Overload Coordination Techniques For Modular Socket Box Protection

In demanding factory environments where continuity and safety matter, an industrial socket box plays a central role in both grounding practice and overload management. Proper earthing and correctly rated protective devices reduce risk for people and plant equipment while simplifying inspection routines for technicians. When teams design or specify distribution housings, attention to bonding paths, terminal durability, and accessible protection elements yields systems that stand up to heavy duty use and routine service.

Grounding begins with a clear plan for equipotential bonding. The goal is to keep metal enclosures and chassis at a uniform potential so that accidental faults do not create dangerous touch voltages. A robust grounding stud inside a box provides a secure point to terminate green and green yellow conductors. Installers choose lugs sized to match conductor cross sections and torque values recommended by manufacturers. A low impedance path from incoming service to outgoing metalwork helps direct fault currents into breakers quickly, enabling fast interruption and lowering energy delivered into a fault.

Material selection affects how bonding performs over time. Copper rich terminals and plated fastening hardware resist corrosion and preserve contact integrity in humid or industrial atmospheres. Mechanical clamps that resist vibration prevent loosening under load cycles. When enclosures sit outdoors or in washdown zones, sealing gland fittings and protected entry points stop moisture from reaching grounding terminations. These choices reduce the need for repeated maintenance and lessen the chance that a compromised connection will elevate resistance and generate heat.

Overload protection sits alongside grounding as the other core safety measure. Devices that sense sustained overcurrent remove energy from a circuit before wiring and equipment reach hazardous temperatures. Circuit breakers and thermal magnetic devices offer both manual reset and automatic trip mechanisms. In many industrial setups designers place protective units close to the load to limit the length of unprotected conductor and simplify fault isolation. Fusible links remain useful in certain mobile or legacy applications where simple replaceable elements suit field repair workflows.

Coordination between upstream and downstream devices matters for service continuity. Selective settings avoid a minor fault tripping a broad feeder while clearing only the affected branch. This discrimination lets other parts of a line remain energized, which supports production continuity and reduces the number of manual interventions required during a stop. Properly documented coordination curves and labeled breakers help maintenance teams respond faster and restore service with confidence.

Thermal management links to both earthing and overcurrent protection. Loose terminals and undersized conductors generate resistive heating that oxidizes contacts and weakens bonds. Regular torque checks, infrared scans, and visual inspections of terminations detect hotspots early. Many modern socket housings accept thermal sensors or port connectors that feed panel level monitoring systems. These small additions provide alerts before failures occur and fit into wider predictive maintenance programs.

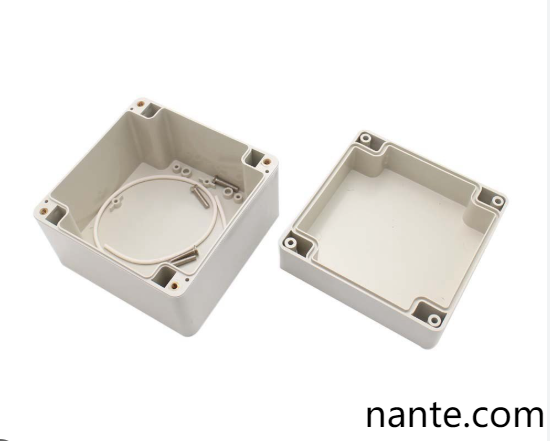

Accessibility of protection modules improves safety and turnover. Enclosures with removable trays allow breakers and surge devices to be replaced without disturbing adjacent circuits. Clear front panel labeling and captive fasteners ease field work by keeping small parts secure during service. For shared workshop areas or public facilities, lockable doors and tamper resistant fasteners prevent unauthorized access while permitting authorized teams to perform routine checks.

Surge suppression complements overload devices by limiting transient energy that can stress insulation and reduce component life. Whether from switching events or nearby lightning strikes, transient overvoltages arrive at distribution points and can cascade into sensitive electronics. Suppressors integrated into the same box as breakers absorb spikes at the boundary between supply and load, preserving downstream control systems and communication modules.

Documentation and marking support safe operation. Wiring diagrams affixed inside doors, clear labels for grounding points, and step by step isolation procedures reduce human error during maintenance. When emergency shutdown sequences are obvious and circuits are identifiable at a glance, crews spend less time troubleshooting and more time executing repairs. Training based on actual panel layouts prepares teams to respond consistently under pressure.

Choosing a supplier with detailed technical support eases specification and installation. Vendors that publish torque tables, terminal ratings, and compatible accessory lists help designers match components to site demands. Spare parts availability and field replacement kits shorten downtime when service is required. Practical commissioning guides and checklists also help inspectors validate installations and close project handover faster.

Grounding and overload protection in industrial socket boxes form a partnership that defends people and equipment while enabling resilient operations. Thoughtful selection of termination hardware, protective devices, and maintenance practices delivers a distribution solution that meets workplace expectations. For those specifying panels or seeking configurable housings suited to harsh environments, explore product families and accessory kits at https://www.nante.com/product/ . Detailed installation notes, component lists, and contact channels assist project teams in choosing configurations that match their site conditions and safety plans. Technical support and spare part options are available to help maintain steady operation and reduce time to repair.