Maximizing Product Success with Expert Prototype Molding Services

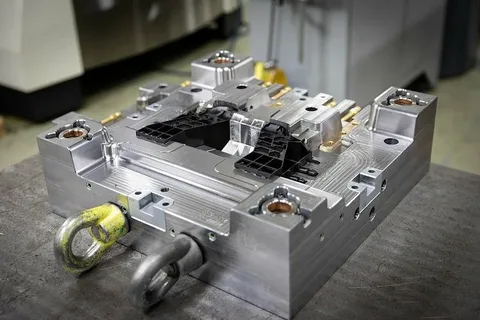

Bringing a new product to market involves numerous steps, from ideation to manufacturing. One of the most crucial phases in this journey is prototyping, where designers and engineers test and refine their ideas before full-scale production. Prototype molding services play a key role in this process, enabling rapid, cost-effective development of functional product models. These services not only help validate design concepts but also ensure products meet market expectations and regulatory standards.

With the rapid pace of innovation, businesses cannot afford costly errors or long development cycles. Leveraging expert prototype molding services significantly reduces risks by providing tangible feedback early in the process. Whether you're developing a medical device, consumer gadget, or automotive component, the right prototyping partner can help turn your idea into a market-ready product with confidence and precision.

The Critical Role of Prototypes in Product Development

Prototypes serve as the blueprint for future success. They allow designers and engineers to test product concepts, functionality, and user interaction before committing to large-scale manufacturing. Without prototypes, companies risk bringing flawed products to market, which can result in costly recalls, negative customer reviews, and diminished brand trust. By investing in prototype molding services, businesses gain the ability to explore alternative designs, assess performance, and refine usability through tangible feedback.

Beyond functionality, prototypes are instrumental in communicating ideas to stakeholders, including investors, partners, and customers. A visual, touchable model often conveys a concept more effectively than drawings or digital models. Expert prototype molding services ensure these prototypes are manufactured with precision and durability, representing the true potential of the final product. This not only accelerates decision-making but also builds confidence across the product development team.

Benefits of Partnering with Expert Prototype Molding Services

Choosing a specialized provider of prototype molding services can offer a range of advantages, particularly in terms of quality, speed, and technical know-how. These experts bring a wealth of experience to the table, often gained through working across multiple industries and handling complex projects. Their ability to recommend the right materials, molding techniques, and design improvements can result in better performance and lower production costs. Furthermore, their insights can prevent common mistakes that derail product development.

Time-to-market is another critical factor in modern product development, and expert prototype molding services help reduce development cycles significantly. With in-house tools like CNC machining, 3D printing, and injection molding, experienced providers can turn around functional prototypes in a matter of days rather than weeks. This agility enables multiple iterations of testing and improvement, ensuring that the final product is both innovative and reliable. Ultimately, a trusted prototype partner becomes a strategic extension of your R&D team.

Enhancing Design Iteration and Risk Reduction

Iterative design is a fundamental aspect of successful product development, and prototype molding services enable this process by providing fast, accurate models for each stage. Rather than relying solely on digital simulations or conceptual drawings, teams can interact with real, physical versions of their products. This allows for thorough testing in real-world scenarios, uncovering potential flaws that might go unnoticed in a virtual environment. By catching and correcting these issues early, companies can avoid costly redesigns later in the production pipeline.

Prototyping also plays a critical role in risk mitigation, especially in highly regulated industries like healthcare, aerospace, or automotive. Expert prototype molding services ensure compliance with industry standards through rigorous quality control, material certification, and precise documentation. As a result, prototypes are more than just test models—they’re reliable indicators of how the final product will perform under stress, temperature variations, or user conditions. This predictive capability helps secure regulatory approvals and gain stakeholder trust more quickly.

Customization and Material Flexibility in Prototype Molding

Modern prototype molding services offer unparalleled flexibility in material selection and customization options. Whether the product requires lightweight polymers, impact-resistant thermoplastics, or heat-tolerant composites, expert providers can recommend the best fit based on intended use, budget, and performance criteria. This material versatility allows designers to explore multiple configurations before locking in the final design, improving both product functionality and cost-efficiency.

Customization goes beyond materials; advanced molding services also allow for variations in texture, color, and structural complexity. Whether the goal is to test different ergonomic features or simulate how a final product will look on the shelf, prototype molding providers can produce parts that closely mimic the production version. This realistic representation is essential for user testing, marketing presentations, and investor pitches. Thanks to these tailored solutions, businesses can ensure every detail aligns with the brand's goals and customer expectations.

Choosing the Right Prototype Molding Partner for Long-Term Success

Selecting the right provider of prototype molding services is crucial to ensuring product success. Beyond technical capabilities, a good partner should demonstrate excellent communication, project management, and a deep understanding of your industry. Look for providers that offer a collaborative approach—one where engineers and designers work hand-in-hand with your team to bring the vision to life. Transparency in timelines, cost, and deliverables is equally important to maintaining trust and staying on schedule.

It’s also wise to consider the scalability of the services offered. Some prototyping firms offer bridge tooling or low-volume production alongside their prototyping capabilities, allowing for a seamless transition from concept to market. Working with such partners means you don’t have to switch vendors mid-stream, reducing the risk of delays or quality inconsistencies. By aligning with expert prototype molding services early in your product lifecycle, you position your business for long-term innovation, customer satisfaction, and competitive advantage.

Conclusion

In today’s competitive market, bringing a successful product to life requires more than a great idea—it demands meticulous testing, rapid iteration, and smart material choices. Prototype molding services provide the tools and expertise needed to navigate this journey efficiently. From improving product design and reducing risk to accelerating time-to-market and ensuring long-term reliability, these services are essential for any company committed to innovation and excellence.