t just sell products—they provide technical support, installation services, and routine inspections if needed.

Top Features to Look for in Chemical Earthing Electrodes

When selecting chemical earthing products, consider the following features:

a. Corrosion Resistance

Electrodes should be coated or treated to resist rust and degradation over time.

b. High Conductivity Compounds

Look for carbon-based compounds or bentonite that retain moisture and conduct electricity efficiently.

c. Maintenance-Free Design

Choose a system that remains effective with minimal watering and upkeep.

d. Long Shelf Life

Products should last at least 10–15 years with consistent performance.

Why Choose a Delhi-Based Manufacturer and Supplier?

Delhi, being a major industrial and commercial hub, houses some of India’s most reputed chemical earthing electrode manufacturers. Here’s why buying locally makes sense:

-

Quick Delivery & Support: Local suppliers can quickly deliver and service your needs.

-

Knowledge of Soil Conditions: Manufacturers in Delhi understand the regional soil resistivity and provide more effective solutions.

-

Customization & Availability: Easy availability of customized products and accessories.

-

On-site Assessment & Installation: Some manufacturers also offer site inspections and turnkey installations.

Related Products Offered by Manufacturers in Delhi

In addition to chemical earthing electrodes, top suppliers often provide:

-

Copper Bonded Earthing Rods

-

Galvanized Iron (GI) Electrodes

-

Backfill Compounds

-

Earthing Strips and Plates

-

Lightning Arresters

-

Earth Pit Covers and Inspection Chambers

These products help complete the earthing system and enhance its overall effectiveness.

Chemical Earthing vs Conventional Earthing

| Feature | Chemical Earthing | Conventional Earthing |

|---|---|---|

| Maintenance | Low to no maintenance | Requires regular watering |

| Lifespan | 10–15 years or more | 3–5 years |

| Earth Resistance Stability | Consistent over time | Varies with season & soil condition |

| Installation Cost | Slightly higher initial cost | Low initial cost |

| Long-Term Value | Higher ROI due to durability | Requires frequent replacement |

As the table shows, chemical earthing offers superior long-term value and safety.

Industries Served by Chemical Earthing Suppliers in Delhi

Reputed manufacturers in Delhi serve a wide array of industries including:

-

Power & Energy

-

Telecommunications

-

IT & Data Centers

-

Manufacturing

-

Healthcare

-

Real Estate

-

Public Infrastructure

This highlights their versatile product offerings and capability to meet complex electrical grounding requirements.

How to Select the Best Chemical Earthing System for Your Needs

Here’s a simple checklist to help you choose the best earthing solution:

-

Conduct a Soil Resistivity Test

-

Consult with a Reputed Manufacturer or Supplier

-

Choose Electrodes Based on Site Conditions

-

Consider Long-Term Maintenance Costs

-

Ensure Compliance with Safety Norms

With these steps, you can ensure a safe, efficient, and compliant grounding system for your premises.

Benefits of Partnering with a Local Supplier in Delhi

1. Faster Turnaround Time

Get your products delivered and installed more quickly compared to distant suppliers.

2. Better Coordination

A local supplier can visit your site, understand challenges firsthand, and provide optimal solutions.

3. Cost Efficiency

Save on transportation costs and avail competitive pricing with Delhi-based chemical earthing suppliers.

4. Technical Assistance

Receive on-call support and annual inspection services to maintain system performance.

Conclusion: Invest in Quality Chemical Earthing for Safety and Reliability

In conclusion, chemical earthing is an indispensable part of any safe electrical infrastructure. Whether you’re managing a residential project or an industrial setup, investing in a high-quality earthing system ensures protection against electrical faults, voltage surges, and fire hazards.

Choosing a reputed Chemical Earthing Electrode Manufacturer and Supplier in Delhi not only gives you access to superior products but also technical expertise and post-installation support. Delhi-based suppliers bring unmatched industry knowledge, faster delivery, and competitive pricing to the table.

Don’t compromise on safety—opt for reliable, maintenance-free, and long-lasting chemical earthing solutions today.

FAQs About Chemical Earthing in Delhi

Q1. What is the lifespan of a chemical earthing system?

A: A well-installed chemical earthing system can last up to 15 years or more with minimal maintenance.

Q2. Is chemical earthing suitable for all soil types?

A: Yes, chemical earthing is designed to perform efficiently in various soil conditions, including dry and rocky terrains.

Q3. Can I install chemical earthing myself?

A: While it's possible, it is highly recommended to consult professional installers for optimum safety and compliance.

Q4. What are the best materials used in chemical earthing electrodes?

A: Copper-bonded rods and galvanized iron (GI) rods filled with conductive compounds like bentonite or carbon-based gels are commonly used.