Roofing Adhesives Market: Enhancing Durability and Efficiency in Roofing Systems

The construction industry is experiencing a major transformation with increased adoption of advanced materials and technologies. One sector that has witnessed significant progress is the Roofing Adhesives Market, which plays a crucial role in ensuring roof stability, performance, and longevity. Adhesives are now widely preferred for bonding roofing membranes, securing insulation panels, and offering a faster, safer alternative to traditional fastening methods.

With the rise of energy-efficient building codes, adhesives are seen not only as a bonding material but also as enablers of thermal efficiency. This dual functionality makes them a critical component in sustainable construction. Builders, architects, and contractors are increasingly turning to innovative construction adhesives to meet both structural and environmental goals.

Importance of Roofing Adhesives in Modern Projects

Roofing adhesives are designed to provide strong and durable bonds while minimizing installation challenges. Unlike nails and screws, adhesives avoid puncturing the roof surface, which reduces risks of leakage and structural damage.

One of their most important applications is in securing roofing membranes, which protect against rain, UV exposure, and wind uplift. Adhesive application ensures these membranes remain intact and weatherproof, regardless of environmental conditions.

Additionally, adhesives are vital for insulation bonding, keeping insulation boards firmly attached to substrates. Proper bonding maintains energy efficiency, stabilizes indoor temperatures, and lowers energy costs.

Finally, adhesives are a significant subset of construction adhesives, providing specialized solutions that enhance building performance while offering long-term reliability.

Key Market Drivers

- Sustainability in Construction

Adhesives with low VOC emissions align with green building standards. By enabling strong insulation bonding, they directly support energy-efficient structures. - Cost Efficiency and Speed

Compared to mechanical fasteners, adhesives reduce labor requirements, saving both time and costs. They also help preserve the integrity of roofing membranes, avoiding the damage caused by nails and screws. - Supplier Networks

Reliable roofing adhesive suppliers ensure timely availability of products, contributing to smooth construction schedules. Suppliers also play a critical role in educating contractors on adhesive benefits and applications. - Price Sensitivity

Fluctuations in PU roofing adhesive price influence buyer decisions, especially in cost-conscious markets. Competitive pricing remains vital for long-term adoption. - Innovation in Adhesive Technology

The push for eco-friendly and high-performance construction adhesives has spurred research into advanced formulations capable of withstanding extreme climates.

Roofing Adhesives by Application

- Membrane Installation

Adhesives are widely used to bond roofing membranes, ensuring watertight protection and resistance against weathering. - Insulation Panels

Reliable insulation bonding with adhesives helps meet building energy codes by reducing air leaks and thermal loss. - Edge and Detail Work

Adhesives offer superior flexibility, particularly in areas where mechanical fastening is not practical. - Maintenance and Repair

Contractors prefer adhesives for re-roofing projects, where quick, non-intrusive solutions are required.

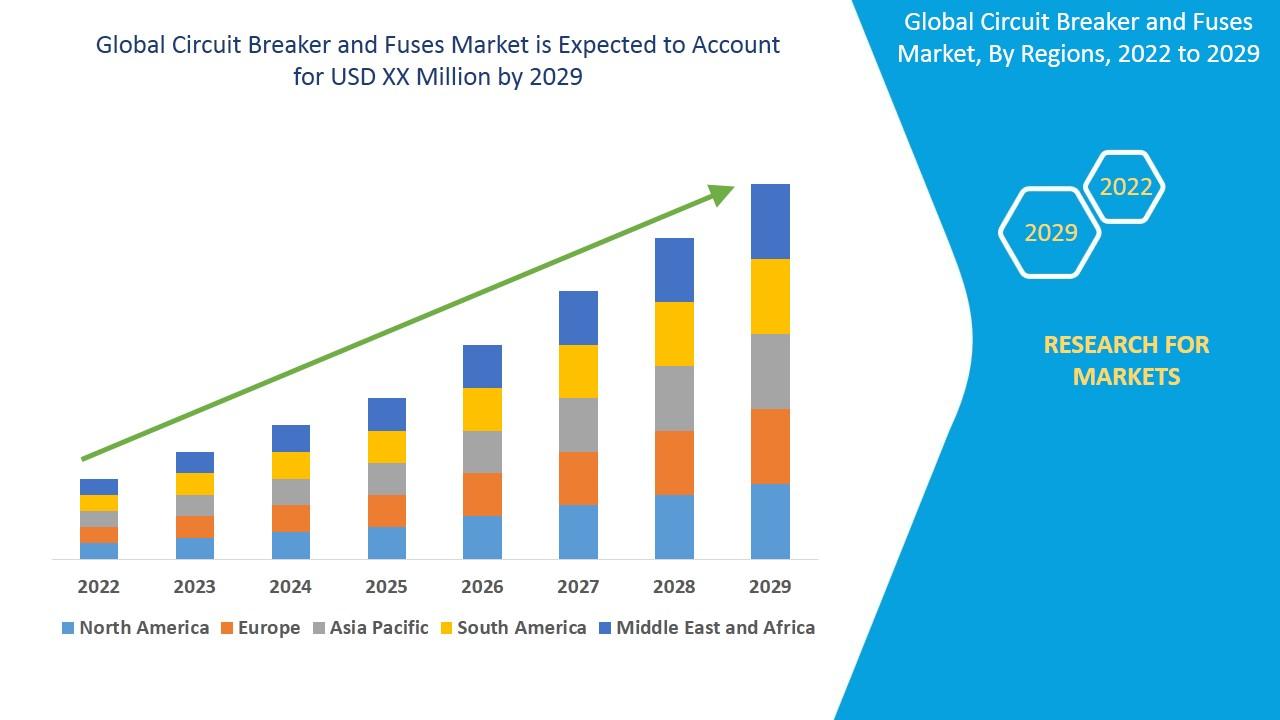

Regional Market Insights

- North America: High adoption of adhesive systems due to frequent re-roofing needs and energy efficiency regulations. Strong networks of roofing adhesive suppliers ensure wide product availability.

- Europe: Stringent environmental laws favor adhesives with low emissions. The region emphasizes eco-friendly construction adhesives and sustainable practices.

- Asia-Pacific: Massive infrastructure growth creates demand for affordable adhesives, with buyers monitoring PU roofing adhesive price trends closely.

- Middle East & Africa: Hot climates require adhesives with superior UV resistance to secure roofing membranes effectively.

Types of Roofing Adhesives

- Polyurethane (PU) Adhesives

Known for excellent adhesion and flexibility, PU adhesives are highly popular. However, fluctuations in PU roofing adhesive price can affect purchasing trends. - Acrylic Adhesives

Cost-effective and UV-resistant, acrylic adhesives are used for bonding roofing membranes in high-sunlight regions. - Epoxy Adhesives

Epoxies offer high strength and durability, making them an important part of specialized construction adhesives markets. - Silicone Adhesives

Silicone products provide excellent elasticity, making them suitable for complex roofing structures and effective insulation bonding.

Competitive Landscape

The roofing adhesives market is characterized by competition among global and regional players. Companies are focusing on product innovation, expanding distribution channels, and offering flexible pricing models to gain an edge.

Roofing adhesive suppliers play a crucial role in bridging the gap between manufacturers and contractors. Their ability to provide detailed technical support, pricing information, and product availability directly impacts buyer choices.

At the same time, PU roofing adhesive price transparency has become a major selling point, with many companies leveraging digital platforms to keep customers informed in real time.

Innovation and Sustainability

As the demand for sustainable buildings grows, adhesive manufacturers are prioritizing eco-friendly solutions. Modern construction adhesives are being developed to minimize carbon footprint while offering superior performance.

Adhesives that improve the lifespan of roofing membranes and enhance insulation bonding are especially popular in markets where energy efficiency is a priority. Manufacturers are also experimenting with bio-based adhesives to reduce dependency on petrochemicals.

Challenges Ahead

While growth prospects are strong, the market does face challenges:

- Price volatility in raw materials impacts PU roofing adhesive price stability.

- Limited awareness about the long-term benefits of adhesives over mechanical fasteners in certain regions.

- Variations in building codes and regulations across countries that affect the adoption of construction adhesives.

Future Outlook

The future of the roofing adhesives market looks promising. Rapid adoption of adhesives in roofing applications, particularly in insulation bonding, is expected to continue. With the growing importance of energy-efficient construction, adhesives that secure roofing membranes without compromising structural integrity will remain in high demand.

Collaboration among manufacturers and roofing adhesive suppliers will be essential for expanding market reach. Furthermore, the development of advanced construction adhesives will ensure strong growth potential despite occasional challenges in PU roofing adhesive price.

Conclusion

The Roofing Adhesives Market has become a cornerstone of modern construction practices. From securing roofing membranes to supporting efficient insulation bonding, adhesives are revolutionizing roofing by offering durability, sustainability, and cost efficiency.

The role of roofing adhesive suppliers is increasingly vital, ensuring that products reach contractors and builders effectively. Meanwhile, ongoing innovation in construction adhesives continues to shape the market’s future.

Although PU roofing adhesive price fluctuations may influence short-term buying patterns, the long-term growth trajectory remains strong. With continuous advancements and expanding global demand, roofing adhesives are set to play an even greater role in the construction landscape of tomorrow.