3D Printing Materials Market Poised for Transformation with Sustainable Materials and Advanced Manufacturing Trends

The 3D printing materials market is undergoing significant transformation as industries increasingly adopt additive manufacturing to enhance efficiency, reduce costs, and enable complex designs. With rapid technological advancements, the demand for specialized and sustainable materials is reshaping the manufacturing ecosystem globally.

Rising Demand Across Industries

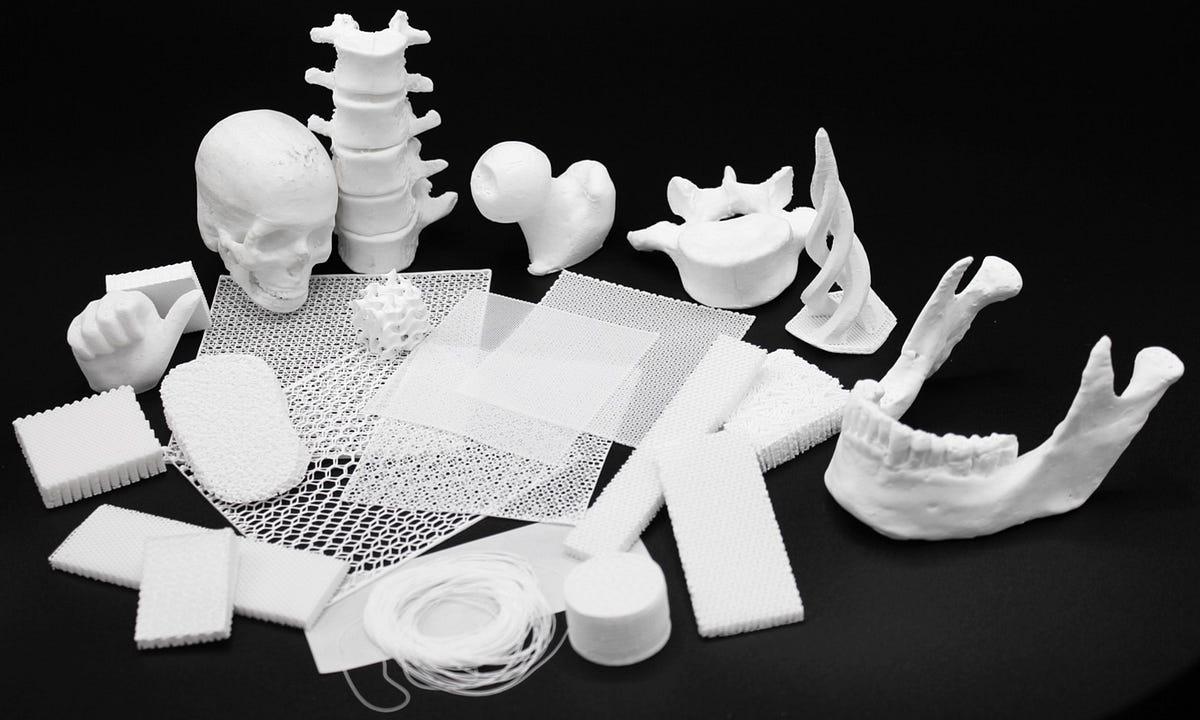

Additive manufacturing has moved beyond prototyping into large-scale production across various sectors. Automotive companies leverage 3D printing to design lightweight, durable parts that improve fuel efficiency and reduce emissions. Aerospace manufacturers utilize advanced materials to build high-strength components while maintaining structural integrity. In healthcare, biocompatible materials are enabling customized prosthetics, dental implants, and even experimental tissue engineering. Similarly, consumer goods and electronics industries are increasingly adopting 3D printing for rapid product development and personalized solutions.

The expanding scope of these applications directly fuels demand for innovative materials that combine mechanical strength, heat resistance, and sustainability.

Key Material Categories Driving Market Growth

The growth of the 3D printing materials market is primarily defined by four major categories:

-

Polymers – Thermoplastics such as PLA, ABS, and nylon dominate entry-level and professional applications. These materials are cost-effective and versatile, supporting industries from consumer products to prototyping.

-

Metals – Titanium, aluminum, stainless steel, and nickel alloys are gaining traction in aerospace, automotive, and healthcare. Their ability to withstand high stress makes them ideal for critical components.

-

Ceramics – Emerging as a strong contender, ceramics are used in dental applications, jewelry, and high-performance engineering due to their heat resistance and durability.

-

Composites and Biodegradable Materials – Hybrid composites improve strength-to-weight ratios, while biodegradable and bio-based polymers support sustainability initiatives in manufacturing.

Technological Innovations Shaping the Market

Advances in additive manufacturing technologies are directly influencing the evolution of materials. For instance:

-

Powder bed fusion methods demand fine, high-performance powders that ensure precision and consistency.

-

Material extrusion requires polymers with improved printability and layer adhesion.

-

Vat photopolymerization relies on liquid resins with specialized curing properties for high-detail products.

Manufacturers are also investing in functional materials with conductive, magnetic, or antimicrobial properties, opening new horizons in electronics, healthcare, and defense applications.

Sustainability as a Core Market Driver

Environmental concerns are pushing industries to adopt eco-friendly materials. Bioplastics and recycled polymers are becoming mainstream, reducing reliance on fossil-based feedstocks. Companies are also experimenting with circular economy approaches, where waste from one process becomes raw material for another.

For instance, recycled filaments derived from plastic waste are now entering commercial supply chains. This trend aligns with global initiatives for sustainable manufacturing and offers companies a way to meet stringent regulatory and consumer demands.

Regional Market Dynamics

-

North America leads with strong adoption in aerospace, defense, and medical sectors. Government funding and private R&D investments are accelerating material innovation.

-

Europe emphasizes sustainability and quality standards, with significant uptake in automotive and industrial manufacturing. Countries like Germany and the UK are central hubs for additive manufacturing.

-

Asia-Pacific is witnessing the fastest growth due to large-scale manufacturing in China, Japan, and South Korea. Strong electronics and consumer goods industries are driving demand for cost-effective, high-performance materials.

-

Middle East and Latin America are gradually adopting 3D printing, primarily in construction, energy, and healthcare, showcasing untapped opportunities.

Challenges Facing the Market

Despite promising growth, several challenges remain:

-

High Material Costs – Premium materials, especially metals and composites, are expensive, limiting adoption in small and medium enterprises.

-

Standardization Issues – Lack of global standards for material quality, testing, and certification slows large-scale adoption.

-

Supply Chain Complexity – Dependence on specialized suppliers and limited availability of certain powders or resins can affect production efficiency.

Addressing these barriers through cost optimization, improved supply networks, and standardization efforts will be key to unlocking broader adoption.

Future Outlook

The future of the 3D printing materials market is tied to innovation, scalability, and sustainability. Emerging technologies such as 4D printing—where materials change properties over time—are expected to create new market frontiers. Additionally, collaborations between material scientists, manufacturers, and end-users will drive faster commercialization of next-generation materials.

With industries seeking customization, efficiency, and eco-friendly alternatives, the demand for advanced materials will only accelerate. By 2035, the market is expected to evolve from niche usage into a cornerstone of modern manufacturing.

Conclusion

The 3D printing materials market is at the forefront of industrial transformation, driven by technological innovation, cross-industry adoption, and sustainability. While challenges remain, ongoing advancements in material science promise a dynamic future where additive manufacturing becomes central to global production strategies.