Automated Conveyor Systems Boosting Warehouse Productivity with Smart Solutions

Automated conveyor systems are gaining traction due to their ability to streamline manufacturing and logistics processes. By integrating sensors, robotic controls, and intelligent software, automated conveyors enhance accuracy, reduce errors, and optimize resource utilization across industries.

An overhead conveyor system is a type of material handling equipment that uses a suspended track to move items from one point to another. Unlike floor conveyors, these systems are mounted above the ground, saving valuable floor space and enhancing the workflow within manufacturing and storage facilities. Overhead conveyors are versatile and can transport items of varying shapes, sizes, and weights, making them suitable for industries such as automotive, electronics, food and beverage, and e-commerce.

These systems can operate continuously, ensuring a smooth and uninterrupted flow of materials, which is particularly important for large-scale production lines. The adaptability of overhead conveyors allows manufacturers to configure layouts based on specific operational requirements, including curves, inclines, and vertical lifts, making them a flexible solution for complex facility designs.

Market Dynamics Driving Growth

The Overhead Conveyor Systems Market has been experiencing steady growth due to several key factors. Increasing automation across industries has created a significant demand for advanced material handling solutions that can streamline processes and minimize human intervention. Companies are actively seeking ways to reduce operational costs while enhancing productivity, and overhead conveyor systems provide an efficient solution to these challenges.

Additionally, the expansion of e-commerce and the growing need for rapid order fulfillment have further fueled the demand for efficient conveyor solutions. Warehouses and distribution centers are investing heavily in overhead conveyor systems to improve storage capacity, reduce manual handling, and speed up product movement. For more detailed insights into market trends and forecasts, you can explore the Overhead Conveyor Systems Market report.

Types of Overhead Conveyor Systems

Overhead conveyor systems come in various types, each designed to meet specific operational needs. The most common types include:

-

Monorail Conveyors: These consist of a single track and are ideal for transporting small to medium-sized items. They are widely used in automotive assembly lines and paint shops.

-

Trolley or Carrier Systems: These systems use trolleys suspended from the track to transport items. They are suitable for heavy loads and can navigate complex layouts with curves and inclines.

-

Power and Free Conveyors: These offer dual-track systems where powered and non-powered sections allow for accumulation and sorting of products, making them suitable for high-volume distribution centers.

-

Overhead Chain Conveyors: Commonly used in manufacturing plants, these systems employ chains to move products along a track, providing reliable handling for heavy or irregularly shaped items.

Each type has unique advantages, and the selection depends on factors such as load weight, production speed, facility layout, and integration with other automated systems.

Key Industry Applications

The versatility of overhead conveyor systems has made them integral to a wide range of industries. In the automotive sector, these conveyors streamline the movement of parts and assemblies, reducing production time and minimizing bottlenecks. Automotive plants often require precise positioning of components along complex assembly lines, and overhead conveyors provide an efficient and reliable solution.

In the food and beverage industry, overhead conveyors ensure hygienic and contamination-free transport of goods. They can be equipped with stainless steel tracks and easy-to-clean trolleys, meeting strict sanitation standards. Similarly, in warehousing and logistics, these systems enhance storage utilization by freeing up floor space and enabling faster sorting and distribution of goods.

The e-commerce sector has also benefitted significantly from overhead conveyor systems. With the surge in online shopping, the need for rapid order processing and efficient warehouse operations has driven adoption of advanced conveyor solutions. These systems reduce manual handling, increase throughput, and ensure timely delivery, which is critical in today’s competitive market.

Technological Advancements

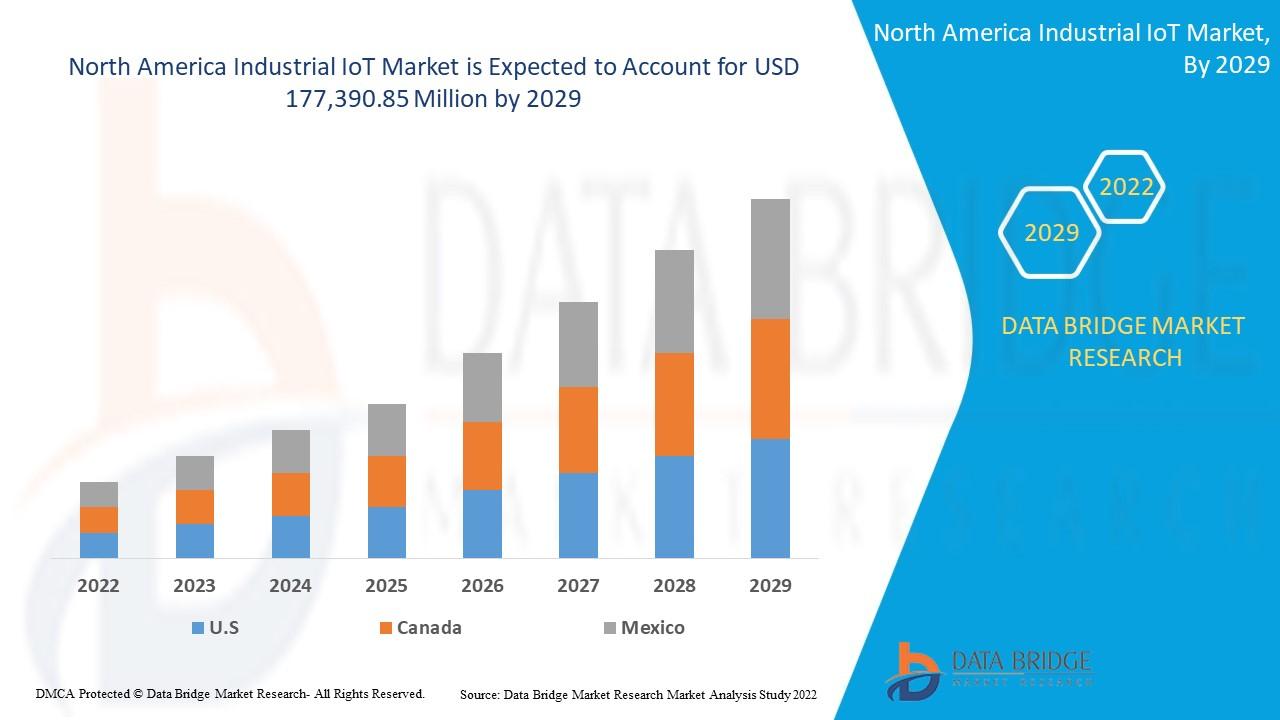

Modern overhead conveyor systems are integrating advanced technologies to boost performance and operational efficiency. Smart sensors, automated controls, and IoT connectivity allow real-time monitoring of conveyor operations, reducing downtime and enabling predictive maintenance. Furthermore, automation software can optimize routing, load balancing, and tracking of products throughout the production or distribution process.

Energy efficiency is another area of focus. Newer conveyor systems are designed to consume less power while maintaining high performance, aligning with the sustainability goals of many industries. Additionally, modular conveyor designs allow businesses to expand or modify their systems without major infrastructure changes, providing long-term scalability.

Challenges and Opportunities

Despite the growth prospects, the overhead conveyor systems market faces certain challenges. High initial investment costs, system complexity, and the need for skilled personnel for installation and maintenance can hinder adoption, particularly among small and medium-sized enterprises. Additionally, integration with existing facility layouts can be challenging in older plants.

However, these challenges also present opportunities. As technology advances, manufacturers are introducing cost-effective, modular, and easy-to-install systems that lower entry barriers. Increasing awareness about operational efficiency, labor cost reduction, and workplace safety is expected to further drive market adoption.

Future Outlook

The future of the overhead conveyor systems market looks promising, driven by continuous innovations in automation and material handling solutions. Industries are increasingly moving towards smart factories, where interconnected conveyor systems, robots, and AI-driven management software work in synergy. This trend will create opportunities for conveyor system providers to deliver integrated, intelligent solutions tailored to diverse industrial needs.

As the global manufacturing landscape evolves, overhead conveyor systems will remain a cornerstone of efficient operations. Their ability to enhance productivity, optimize space, and support automation makes them an indispensable investment for businesses aiming to stay competitive in the fast-paced industrial environment.