Injection Molding Services: Key Features and Cost Factors

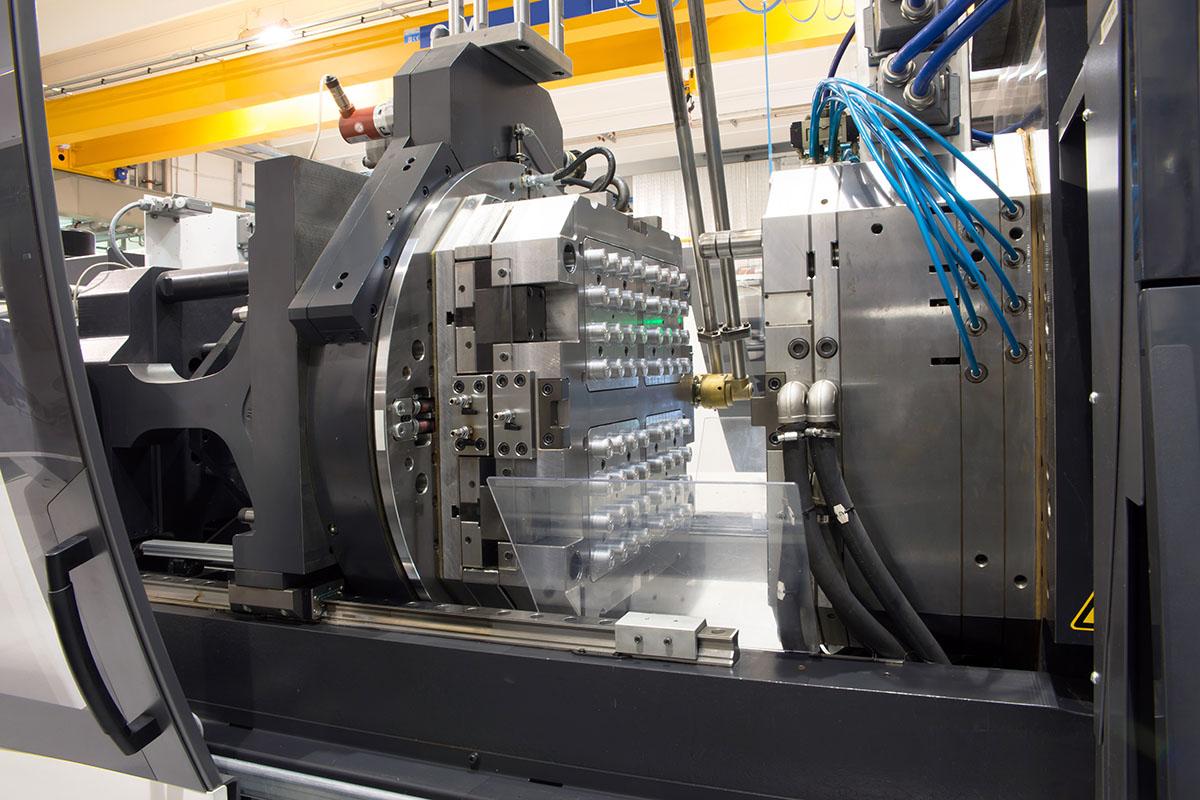

Injection molding is one of the most widely used manufacturing processes for producing high-quality plastic parts in large volumes. It involves injecting molten material into a mold cavity, where it cools and solidifies into the desired shape. This process is highly efficient and can produce components with precise dimensions and excellent surface finishes, making it ideal for various industries such as automotive, electronics, healthcare, and consumer products.

Understanding Injection Molding Services

When businesses choose Injection Molding Services , they are opting for a process that offers repeatability, accuracy, and cost efficiency. Service providers typically manage the complete production cycle, from initial mold design and material selection to production and quality inspection. Advanced machinery and technology ensure that even complex geometries and tight tolerances are achievable. The flexibility of the process allows manufacturers to create parts in different sizes, colors, and material compositions, meeting diverse product requirements.

Key Features of Injection Molding

One of the most notable features of injection molding is its high precision. The molds are engineered with extreme accuracy, ensuring that each part is identical to the design specifications. This consistency is particularly important for industries where dimensional accuracy directly impacts product performance. Another feature is the ability to use a wide range of materials, including various thermoplastics, thermosets, and elastomers, allowing manufacturers to meet specific performance needs.

The process is also highly scalable. Once a mold is created, it can be used to produce thousands or even millions of parts without losing quality. Additionally, modern injection molding machines incorporate automation, which not only speeds up production but also minimizes human error. Automation can include robotic part removal, automated inspection, and efficient cycle time management.

Cost Factors in Injection Molding

The cost of injection molding depends on several critical factors, with mold creation being one of the largest upfront investments. Mold complexity, size, and material all influence the cost. Simple molds with fewer features are generally less expensive, while complex molds with intricate details require more time and precision to manufacture.

Material choice is another significant factor. High-performance materials with special properties, such as heat resistance or impact strength, tend to be more expensive than standard plastics. Additionally, the volume of production affects the overall cost. Large production runs often reduce the per-unit cost due to economies of scale, whereas small runs may result in a higher per-part price.

Cycle time also plays a role in cost calculation. Shorter cycle times mean more parts can be produced in a given period, reducing labor and operational expenses. However, achieving faster cycle times requires efficient mold design, appropriate material selection, and advanced machine capabilities.

Balancing Quality and Budget

Businesses must strike the right balance between quality requirements and budget constraints. While it may be tempting to cut costs by using lower-grade materials or simpler molds, this can lead to issues such as part defects, reduced durability, or performance failures. A reputable injection molding provider will work closely with clients to recommend the most suitable materials and design adjustments that meet both quality standards and cost objectives.

Investing in a well-made mold can also lead to long-term savings, as it can be used repeatedly without compromising part quality. Moreover, incorporating design for manufacturability (DFM) principles early in the development stage can help minimize costly revisions later.

Conclusion

Injection molding remains a preferred choice for mass-producing high-quality plastic components due to its precision, efficiency, and versatility. Understanding the key features and cost factors involved allows businesses to make informed decisions when selecting a service provider. By working with experienced professionals and carefully considering production needs, companies can achieve optimal results that meet both performance expectations and financial goals.