Tray Sealing Machines Market Forecast: Technological Advancements Revolutionizing Food Packaging Lines Globally

The growing focus on efficiency, food safety, and sustainability is reshaping the tray sealing machines market worldwide. With consumers demanding fresher, safer, and more environmentally friendly food products, packaging lines are being retooled with smarter, more capable tray sealing technology. Advances in materials, automation, monitoring, and sealing methods are together set to drive a new era of food packaging performance—and those changes are already unfolding across processing plants from Asia to Europe to the Americas.

Innovations Driving the Transformation

-

Integration of Smart Sensors, IoT, and Real‑Time Monitoring

Modern tray sealing machines are being equipped with sensors that monitor sealing quality, film alignment, temperature, pressure, and even humidity. Connected via the Internet of Things (IoT), these machines feed data into dashboards or control systems that allow for live tracking of any deviation from optimal sealing parameters. This enables predictive maintenance, early detection of faults (like poor seals), and better uptime. Rather than waiting for visual checks or batch failures, packaging lines can self‑adjust or flag problems before they escalate.

-

Automation & Robotics in Sealing Lines

High throughput needs are pushing producers to adopt fully automated systems—robotic arms for loading and unloading trays, automated film feeders, reject mechanisms for faulty trays, and vision‑guided alignment systems. Machines are no longer just sealing; they're integrated into larger automated lines. This reduces human error, improves hygiene (less human contact = lower contamination risk), and raises speed. The trend is especially strong in plants handling ready‑to‑eat meals, fresh meats, and high‑volume snack packaging.

-

Advanced Sealing Technologies: MAP, Vacuum Skin, Hybrid Seals

To extend shelf life and preserve freshness, tray sealing machines are increasingly supporting Modified Atmosphere Packaging (MAP), vacuum skin packaging, and other hybrid sealing techniques. These help reduce oxygen, control moisture, or flush with inert gases to minimize spoilage and improve product safety. The ability to integrate these modules into sealing lines allows producers to package perishable food that retains texture, taste, color, and safety for longer durations—while also reducing reliance on preservatives.

-

Material Innovation and Sustainable Tray / Film Compatibility

Environmental pressures are pushing both regulatory bodies and consumers to favor recyclable, biodegradable, compostable, or mono‑material trays and films. To work with these more delicate or varied materials, tray sealing machines are being engineered with more precise control over sealing temperature, pressure, dwell time, and tooling that can adapt to different tray geometries. Also, machines are being designed to minimize film waste and allow quick changeovers between different film or tray types. Some new sealing films have anti‑fog or peelable layers to improve user experience and reduce waste.

-

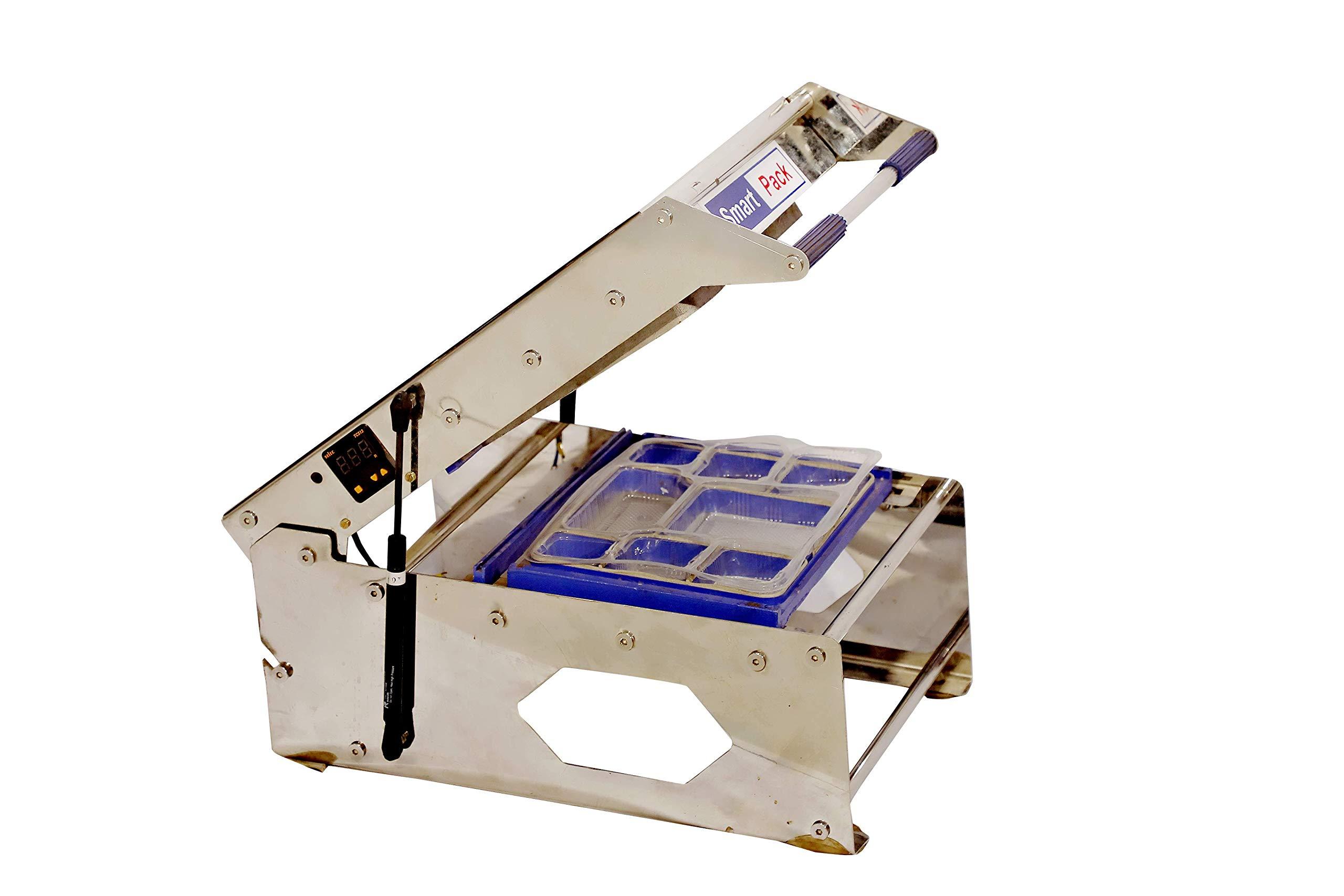

Hygienic Design & Facility Cleanability

Sealing machines are being designed with more hygienic features—stainless steel construction, easy‑clean zones, fewer crevices, quick disassembly, wash‑down compatibility. In many cases, sealing zones are isolated or shielded to prevent contamination. Food safety certifications and hygiene compliance are becoming prerequisites, not afterthoughts. In addition, traceability is incorporated: batch codes, barcode or QR code printers, and inspection systems to confirm seals.

-

Energy Efficiency & Operational Flexibility

Advances also include better insulation, more efficient heating elements, variable power modes, faster warm‑up times, idle modes, and technologies that reduce energy usage per tray. Machines are becoming more flexible—with modular designs that allow manufacturers to scale capacity, swap tray sizes, or adapt formats without large overhauls. This flexibility allows producers to respond to seasonal changes, new products, or changing consumer preferences without investing in wholly new lines each time.

Forecast & Impacts on Food Packaging Lines

-

Faster Cycle Rates and Higher Throughput: As sealing machines become more automated and efficient, cycle times per tray will reduce significantly. Pack lines will handle more volume, reduce backlog, and improve cost‑per‑unit.

-

Lower Waste, Better Shelf Life: With better sealing integrity, MAP and vacuum features, and sustainable materials working well, less product will be spoiled or rejected due to poor seals. This also translates to less film/tray waste.

-

Enhanced Food Safety and Regulatory Compliance: Global and region‑specific food safety regulations will increasingly mandate traceability, hygienic operation, and packaging that prevents contamination. Advanced sealing machines will help producers meet or exceed these standards.

-

Adoption in Emerging Markets: As developed markets push ahead, emerging markets will gain more access to these advanced technologies. Producers in Asia‑Pacific, Latin America, Middle East & Africa are likely to invest more in machines with automation, hygiene, and efficient materials as food processing scale and regulatory oversight grow.

-

Differentiation via Sustainability and Branding: Companies that use eco‑friendly trays, visible fresh packaging, tamper‑evident sealing, and clean designs will be able to leverage packaging as part of their brand story. Consumers are increasingly sensitive to packaging waste, so visual cues of sustainability (e.g. labels, recyclable tray symbols, clear films) will matter.

Challenges to Overcome

-

Cost of Upgrading & ROI: Investing in advanced tray sealing machines is expensive—not just the base machine but integration, staff training, maintenance, parts. For smaller producers, ensuring return on investment may take time.

-

Material Constraints & Compatibility: Some sustainable or biodegradable materials may have different physical properties—lower heat tolerance, less rigidity, different seal adhesion. Machines need to be tuned or designed to handle these variations well.

-

Skilled Labor & Maintenance: Operating highly automated, sensor‑laden sealing lines requires more technical know‑how. Regular maintenance, calibration, and hygienic cleaning must be strict.

-

Supply Chain & Validation: Ensuring quality of films, trays, sensors, spare parts is vital. Also, validation for regulatory compliance (food safety, contact materials, traceability) adds complexity.

Regional Implications

-

Asia‑Pacific is likely to drive much of the growth, given rising populations, increasing urbanization, growing middle classes, and increasing demand for packaged foods. Also, government initiatives in many countries are encouraging food safety upgrades and modern food processing infrastructure.

-

North America and Europe will continue to lead in innovation, regulatory standards, and adoption of premium food packaging formats. Sustainability regulations in Europe especially will push material and energy innovations.

-

Latin America, Middle East & Africa present growing opportunities but may lag slightly due to cost or infrastructure constraints. However, as food distribution networks strengthen and food safety standards rise, these regions will increasingly adopt advanced tray sealing technologies.

In conclusion, technological advancements are revolutionizing food packaging lines globally, and the forecast for tray sealing machines is one of continued innovation, greater efficiency, improved food safety, and sustainability. Companies that stay ahead with smart sealing systems, sustainable materials, and automation will lead this transformation.