Next-Generation Biomanufacturing Market Emerging Insights and Trends 2032

Introduction

The Next-Generation Biomanufacturing Market refers to advanced bioproduction methods designed to enhance the development, scalability, and affordability of biologics. These biologics include monoclonal antibodies, vaccines, cell and gene therapies, and other protein-based therapeutics. Next-generation biomanufacturing integrates innovative platforms such as continuous bioprocessing, single-use technologies, artificial intelligence, and modular facilities to improve efficiency and reduce costs in biopharmaceutical production.

The importance of this market is global, as it directly supports the rapidly expanding biotechnology and pharmaceutical industries. Rising demand for precision medicine, biologics for chronic diseases, and rapid vaccine development has highlighted the need for scalable and efficient biomanufacturing. As of 2024, the market is estimated at USD 25 billion, with a significant growth trajectory expected over the coming decade.

Learn how the Next-Generation Biomanufacturing Market is evolving—insights, trends, and opportunities await. Download report: https://www.databridgemarketresearch.com/reports/global-next-generation-biomanufacturing-market

The Evolution

Biomanufacturing has evolved from traditional batch processes to modern systems emphasizing flexibility, scalability, and real-time monitoring. Historically, the industry relied heavily on stainless-steel bioreactors and large-scale facilities, which were capital-intensive and inflexible.

Key milestones include:

-

1990s: Widespread adoption of bioreactor-based systems for monoclonal antibody production.

-

2000s: Emergence of single-use bioreactors and disposable technologies.

-

2010s: Introduction of continuous bioprocessing, reducing production timelines and costs.

-

2020s: Integration of digital twins, automation, and artificial intelligence for predictive analytics and real-time optimization.

The COVID-19 pandemic accelerated innovation, as demand for rapid vaccine production required scalable and adaptive biomanufacturing solutions. The industry is now shifting toward decentralized and modular facilities to meet global healthcare demands.

Market Trends

-

Rising adoption of single-use technologies to reduce contamination risks and increase flexibility.

-

Transition from batch to continuous bioprocessing, improving yields and reducing costs.

-

Expansion of cell and gene therapy manufacturing, requiring specialized biomanufacturing solutions.

-

Use of artificial intelligence, machine learning, and digital twins for process optimization.

-

Growing importance of personalized medicine driving demand for small-scale, modular facilities.

-

Regional expansion of biomanufacturing hubs in Asia-Pacific and Latin America to reduce dependence on North America and Europe.

-

Increasing collaboration between biopharma companies, CDMOs (Contract Development and Manufacturing Organizations), and technology providers.

Challenges

Despite strong growth potential, the next-generation biomanufacturing market faces several obstacles:

-

Regulatory complexity in approving new bioprocessing methods and ensuring product safety.

-

High upfront costs of transitioning from traditional to next-generation systems.

-

Supply chain vulnerabilities in critical raw materials such as resins, filters, and single-use components.

-

Shortage of skilled professionals trained in advanced bioprocessing technologies.

-

Risk of process variability in novel bioproduction systems.

-

Concerns about scalability for cell and gene therapy products.

Market Scope

Segmentation by Type

-

Upstream Bioprocessing Technologies: Advanced bioreactors, cell culture platforms, and continuous upstream systems.

-

Downstream Bioprocessing Technologies: High-efficiency chromatography, filtration, and purification methods.

-

Single-Use Systems: Bioreactors, bags, tubing, and connectors designed for flexibility and sterility.

-

Automation and Digital Solutions: AI-based analytics, robotics, and process monitoring tools.

Segmentation by Application

-

Monoclonal Antibodies

-

Vaccines

-

Cell and Gene Therapies

-

Recombinant Proteins

-

Biosimilars

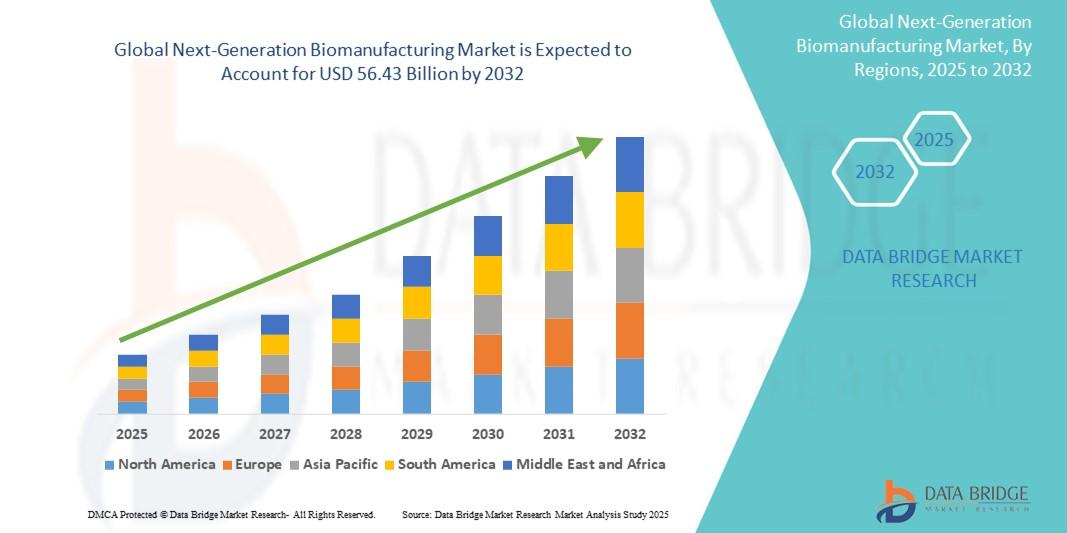

Regional Analysis

-

North America: Strong presence of biopharma companies and early adoption of advanced manufacturing technologies.

-

Europe: Emphasis on biosimilar production and sustainable biomanufacturing practices.

-

Asia-Pacific: Rapidly expanding biopharma sector with significant investments in modular biomanufacturing hubs in China, India, and South Korea.

-

Latin America: Growing demand for affordable biologics and increased local production capabilities.

-

Middle East & Africa: Emerging interest in vaccine and biologics production infrastructure.

End-User Industries

-

Biotechnology companies

-

Pharmaceutical manufacturers

-

Contract Development and Manufacturing Organizations (CDMOs)

-

Research institutes and academic laboratories

-

Hospitals producing personalized therapies

Market Size and Factors Driving Growth

- The global next-generation biomanufacturing market size was valued at USD 26.61 billion in 2024 and is expected to reach USD 56.43 billion by 2032, at a CAGR of 9.85% during the forecast period

Key Growth Drivers

-

Rising global demand for biologics, biosimilars, and gene therapies.

-

Increasing adoption of automation, AI, and continuous manufacturing.

-

Strong investments from governments and private organizations in healthcare infrastructure.

-

Urgency for rapid vaccine development and scalable production.

-

Shift toward personalized medicine, requiring modular and flexible facilities.

-

Growth of contract manufacturing organizations supporting biopharma scalability.

-

Policies promoting sustainable and cost-effective manufacturing practices.

Opportunities in Emerging Regions

-

Asia-Pacific: Establishing itself as a hub for cost-effective biomanufacturing with government support.

-

Latin America: Growing healthcare needs driving local biologics production.

-

Africa: Strategic opportunities for vaccine and biosimilar manufacturing facilities.

-

Middle East: Expanding investments in biotech infrastructure to reduce reliance on imports.

Conclusion

The next-generation biomanufacturing market is positioned for substantial growth, fueled by the rising demand for biologics, gene therapies, and vaccines. Technological innovations such as continuous processing, automation, and single-use systems are reshaping production models, making them more flexible, cost-effective, and scalable.

The outlook to 2035 indicates strong growth opportunities in emerging regions, with Asia-Pacific leading in investment and expansion. For stakeholders, success will depend on adopting sustainable, digitalized, and modular approaches that can meet the evolving demands of the global healthcare landscape. Innovation and sustainability will remain central to future strategies, ensuring resilience and efficiency in biomanufacturing.

FAQ

Q1: What is the current size of the next-generation biomanufacturing market?

The market is valued at USD 25 billion in 2024.

Q2: What is the projected market size by 2035?

It is expected to reach USD 75 billion, growing at a CAGR of 10.5%.

Q3: Which applications dominate the market?

Monoclonal antibodies, vaccines, and cell and gene therapies are the leading segments.

Q4: What technologies are driving growth in this market?

Continuous bioprocessing, single-use technologies, automation, and AI-based solutions.

Q5: What challenges does the market face?

High costs, regulatory hurdles, supply chain disruptions, and workforce skill shortages.

Q6: Which regions are expected to see the highest growth?

Asia-Pacific and Latin America are expected to experience rapid expansion due to rising investments.

Q7: Who are the main end-users of next-generation biomanufacturing?

Biotech firms, pharmaceutical companies, CDMOs, research institutions, and hospitals producing personalized therapies.

Browse More Reports:

Middle East and Africa Olive Oil Market

North America Orthodontic Supplies Market

Asia-Pacific Orthodontic Supplies Market

Europe Polymerase Chain Reaction (PCR) Devices Market

Saudi Arabia Personal Protective Equipment (PPE) Market

Asia-Pacific Plant-Based Egg Market

North America Revenue Cycle Management (RCM) Market

Asia-Pacific Radio-Frequency Identification Technology (RFID) Market

LATAM RFID Tags Market

Middle East and Africa Rotomolding Products Market

Asia-Pacific Satellite Transponder Market

Europe Smart Medical Devices Market

North America Smoking Cessation and Nicotine De-Addictions Market

Europe Sports Analytics Market

Vietnam Talc Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com