Sustainability and Cost-Efficiency Propel Growth of Global Mining Remanufacturing Components Market

Latest Insights on Executive Summary Mining Remanufacturing Components Market Share and Size

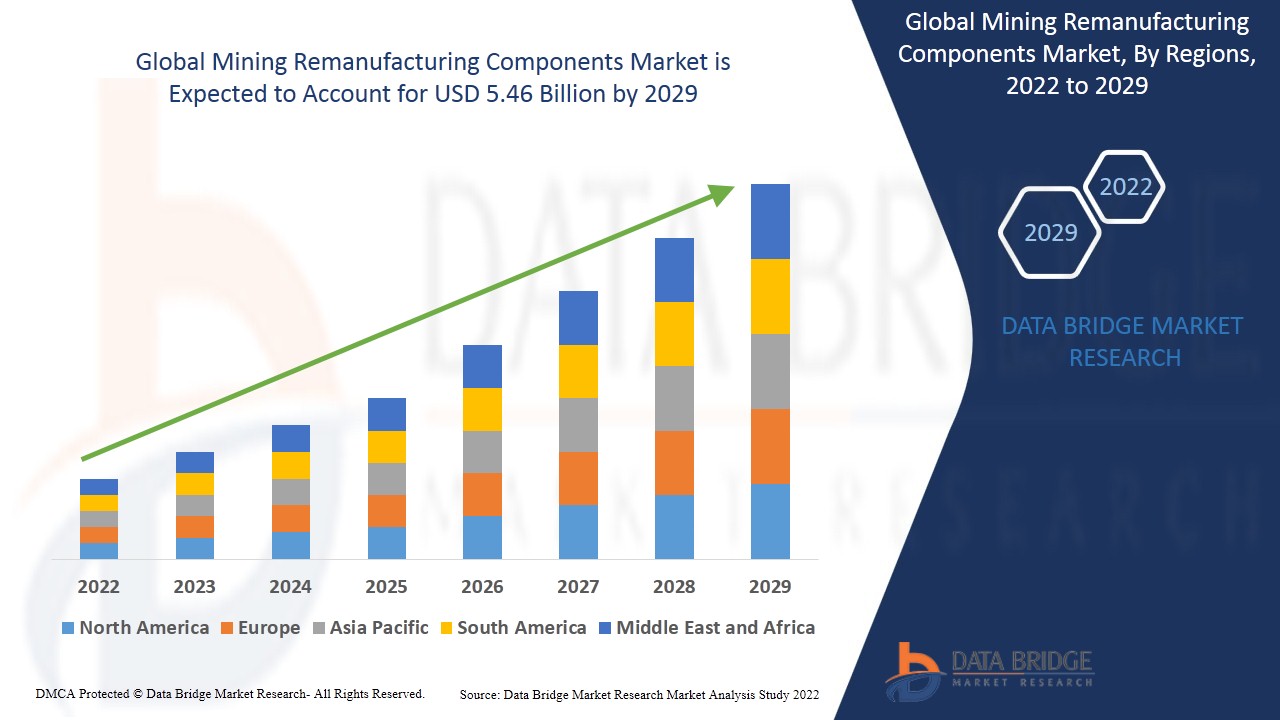

Global Mining Remanufacturing Components Market was valued at USD 4.09 billion in 2021 and is expected to reach USD 5.46 billion by 2029, registering a CAGR of 3.70% during the forecast period of 2022-2029.

Mining Remanufacturing Components Market report presents the best market opportunities available and efficient information with which business can reach towards the growth and success. The industry report offers complete overview of the Mining Remanufacturing Components Market industry that takes into account various aspects of product definition, market segmentation, and the existing retailer landscape. Statistical and numerical data mentioned in the report is represented with the help of graphs and tables which simplifies the understanding of facts and figures. Moreover, a credible Mining Remanufacturing Components Market research report incorporates historic data, current market trends, market environment, technological innovation, upcoming technologies and the technical progress in the related industry.

The comprehensive Mining Remanufacturing Components Market research report is framed by using integrated advancements and latest technology to give the most excellent results. A method of standard market research analysis is put forth while elaborating the studies and estimations that are involved in this market report. Such plentiful information accompanied with deep market insights supports the decision of increasing or decreasing the production of goods depending on the general conditions of market and demand. Mining Remanufacturing Components Market business report has a lot to offer to both established and new players in the Mining Remanufacturing Components Market industry with which they can completely understand the market.

Dive into the future of the Mining Remanufacturing Components Market with our comprehensive analysis. Download now:

https://www.databridgemarketresearch.com/reports/global-mining-remanufacturing-components-market

Mining Remanufacturing Components Business Outlook

**Segments**

- **Component Type:** The mining remanufacturing components market can be segmented based on component type into engines, transmissions, hydraulic cylinders, axles, final drives, and other components. Each of these components plays a crucial role in the functioning of mining equipment, and the demand for remanufactured versions continues to rise due to cost-effectiveness and sustainability benefits.

- **Equipment Type:** Another important segmentation factor is equipment type, including surface mining equipment and underground mining equipment. Surface mining equipment such as excavators, draglines, and loaders often require remanufactured components to enhance performance and extend lifespan. Similarly, underground mining equipment like continuous miners and shuttle cars can benefit from remanufacturing solutions to optimize operations.

- **Region:** Geographically, the mining remanufacturing components market can be segmented into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Each region has its own unique dynamics and market drivers influencing the adoption of remanufactured components in the mining industry. Factors such as regulatory policies, technological advancements, and mining activities play a vital role in shaping the market landscape.

**Market Players**

- **Caterpillar Inc.:** A leading player in the mining remanufacturing components market, Caterpillar offers a wide range of remanufactured parts and components for mining equipment. With a strong focus on sustainability and cost-effective solutions, Caterpillar remains a key player in providing reliable remanufacturing options to the mining sector.

- **Komatsu Ltd.:** Komatsu is another prominent market player that provides remanufacturing components for mining equipment. The company's commitment to quality, innovation, and customer satisfaction has established it as a trusted partner for mining companies looking to optimize their equipment performance through remanufactured components.

- **Liebherr Group:** Liebherr Group is known for its comprehensive range of remanufacturing services for mining equipment components. By leveraging advanced technologies and industry expertise, Liebherr offers tailored remanufacturing solutions that enhance equipment reliability and efficiency, catering to the evolving needs of the mining industry.

- **Sandvik AB:** Sandvik AB is a key player in the mining remanufacturing components market, providing cutting-edge remanufactured parts and components for mining machinery. The company's focus on sustainability and technological innovation sets it apart in delivering superior remanufacturing solutions that drive operational excellence in the mining sector.

In conclusion, the mining remanufacturing components market is witnessing significant growth driven by the increasing emphasis on sustainability, cost-efficiency, and equipment performance optimization in the mining industry. With key players like Caterpillar, Komatsu, Liebherr, and Sandvik leading the market with their innovative remanufacturing offerings, the future looks promising for the market segment. By addressing the evolving needs of mining companies globally and providing reliable remanufactured solutions, these market players are poised to capitalize on the growing demand for sustainable mining practices.

The mining remanufacturing components market is a dynamic sector that continues to evolve, driven by factors such as sustainability, cost-efficiency, and the need for enhanced equipment performance in the mining industry. One key trend shaping the market is the increasing focus on sustainable practices, with mining companies seeking remanufactured components as a way to reduce environmental impact and promote circular economy principles. The shift towards remanufacturing also aligns with the broader industry trend of adopting greener technologies and practices to meet regulatory requirements and enhance corporate social responsibility initiatives.

Moreover, the market is witnessing a rise in demand for remanufactured components across different component types such as engines, transmissions, hydraulics, and axles. This trend is driven by the cost-effectiveness and sustainability benefits offered by remanufactured components compared to new ones. Mining companies are increasingly recognizing the value of investing in remanufactured components to extend the lifespan of their equipment, reduce downtime, and optimize overall operational efficiency.

In terms of equipment type segmentation, both surface mining equipment and underground mining equipment present significant opportunities for remanufacturing solutions. Surface mining equipment, including excavators and loaders, often require remanufactured components to improve performance and productivity. Similarly, underground mining equipment such as continuous miners and shuttle cars can benefit from remanufacturing services to ensure smooth operations and operational continuity.

From a regional perspective, the mining remanufacturing components market exhibits varying dynamics across regions such as North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region has its own set of market drivers and challenges influencing the adoption of remanufactured components in the mining industry. Factors such as regulatory frameworks, technological advancements, and the maturity of the mining sector play a crucial role in shaping market trends and opportunities in each region.

Key market players like Caterpillar, Komatsu, Liebherr, and Sandvik continue to drive innovation and competitiveness in the mining remanufacturing components market. These companies offer a diverse range of remanufactured parts and components that cater to the specific needs of mining companies worldwide. By focusing on sustainability, quality, and technological advancements, these market players are well-positioned to capitalize on the growing demand for remanufactured solutions in the mining industry.

In conclusion, the mining remanufacturing components market presents significant growth prospects fueled by the increasing emphasis on sustainability and operational efficiency in the mining sector. As the industry continues to embrace remanufacturing as a viable solution for equipment optimization and cost savings, market players are expected to innovate further and expand their offerings to meet the evolving needs of mining companies globally. Through strategic partnerships, technological advancements, and tailored solutions, the market is poised for continued growth and transformation in the coming years.The mining remanufacturing components market is poised for continued growth and transformation as sustainability, cost-efficiency, and equipment performance optimization drive demand in the mining industry. Market players like Caterpillar, Komatsu, Liebherr, and Sandvik are at the forefront of innovation, offering a wide range of remanufactured parts and components tailored to meet the specific needs of mining companies globally. These companies are focused on sustainability practices, quality, and technological advancements to provide superior remanufacturing solutions that enhance equipment reliability, efficiency, and overall operational excellence in the mining sector.

One of the key trends shaping the market is the increasing emphasis on sustainable practices, with mining companies adopting remanufactured components to reduce environmental impact and promote circular economy principles. The shift towards remanufacturing aligns with the broader industry trend of embracing greener technologies and practices to meet regulatory requirements and improve corporate social responsibility initiatives. This trend is driving mining companies to invest in remanufactured components to not only extend equipment lifespan but also reduce downtime and optimize operational efficiency.

Furthermore, the demand for remanufactured components is rising across various component types such as engines, transmissions, hydraulic cylinders, axles, final drives, and other critical parts. The cost-effectiveness and sustainability benefits offered by remanufactured components compared to new ones are driving mining companies to recognize the value of such investments. By opting for remanufactured components, mining companies can enhance equipment performance, extend the lifespan of their machinery, and ultimately optimize their operational processes for increased productivity and cost savings.

On the equipment type segmentation front, both surface mining equipment and underground mining equipment present significant opportunities for remanufacturing solutions. Surface mining equipment, including excavators, draglines, and loaders, often require remanufactured components to boost performance and productivity levels. Similarly, underground mining equipment such as continuous miners and shuttle cars can benefit from remanufacturing services to ensure seamless operations and uninterrupted production cycles. The market players are focusing on developing advanced remanufacturing solutions tailored to address the specific needs of each equipment type, further driving market growth and customer satisfaction.

In conclusion, the mining remanufacturing components market is expected to witness continued growth and innovation driven by the increasing focus on sustainability, cost-efficiency, and equipment performance optimization in the mining industry. Market players' emphasis on sustainability, quality, and technological advancements positions them well to capitalize on the growing demand for remanufactured solutions worldwide. By offering diverse and reliable remanufactured parts and components, these companies are playing a crucial role in shaping the future of the mining industry towards more sustainable and efficient practices.

Analyze detailed figures on the company’s market share

https://www.databridgemarketresearch.com/reports/global-mining-remanufacturing-components-market/companies

Mining Remanufacturing Components Market – Analyst-Ready Question Batches

- What is the base year market size of the Mining Remanufacturing Components Market?

- What is the compound annual growth rate of the Mining Remanufacturing Components Market?

- What are the major use cases or applications in this Mining Remanufacturing Components Market?

- Who are the most influential players in this Mining Remanufacturing Components Market industry?

- What strategic product launches have occurred recently?

- What geographic breakdown is offered in the Mining Remanufacturing Components Market report?

- What area is considered a growth hotspot?

- Which nation shows the most promising opportunity?

- Which geographic area dominates revenue generation?

- What macro trends are supporting industry growth for Mining Remanufacturing Components Market?

Browse More Reports:

Global Feed Formic Acid Market

Global Ferroelectric Random-Access Memory (FRAM) Market

Global Fetal Alcohol Spectrum Disorder (FASD) Market

Global Fiber Optic Connectors Market

Global Fiberglass Reinforced Plastics (FRP) Dual Laminate Tank Market

Global Fiberoptic Phototherapy Equipment Market

Global Fibrate Drugs Market

Global Fibre Reinforced Plastic (FRP) Rebar Market

Global Filter Integrity Test Market

Global Flame Retardants Market

Global Flash Field Programmable Gate Array Market

Global Flexible Packaging for Healthcare Market

Global Fluorescein Angiography Market

Global Foam-based Beauty and Personal Care Products Market

Global Food Binders Market

North America Pingueculum Drugs Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"