CNC Machining for Telecommunications: Enabling Next-Gen Connectivity with Precision

In today's hyperconnected world, where 5G rollouts, satellite communications, and high-speed data infrastructures are reshaping global industries, the demand for durable, high-precision telecom components is greater than ever. From antenna mounts in rural broadband networks to microwave housings in defense communications, manufacturers must meet exacting standards for reliability and performance. To deliver on these expectations, many engineers and procurement teams rely on cnc machining for telecommunications as a proven solution to achieve complex geometries, tight tolerances, and fast production cycles without compromising quality.

Why CNC Machining Matters in the Telecommunications Industry

The telecommunications sector is built on precision. Every connector, housing, or RF shielding component must function flawlessly in mission-critical environments—whether deep underground, on a cellular tower, or orbiting the Earth. As network infrastructure advances, components are shrinking in size while increasing in complexity, often requiring multi-axis machining and advanced material compatibility.

CNC machining plays a vital role in delivering components with exceptional surface finishes, strict tolerance control (±0.001”), and consistent part replication. Whether it's machining aluminum for lightweight enclosures or stainless steel for weather-resistant outdoor terminals, CNC technology ensures components meet telecom-specific mechanical and electrical requirements.

Technical Considerations in CNC Machining for Telecommunications

Key Components and Use Cases

CNC machining is instrumental in producing a wide array of telecom components including:

-

RF enclosures and waveguide housings

-

Heat sinks and thermal interface parts

-

Mounting brackets and support frames

-

Antenna and satellite communication parts

-

Shielded compartments for sensitive electronics

These parts often require specialized finishing, such as anodizing or EMI/RFI coatings, to enhance durability and performance under extreme environmental conditions.

Material Selection for Telecom Applications

Material choice directly impacts signal clarity, corrosion resistance, and overall reliability in the field. CNC machining supports a broad spectrum of metals and plastics such as:

-

Aluminum: Preferred for lightweight, corrosion-resistant applications like antenna casings

-

Copper: Ideal for electrical components and EMI shielding

-

Stainless Steel: Offers strength and weather resistance for outdoor enclosures

-

PTFE and PEEK: Non-metallic options for insulation and signal-sensitive parts

Telecommunications often require machining materials that balance conductivity, structural integrity, and weight—all achievable through CNC’s high repeatability.

Tolerance Standards and Quality Requirements

In telecom, even a minor dimensional deviation can result in signal loss, overheating, or poor connectivity. CNC machines allow for ultra-precise tolerances down to ±0.001 inches or finer, ensuring critical fits for mating components and consistent signal pathways. Surface finishes are equally important, particularly for RF applications, where smoother surfaces can reduce signal distortion and improve thermal transfer.

Advanced quality control, such as coordinate measuring machines (CMM) and digital inspection, guarantees that parts meet telecom industry requirements across high volumes.

Choosing the Right CNC Machining Partner for Telecommunications

Selecting the right manufacturing partner is crucial to achieving high-performance results in telecom applications. Key attributes to consider include:

-

Industry Certifications: ISO 9001 and other quality management systems ensure process control and traceability

-

Material Handling Expertise: Understanding how to machine and finish telecom-approved alloys and plastics

-

Advanced Equipment: Multi-axis CNC machines, tight-tolerance metrology tools, and custom fixturing capabilities

-

Rapid Prototyping to Production: Ability to scale from small prototype runs to full-volume production without delays

MYT Machining is uniquely positioned to support telecommunications clients across all phases of product development. With years of experience machining complex components for high-frequency and rugged field-use environments, our team provides turnkey CNC solutions tailored to industry specifications. From prototype validation to high-volume delivery, MYT ensures consistent accuracy, tight quality control, and rapid lead times.

Final Thoughts: Why Precision Matters in Telecom Manufacturing

As telecommunications evolve—from fiber optics to 6G and IoT ecosystems—the need for precision-engineered components will only intensify. By choosing a CNC machining partner that understands the material, performance, and tolerance demands of the sector, OEMs and engineers can minimize failure risk, reduce downtime, and gain competitive agility in a rapidly changing market.

Whether you're building critical RF assemblies or structural mounts for satellite systems, CNC machining offers the precision and adaptability needed to meet modern telecom challenges. MYT Machining invites telecom innovators to explore how advanced CNC solutions can power the next generation of global connectivity.

Categorii

Citeste mai mult

Dreams are like secret messages from our subconscious mind. Sometimes they make us smile, sometimes they scare us, and sometimes they leave us wondering, “What was that all about?” One of the most common dreams people experience is marriage. But what does sapne mein shadi dekhna actually mean? Is it a sign of something good coming your way, or is your mind simply reflecting...

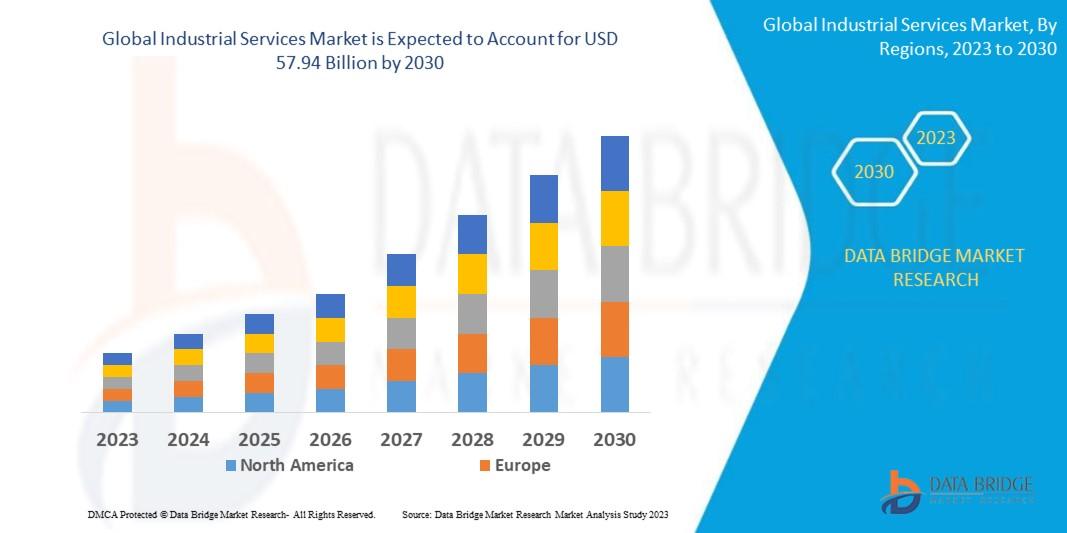

"Global Demand Outlook for Executive Summary Industrial Services Market Size and Share The global industrial services market size was valued at USD 41.78 billion in 2024 and is projected to reach USD 64.61 billion by 2032, with a CAGR of 5.60% during the forecast period of 2025 to 2032. This Industrial Services Market report includes a wide-ranging evaluation of the market’s growth...

When it comes to modern cleaning technologies, the laser cleaner gun has become a game-changer. Traditional methods like chemical cleaning, abrasive blasting, or manual scrubbing often leave residues, damage surfaces, or require downtime. Mart Laser brings a reliable solution to industries seeking efficiency and precision through its advanced laser cleaner guns, designed to meet the demands of...

Minimalist mobile cover designs are crafted to appeal to users who value simplicity, elegance, and subtlety in their accessories. For many people, a bulky or overly decorative mobile back cover takes away from the clean look of their device. A slim iPhone 15 back cover provides essential protection while maintaining the sleek appearance of the phone itself. A thoughtfully designed iPhone 15...

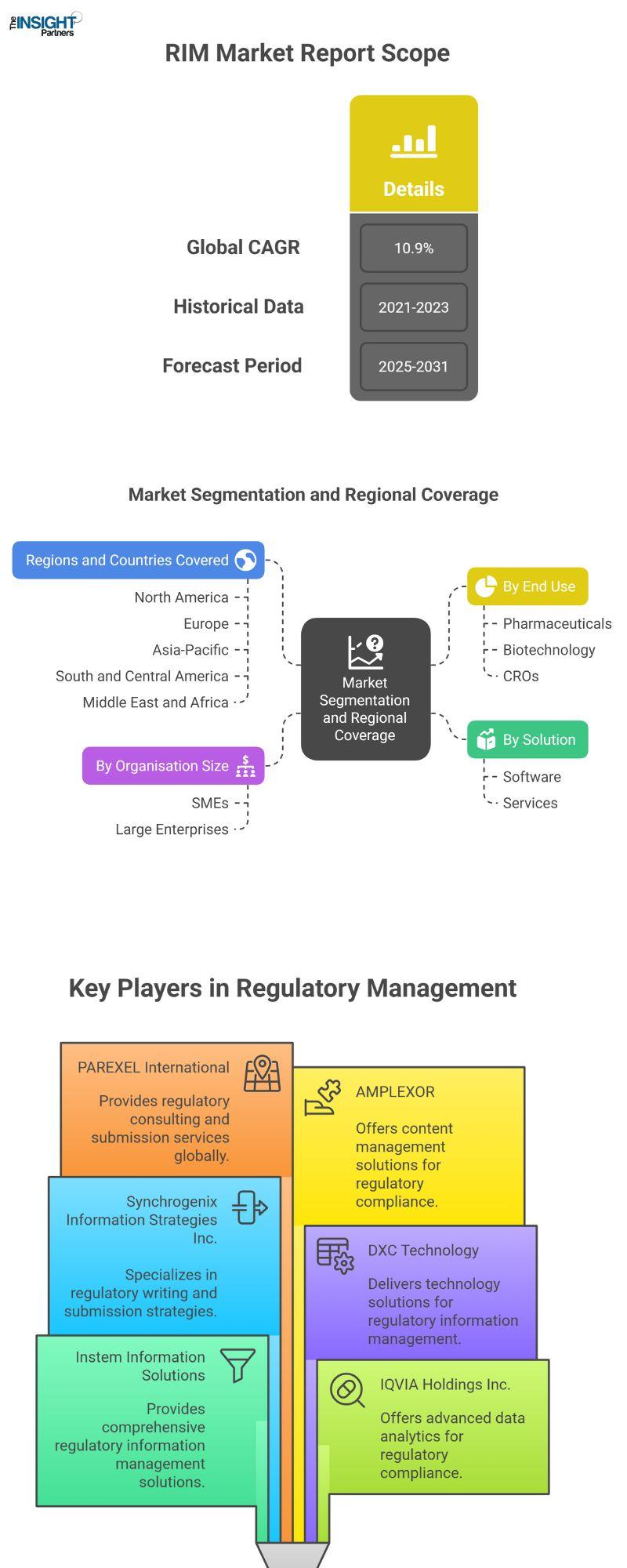

United States of America – August 21, 2025 – The Insight Partners has announced the publication of its novel research report, "Regulatory Information Management Market: A Detailed Analysis of the Global Market." The report provides a complete snapshot of the market, including its past performance, recent trends, and future growth opportunities until 2025 to 2031. While the market is...