The Role of Energy Valves in Modern Industrial Systems

The Role of Energy Valves in Modern Industrial Systems

Introduction to Energy Valves

What is an energy valve?

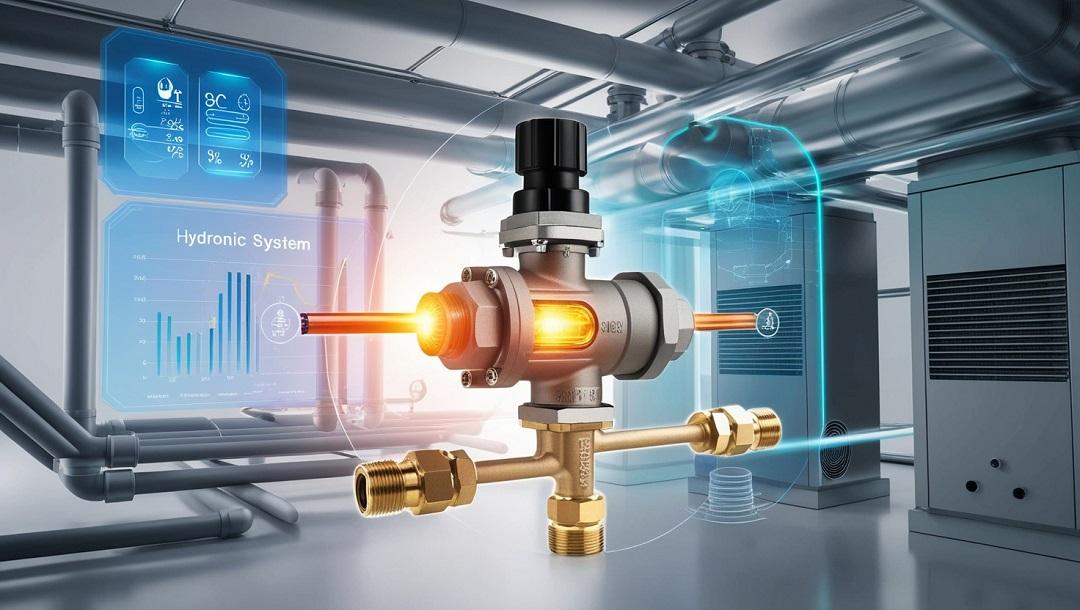

An energy valve is a pressure-independent control valve equipped with smart technology that regulates and monitors thermal energy transfer in hydronic systems. Unlike conventional valves, energy valves do more than modulate flow—they provide real-time data on temperature differentials, flow rates, and energy consumption. These insights allow system operators to make informed decisions, optimise performance, and identify inefficiencies before they escalate into larger issues.

Functionally, an energy valve combines multiple components into a single, intelligent unit. Typically, it integrates a two-way control valve, flow meter, temperature sensors, and a controller with communication capabilities. This compact but powerful design ensures precise control while also reducing the need for multiple separate components within the pipework.

Brief history of energy valves in HVAC and industrial sectors

The demand for energy efficiency in commercial and industrial environments has steadily increased since the early 2000s, driven by stricter regulations, rising utility costs, and the push towards decarbonisation. The energy valve was introduced as a response to these pressures, providing a solution that combined mechanical control with digital monitoring.

Initially adopted in high-spec commercial buildings and complex HVAC systems, energy valves soon gained popularity across broader industrial applications. The ability to integrate them directly into Building Management Systems (BMS) made them attractive to engineers seeking more granular control over system performance. As IoT capabilities improved, so did the intelligence and reliability of energy valves—positioning them as essential components in any modern hydronic infrastructure.

How Energy Valves Work

Core components and functionality

At the heart of every energy valve lies the ability to monitor and control the transfer of thermal energy. This is accomplished through a combination of internal sensors and actuators that measure and respond to real-time changes in flow rate, supply and return temperatures, and differential pressure. A built-in algorithm calculates energy consumption and adjusts valve positioning accordingly.

The key components include:

● A pressure-independent control body that maintains constant flow despite pressure fluctuations.

● Temperature sensors located on the supply and return sides.

● An ultrasonic or magnetic flow meter for accurate flow readings.

● A smart actuator that communicates with external systems via BACnet, Modbus, or similar protocols.

This configuration ensures not only accurate control but also the ability to collect operational data that supports ongoing optimisation. In some designs, additional features such as glycol monitoring, ΔT management, or cloud-based analytics are included to further refine system operation.

Integration with Building Management Systems (BMS)

One of the most significant advantages of energy valves is their compatibility with BMS platforms. This integration allows facilities teams to visualise performance data, receive alerts, and adjust system settings remotely. For larger installations, this level of control provides immense value by reducing the need for manual interventions and enabling proactive maintenance strategies.

Communication protocols such as BACnet/IP or Modbus TCP/IP allow for seamless connectivity, ensuring that the energy valve acts not just as a mechanical device, but as an intelligent data node. Engineers can review historical trends, benchmark performance across multiple assets, and apply corrective measures without disrupting system operation.

Energy metering and performance monitoring

Beyond flow regulation, the embedded sensors in an energy valve collect detailed performance data. This information includes real-time flow rates, energy consumption in kilowatt-hours, ΔT values, and fluid temperature. By making this data available at the BMS level, energy valves help identify issues like underperforming coils, poorly balanced loops, or low ΔT syndrome.

With automated reporting features, stakeholders can track usage patterns, compare energy efficiency across different zones or units, and verify the results of optimisation efforts. This makes the energy valve an invaluable tool not only for engineers during commissioning, but also for building owners and operators aiming to track ROI on energy-saving initiatives.

Benefits of Energy Valves in Industrial Applications

Improved energy efficiency

One of the primary reasons energy valves have become a standard in modern industrial systems is their contribution to improved energy efficiency. Traditional systems often rely on static balancing and manual adjustments, which can lead to inconsistent flow, wasted energy, and uneven thermal distribution. By contrast, energy valves dynamically adjust flow based on real-time demand, ensuring optimal heat transfer and preventing over-pumping.

This active management not only reduces overall energy consumption but also helps maintain more consistent indoor climates. In environments with variable occupancy or fluctuating production schedules, the energy valve responds in real time, eliminating inefficiencies that traditional systems fail to address. This kind of control is particularly valuable in multi-zone installations, where each area may have vastly different thermal requirements.

Reduced operational costs

Integrating energy valves into an industrial system can significantly cut operational costs. Beyond energy savings, these valves contribute to longer equipment life and lower maintenance expenditure. Because the valve ensures proper ΔT across coils and avoids over-delivery of flow, pumps and chillers operate within their optimal ranges, experiencing less mechanical stress.

In addition, the diagnostic data provided by energy valves enables quicker fault detection and more targeted troubleshooting. This reduces downtime and the number of site visits required, especially in geographically dispersed facilities. Over time, the cumulative savings from efficiency gains and reduced servicing build a compelling case for investment in energy valves.

Streamlined commissioning and balancing

Commissioning a hydronic system can be time-consuming and prone to errors, particularly in large-scale or complex industrial settings. Energy valves eliminate much of the guesswork involved in manual balancing. Their built-in sensors automatically regulate flow according to setpoints, ensuring correct distribution without the need for manual intervention at each terminal unit.

This streamlining not only accelerates project timelines but also ensures systems start performing at peak efficiency from day one. In refurbishment projects or system upgrades, where legacy components may complicate balancing, the self-regulating behaviour of energy valves simplifies integration and reduces commissioning risks.

Enhanced system control and diagnostics

A major advantage of energy valves is their role in system diagnostics. Engineers and maintenance teams gain continuous access to operational data, allowing them to monitor performance in real time and adjust system parameters remotely. This reduces dependency on reactive maintenance and supports more predictive strategies.

The granular data also enables more accurate energy reporting, supporting compliance with environmental regulations and helping facility managers validate performance claims. Over time, this builds a knowledge base that can inform future system designs and upgrades, enhancing the long-term reliability of the infrastructure.

Key Use Cases and System Applications

District heating and cooling systems

District energy systems supply heating or cooling from a central plant to multiple buildings or facilities via a network of insulated pipes. These systems benefit greatly from energy valves, which help regulate thermal transfer at the end user level. By monitoring ΔT and flow, energy valves prevent individual units from drawing excessive flow, protecting the network's overall balance and efficiency.

In seasonal transitions, where loads fluctuate dramatically, energy valves maintain stable system performance without requiring manual recalibration. Their intelligence enables smoother operation across the district loop, particularly in mixed-use developments where demand varies widely between residential, commercial, and industrial zones.

Commercial HVAC networks

In commercial HVAC applications, energy valves improve indoor climate control while reducing energy bills. Office buildings, hospitals, and schools often operate under strict comfort parameters, requiring consistent thermal delivery despite changing occupancy patterns. Energy valves adapt to these changes automatically, optimising coil performance and keeping ΔT within design parameters.

This results in better comfort outcomes for occupants, less strain on chillers and boilers, and fewer complaints or service calls related to uneven heating or cooling. Additionally, the ability to capture and analyse performance data enables facilities teams to fine-tune operations without invasive retrofits or manual rebalancing.

High-demand manufacturing facilities

Industrial manufacturing environments often involve high thermal loads, especially in processes requiring heating or cooling of equipment, materials, or spaces. Here, energy valves serve a dual function: maintaining process stability and improving plant efficiency. By ensuring flow is only delivered where needed, they minimise waste and support more precise temperature control.

In facilities operating around the clock, where energy use is substantial, even marginal improvements in efficiency can translate into large cost savings. Moreover, data from energy valves supports internal energy audits, making them a useful tool for companies aiming to meet sustainability targets or comply with carbon reporting standards.

Comparison: Energy Valves vs Traditional Control Valves

Efficiency

Traditional control valves typically rely on differential pressure to regulate flow, which often results in imbalances across the system. As pressure varies throughout the network, these valves may deliver too much or too little flow, reducing overall efficiency. Energy valves, on the other hand, maintain pressure independence. This ensures the correct flow is consistently delivered, regardless of fluctuations elsewhere in the system.

The result is not only improved energy distribution, but also more stable thermal conditions and less strain on pumps and chillers. By actively managing ΔT, energy valves ensure that energy is used effectively rather than being wasted through over-circulation. Over time, this contributes to significantly lower operating costs and a reduced carbon footprint.

Installation and commissioning complexity

Installing traditional valves often involves multiple components: a control valve, a balancing valve, temperature sensors, and sometimes external metering equipment. Each requires careful setup and calibration. In contrast, energy valves integrate all these functions into one unit, simplifying installation and reducing the likelihood of setup errors.

From a commissioning perspective, energy valves significantly streamline the process. Traditional systems demand manual balancing at every terminal unit, a time-consuming task that’s prone to error. Energy valves self-regulate based on digital parameters, which means system optimisation can happen much faster, even in large or complex networks.

Data visibility and system intelligence

Perhaps the most significant difference lies in data access. Traditional valves offer little to no performance feedback unless paired with separate metering equipment. Even then, data must often be collected manually. Energy valves, in contrast, continuously collect and transmit detailed information about flow, temperature, energy usage, and valve position.

This real-time data enables facility managers to make informed decisions, detect faults early, and optimise performance without disrupting operations. It also supports advanced strategies such as demand-based control, predictive maintenance, and performance benchmarking—capabilities that conventional valves cannot provide without significant retrofitting.

Role of PIC Valves in Complementary System Design

What is a PIC valve?

A Pressure Independent Control (PIC) valve is a mechanical valve that ensures constant flow regardless of system pressure variations. It combines a differential pressure regulator and a control valve into one compact unit. Unlike traditional balancing valves, a PIC valve automatically adjusts to maintain design flow, improving consistency and reducing the need for manual intervention.

PIC valves are particularly useful in applications where load conditions fluctuate and consistent thermal delivery is critical. By ensuring a stable flow rate, they help avoid overheating or underheating across circuits, particularly in systems with long or complex pipe runs.

How PIC valves support energy valve functionality

While energy valves provide advanced monitoring and control, PIC valves serve as essential complements in broader system design. In large-scale or multi-zone installations, PIC valves can be used at terminal units or branch circuits to maintain stable flow rates, supporting the overall balance maintained by the central energy valve.

This layered approach to control—using energy valves for intelligence and PIC valves for precision at the point of delivery—ensures optimal performance across the network. It reduces system instability caused by pressure fluctuations and enhances overall energy efficiency. When used together, both valve types enable a scalable, reliable control strategy that can adapt to varying loads and building uses.

Future Trends in Valve Technology

Smart system integration

Valve technology is advancing rapidly, with smart integration now playing a central role in system design. Energy valves have become increasingly compatible with building automation platforms, enabling more granular control over energy delivery. Through open communication protocols, these valves act as data points within a larger digital ecosystem, supporting centralised control, remote configuration, and performance tracking.

In newer buildings, energy valves are often installed as part of a broader smart infrastructure from the outset. In older facilities, they’re retrofitted to replace conventional components, immediately unlocking higher efficiency and more responsive system behaviour. The trend is clear: valves are no longer just mechanical devices—they're data-driven control points that contribute directly to a building’s operational intelligence.

Predictive maintenance and diagnostics

Predictive maintenance is becoming a priority across many industrial sectors, particularly where system downtime carries high costs. Energy valves contribute to this shift by providing early-warning data that helps detect and address potential failures before they affect performance.

By monitoring flow consistency, ΔT behaviour, and response time, energy valves can highlight problems such as fouled coils, air ingress, or valve sticking. Engineers are alerted to anomalies before they escalate, enabling targeted interventions rather than generalised service checks. This approach reduces unnecessary site visits, lowers maintenance costs, and helps protect against unplanned system interruptions.

As these diagnostic capabilities improve, they will become more autonomous, with BMS platforms taking corrective action automatically based on valve feedback. This will mark a shift from reactive maintenance to fully intelligent, self-optimising systems.

Advancements in IoT-driven energy control

The future of valve technology will increasingly rely on IoT capabilities. Modern energy valves are already capable of cloud integration, allowing operators to access live and historical performance data from anywhere. This facilitates benchmarking across multiple assets, supports energy compliance audits, and makes cross-site optimisation more manageable.

Expect future iterations to include enhanced machine learning features, allowing the valve to learn from previous behaviour and adjust performance accordingly. As data quality improves, these algorithms will become better at identifying inefficiencies and proposing solutions. This transition will enable valves to move beyond control and diagnostics, becoming active participants in energy strategy.

Final Considerations for Specifiers and Engineers

Key factors when selecting an energy valve

When specifying an energy valve, several criteria must be considered beyond simple flow capacity. The compatibility of communication protocols with existing BMS platforms is essential to ensure full functionality. Engineers should also assess the valve’s diagnostic features, response time, and ability to manage ΔT effectively.

In addition, space constraints may dictate valve size and installation configuration. Many modern energy valves are compact and modular, making them suitable for tight plantrooms or retrofit projects. Finally, the availability of local support, including commissioning and servicing expertise, can significantly affect long-term performance and return on investment.

Compatibility with legacy systems

Integrating energy valves into legacy systems presents both challenges and opportunities. Older systems may lack the digital infrastructure required to support full smart functionality. In these cases, the valve’s standalone capabilities—such as local diagnostics and on-device controls—still offer clear benefits.

Specifiers should evaluate whether upgrades to the BMS or control wiring are justified by the expected energy and maintenance savings. Where full integration isn’t immediately feasible, energy valves can still provide valuable flow regulation and metering capabilities, serving as stepping stones in the broader digital transition.

Importance of system-level thinking in valve selection

Valves should never be considered in isolation. The performance of an energy valve depends on its interaction with other system components, including pumps, coils, and sensors. A successful installation begins with a system-level approach, where every part is selected and calibrated to work in harmony.

In this context, energy valves act as both control devices and performance monitors. They bridge the gap between mechanical function and digital insight, giving engineers the tools to create highly efficient, resilient systems. By considering the entire hydronic architecture—rather than just individual parts—specifiers can ensure optimal outcomes both technically and economically.