Key Processes and Core Requirements for chemical supply

1. Production Link: Compliance as the Premise

- Qualification Requirements: Manufacturing enterprises must hold relevant certificates such as the "Hazardous Chemical Production License" (if hazardous chemicals are involved) and ISO 9001 quality management system certification.

- Quality Control: Inspections must be conducted in accordance with standards, including Incoming Quality Control (IQC) for raw materials, In-Process Quality Control (IPQC), and Final Quality Control (FQC) for finished products. A Certificate of Analysis (COA) must be issued and archived.

- Environmental Protection Requirements: Industrial wastewater and waste gas must be discharged up to standard, complying with national "three wastes" (wastewater, waste gas, solid waste) treatment standards (e.g., China’s GB 18484-2020).

2. Distribution Link: Demand Matching as the Core

- Hierarchical Distribution: First-tier distributors cooperate with large enterprises to provide "bulk centralized procurement"; second-tier distributors focus on small and medium-sized customers, offering services such as "small-batch splitting" and "multi-category integration".

- Compliance Support: A Safety Data Sheet (SDS) must be provided to downstream parties, specifying the chemical’s hazardous properties, first-aid measures, and leakage handling plans.

- Import and Export Services: For cross-border chemical supply, a "Hazardous Chemical Import/Export License" must be obtained, and compliance with the target country’s regulations (e.g., EU REACH, US TSCA) is required.

3. Warehousing and Logistics: Safety as the Bottom Line

-

Warehousing Management:

- Ordinary chemicals: Only well-ventilated and dry warehouses are required.

- Hazardous chemicals: Must be stored in classified areas (e.g., flammable substances in separate explosion-proof warehouses, corrosive substances on anti-corrosion floors, highly toxic substances in cabinets with double locks managed by two persons), with fire-fighting equipment and emergency shower facilities installed.

- Special chemicals: Need temperature-controlled storage (e.g., 2-8℃ for biological reagents) and protection from light.

-

Logistics and Transportation:

- Hazardous chemicals must be transported by specialized vehicles that meet the standards of the UN Recommendations on the Transport of Dangerous Goods (TDG), and escorted throughout the journey by personnel holding a "Hazardous Goods Escort Certificate".

- Cold-chain chemicals (e.g., some biological reagents) must be transported by refrigerated trucks with temperature monitoring to ensure stable temperatures during transportation.

Categorieën

Read More

Asia-Pacific Human Leukocyte Antigen (HLA) Typing for Transplant Market, By Products and Services (Reagents and Consumables, Instruments, Software and Services), Technology (Sequencing- Based Molecular Assays, Molecular Assay Technologies, Non- Molecular Assay Technologies), Transplant Type (Solid Organ Transplant, Haematopoietic Stem Cell Transplant), Application (Diagnostic Applications,...

Precisely inside circumstance it weren distinct a several several hours in the past, the Purple Sox seem to be in the direction of particularly, truly including Addison Reed. They may possibly even which include-together with him, as Mark Feinsand research that Boston considers him the greatest aim for upgrading its team for Reed, towards that short article former at present:Within 49. 0...

Executive Summary Middle East and Africa Sanitary Ware Market : The global ready to drink beverages market was valued at USD 106 billion in 2024 and is expected to reach USD 168.94 billion by 2032, During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 6.00 % primarily driven by the increasing consumer demand for convenient...

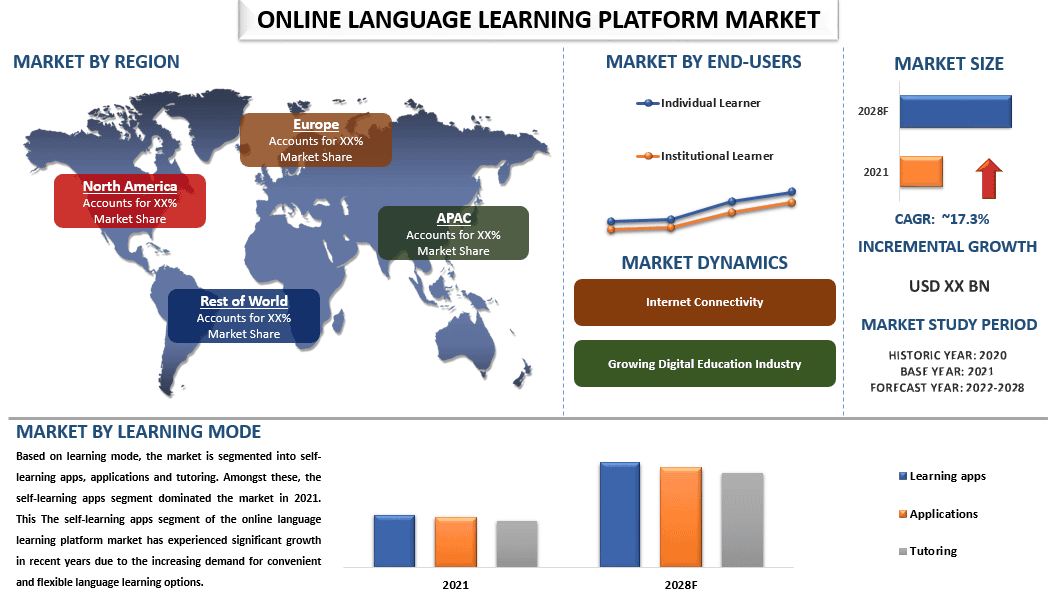

According to the UnivDatos, the Online Language Learning Platform Market is expected to grow at a strong CAGR of 17.29% during the forecast period owing to the increasing online resources and cost-effective learning. In recent years, the world of language learning has experienced a remarkable transformation, largely driven by the proliferation of online language learning startups. This blog...

In the heart of Mumbai’s bustling suburb of Ahmedabad lies a sanctuary where artistry, heritage, and innovation converge—Kalamandir Jewellers. For decades, this iconic brand has transcended the ordinary, crafting jewellery that isn’t merely worn but cherished as heirlooms. With a legacy spanning generations and a footprint stretching from Gujarat to global airport outlets,...