Clean-in-place Valves – Optimizing Automation and Hygiene in Industrial Systems

Clean-in-place valves are designed for automated cleaning without disassembly, and their efficiency is significantly improved by the use of optimized cleaning nozzles. Effective nozzle placement ensures thorough cleaning, reduces downtime, and maintains the integrity of sensitive processing equipment, which is crucial in food, beverage, and pharmaceutical applications.

The cleaning nozzles market has emerged as a critical segment within industrial equipment, owing to the rising demand for efficient cleaning solutions across various industries. Cleaning nozzles are specialized components used to direct high-pressure liquid, steam, or air onto surfaces to remove debris, dirt, or contaminants. Their applications range from manufacturing plants to food processing units, chemical industries, pharmaceuticals, and even residential cleaning solutions. The increasing emphasis on hygiene, operational efficiency, and maintenance of machinery has propelled the adoption of advanced cleaning nozzles worldwide.

Market Dynamics and Growth Drivers

The growth of the cleaning nozzles market is driven by several key factors. One of the primary drivers is the expanding industrial sector, where high-volume production requires consistent and effective cleaning processes. Industries such as food and beverage, pharmaceuticals, automotive, and chemicals demand precise cleaning solutions to ensure product quality and compliance with regulatory standards. Additionally, the increasing adoption of automated cleaning systems, such as Clean-in-Place (CIP) systems, has further fueled the demand for high-performance cleaning nozzles. These systems reduce labor costs, improve efficiency, and enhance safety by minimizing human exposure to hazardous substances.

Environmental regulations and sustainability initiatives are also influencing market growth. Modern cleaning nozzles are designed to optimize water and chemical usage, reducing wastage and operational costs. This focus on eco-friendly solutions is compelling industries to upgrade their cleaning equipment, thus contributing to market expansion. Furthermore, the ongoing trend of industrial digitalization and smart manufacturing is encouraging the integration of IoT-enabled cleaning systems, which rely on precision nozzles for targeted cleaning operations.

Market Segmentation by Type and Application

The cleaning nozzles market can be segmented based on type, including spray nozzles, rotary nozzles, and ultrasonic nozzles. Spray nozzles are widely used in surface cleaning, coating removal, and sanitation processes, offering uniform distribution of cleaning fluids. Rotary nozzles, known for their high impact and rotating spray patterns, are preferred in heavy-duty cleaning applications, such as tanks, pipelines, and industrial machinery. Ultrasonic nozzles, on the other hand, utilize high-frequency sound waves to achieve deep cleaning at a microscopic level, making them ideal for delicate equipment in the electronics and pharmaceutical sectors.

In terms of application, cleaning nozzles are utilized across diverse sectors. The food and beverage industry relies on sanitary cleaning nozzles to maintain hygiene standards and prevent contamination. Pharmaceutical companies use precision nozzles to clean production equipment without damaging sensitive machinery. The automotive and heavy machinery sectors benefit from durable nozzles capable of removing oil, grease, and other industrial residues. Additionally, cleaning nozzles are increasingly being adopted in residential and commercial cleaning systems, such as pressure washers, to provide efficient and cost-effective cleaning solutions.

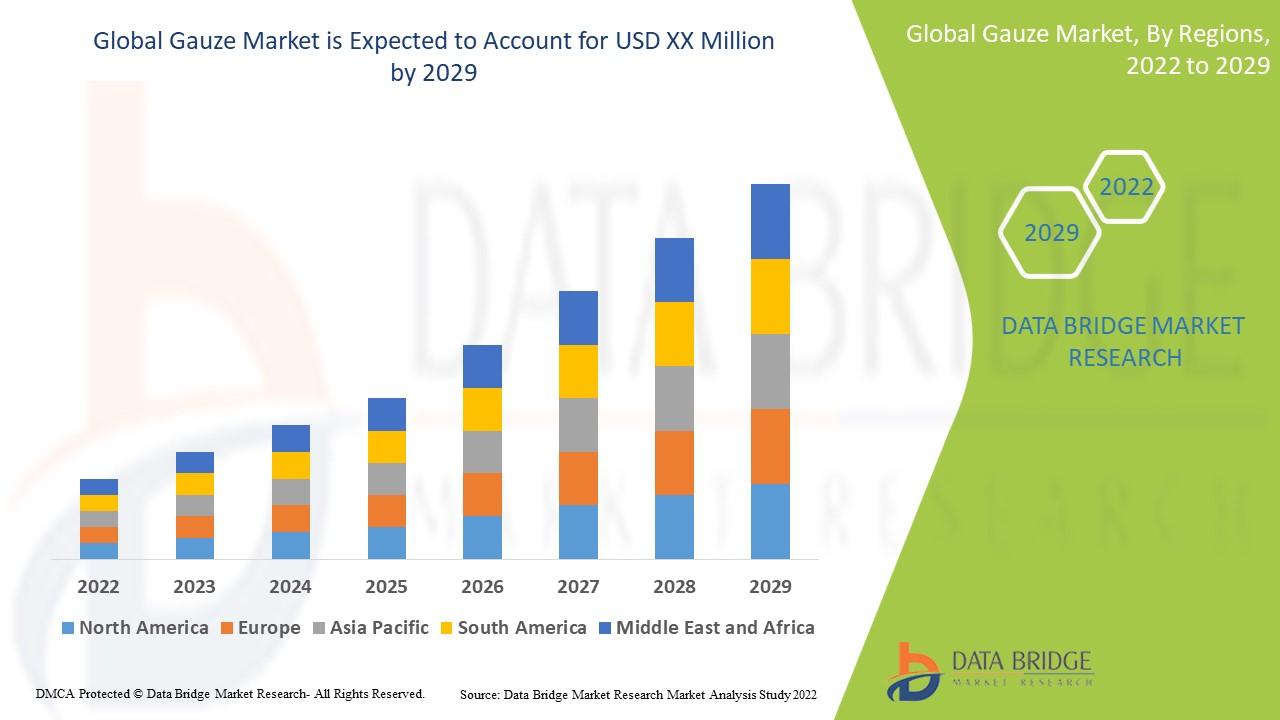

Regional Market Trends

The cleaning nozzles market is witnessing significant growth across multiple regions. North America, driven by technological advancements and stringent sanitation regulations, is a leading market for high-performance cleaning solutions. The United States, in particular, is investing in automation and advanced cleaning technologies, creating demand for specialized nozzles. Europe is another major market, with industries emphasizing sustainable and water-efficient cleaning systems. Countries like Germany and France are adopting smart cleaning solutions integrated with IoT sensors, which enhance operational efficiency and reduce resource consumption.

The Asia-Pacific region is emerging as a high-growth market due to rapid industrialization, urbanization, and the expansion of manufacturing units. Countries like China, India, and Japan are witnessing increased adoption of advanced cleaning technologies, driven by the growing food processing, pharmaceutical, and chemical industries. Latin America and the Middle East & Africa regions are gradually expanding their industrial base, which is expected to create long-term growth opportunities for cleaning nozzle manufacturers.

Technological Innovations and Advancements

Technological innovation plays a crucial role in shaping the cleaning nozzles market. Manufacturers are focusing on designing nozzles that offer enhanced performance, durability, and precision. Materials such as stainless steel, ceramic, and high-grade polymers are being used to improve corrosion resistance and longevity. Advanced nozzle designs now enable uniform spray patterns, adjustable flow rates, and customizable pressure settings to cater to specific industrial requirements.

Moreover, the integration of smart technologies in cleaning nozzles is gaining traction. IoT-enabled nozzles can monitor fluid usage, detect wear and tear, and optimize cleaning cycles, thereby improving operational efficiency. Some companies are also exploring energy-efficient nozzles that reduce water consumption and minimize environmental impact. These technological advancements are not only improving cleaning performance but also reducing operational costs, making the adoption of advanced nozzles an attractive proposition for industries globally.

Challenges and Market Restraints

Despite significant growth, the cleaning nozzles market faces certain challenges. High initial costs associated with advanced nozzle systems can deter small and medium-sized enterprises from adopting the latest technologies. Additionally, the need for skilled operators to handle sophisticated cleaning systems can increase operational complexity. Variations in industrial standards and regulations across different regions may also pose challenges for manufacturers looking to expand globally. Furthermore, intense competition and pricing pressures in the market require companies to continuously innovate while maintaining cost efficiency.

Future Outlook and Opportunities

The future of the cleaning nozzles market appears promising, with increasing opportunities driven by automation, sustainability, and industry-specific requirements. Continuous advancements in materials and smart technologies are expected to enhance the performance and efficiency of cleaning nozzles further. The demand for eco-friendly and water-saving solutions is likely to encourage the development of innovative nozzle designs.

Moreover, as industries continue to focus on hygiene and contamination prevention, particularly in food, pharmaceutical, and healthcare sectors, the demand for high-precision cleaning nozzles will rise. Expansion into emerging markets, coupled with strategic partnerships and technological collaborations, will provide growth avenues for market players.

The cleaning nozzles market has witnessed substantial growth in recent years, driven by increasing industrialization, hygiene awareness, and advancements in cleaning technologies. Cleaning nozzles, essential components in various industrial and commercial cleaning systems, play a critical role in ensuring efficiency, precision, and hygiene across sectors such as food and beverage, pharmaceuticals, chemicals, and manufacturing. These devices are designed to direct fluids under pressure to clean surfaces, machinery, and equipment effectively, ensuring operational safety and productivity. The market’s growth reflects the rising demand for automated and high-efficiency cleaning systems, which minimize human intervention and reduce operational costs while enhancing sanitation standards.

Market Dynamics and Drivers

Several factors contribute to the growth of the cleaning nozzles market. The increasing adoption of automated cleaning systems across industries is a primary driver. Industries are shifting from manual cleaning processes to automated solutions that provide consistent cleaning performance, reduce labor costs, and minimize downtime. Moreover, stringent regulatory standards related to hygiene and sanitation, particularly in the food and pharmaceutical sectors, are compelling businesses to invest in advanced cleaning solutions. The trend toward environmentally friendly and water-efficient cleaning technologies is also boosting demand for innovative nozzle designs that optimize fluid usage without compromising cleaning effectiveness. Additionally, the expansion of manufacturing and processing units in emerging economies is creating significant opportunities for market growth.

Segmentation of Cleaning Nozzles Market

The cleaning nozzles market can be segmented based on type, application, material, and end-use industry. By type, the market includes spray nozzles, jet nozzles, and rotary nozzles, each designed to meet specific cleaning requirements. Spray nozzles are widely used for surface cleaning, while jet nozzles are preferred for heavy-duty industrial cleaning due to their high-pressure performance. Rotary nozzles provide 360-degree coverage, making them ideal for tank cleaning and complex machinery. In terms of material, stainless steel nozzles dominate the market because of their durability, corrosion resistance, and suitability for hygienic applications. Plastic nozzles are also gaining traction due to their cost-effectiveness and lightweight design. Application-wise, cleaning nozzles are deployed in surface cleaning, tank cleaning, pipe cleaning, and equipment maintenance, among other uses.

Industry Applications and Trends

The application of cleaning nozzles extends across multiple industries. In the food and beverage sector, they are essential for maintaining hygiene standards in production lines, processing equipment, and storage tanks. The pharmaceutical industry relies heavily on precision cleaning to prevent contamination during drug manufacturing, making nozzles an integral component of cleaning-in-place (CIP) systems. In chemical processing, nozzles ensure safe and efficient cleaning of reactors, vessels, and pipelines. Additionally, the automotive and metalworking industries use cleaning nozzles to remove debris, oils, and residues from parts and machinery. Recent trends indicate a growing preference for smart nozzles equipped with sensors that monitor flow rates, cleaning pressure, and coverage patterns, enabling predictive maintenance and reducing operational inefficiencies.

Regional Insights

Regionally, the cleaning nozzles market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. North America and Europe lead the market due to established industrial infrastructure, high adoption of automation technologies, and strict hygiene regulations. The Asia-Pacific region is emerging as a high-growth market, driven by rapid industrialization, expanding food processing and pharmaceutical sectors, and increasing investments in modern cleaning technologies. Latin America and the Middle East & Africa are witnessing steady growth due to infrastructure development, rising manufacturing activities, and growing awareness of sanitation standards. The regional expansion of market players through strategic partnerships and localized production facilities is expected to strengthen their market presence further.

Market Challenges

Despite the positive growth outlook, the cleaning nozzles market faces certain challenges. High initial investment costs associated with advanced nozzle systems may deter small and medium-sized enterprises from adopting automated solutions. Moreover, the maintenance and replacement of nozzles can be costly, particularly in high-pressure or corrosive cleaning environments. The market also contends with competition from traditional cleaning methods, where businesses may rely on manual labor to reduce upfront expenses. Addressing these challenges requires manufacturers to innovate cost-effective, durable, and energy-efficient nozzles while offering flexible financing options to attract a broader customer base.

Future Outlook and Opportunities

The future of the cleaning nozzles market looks promising, with numerous opportunities for innovation and expansion. The integration of IoT and smart technologies in cleaning nozzles is likely to redefine the market by enabling real-time monitoring, predictive maintenance, and enhanced efficiency. Water conservation and eco-friendly cleaning solutions are emerging as critical priorities, prompting manufacturers to develop nozzles that optimize water and chemical usage. Additionally, the increasing focus on industrial automation and process optimization across sectors such as pharmaceuticals, food processing, and chemical manufacturing is expected to drive sustained demand. Strategic collaborations, mergers, and acquisitions are anticipated to further enhance market growth, allowing companies to leverage technological advancements and expand into untapped regions.

Conclusion

In conclusion, the cleaning nozzles market is poised for robust growth, fueled by technological advancements, regulatory requirements, and increasing industrial automation. With applications spanning food and beverages, pharmaceuticals, chemicals, and manufacturing, cleaning nozzles are indispensable for maintaining hygiene, efficiency, and operational safety. While challenges such as high costs and competition from traditional methods persist, innovation, automation, and sustainable solutions offer significant opportunities for market players. As industries worldwide continue to prioritize efficiency and cleanliness, the cleaning nozzles market will remain a dynamic and evolving sector, presenting long-term growth potential and transformative possibilities.