SPM Systems: Transforming Electronics Manufacturing with Precision Inspection

In modern electronics manufacturing, precision and quality are critical to achieving high yields and reducing costly rework. Solder Paste Measurement (SPM) is one of the most important processes in surface mount technology (SMT) assembly, and the right inspection technology ensures consistent, high-quality production. SPM Systems have become essential tools for electronics manufacturers seeking to optimize yields, improve reliability, and maximize profitability. At ASC International, our portfolio of SPM Machines and SPM Equipment delivers advanced inspection capabilities that guarantee measurable results for clients worldwide.

What Are SPM Systems and Why They Matter

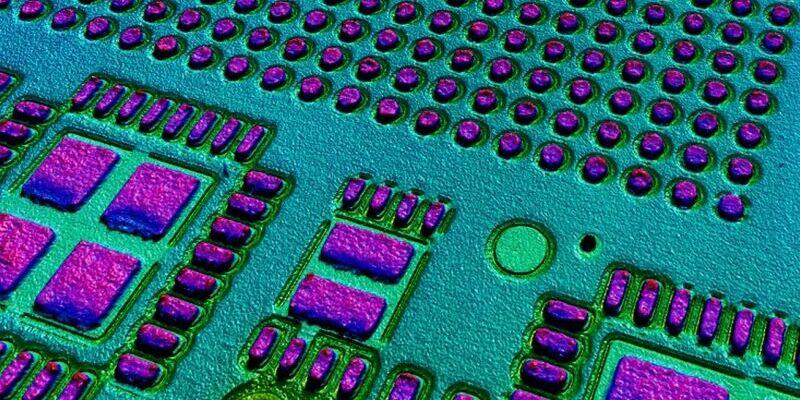

Solder Paste Measurement (SPM) involves analyzing the volume, height, and shape of solder paste deposits applied during PCB stencil printing. Defects in solder paste deposition, such as insufficient volume, misalignment, or bridging, are major contributors to assembly failures. Inline 3D SPM Systems offer a comprehensive solution by measuring solder paste in three dimensions, providing volumetric and area analysis that traditional 2D inspection cannot capture.

By integrating SPM Machines directly into the production line, manufacturers can detect defects immediately after paste printing. This allows for real-time corrective actions, reducing scrap, eliminating costly downstream rework, and improving overall process consistency. Inline 3D SPM Systems are particularly valuable for high-density boards, fine-pitch components, and complex assemblies where precision is non-negotiable.

Key Benefits of SPM Equipment

Investing in SPM Equipment provides tangible advantages for electronics manufacturers.

Early Defect Detection

Inline SPM Systems detect solder paste issues before components are placed, preventing errors from propagating through the SMT line. Catching defects early reduces waste, saves materials, and prevents delays caused by post-reflow failures.

Real-Time Process Feedback

Modern 3D SPM Machines offer closed-loop feedback to the solder paste printer. This allows automatic adjustments to stencil alignment, paste volume, or deposition parameters, ensuring consistent quality and reducing human error.

Yield Improvement

Accurate measurement of solder paste leads to fewer defects, higher first-pass yields, and reduced rework. Companies using ASC International’s SPM Systems often report double-digit improvements in line yield, directly impacting profitability.

High-Speed Scalability

SPM Machines are designed to operate at high speeds, keeping pace with fast SMT lines without introducing bottlenecks. This is crucial for contract manufacturers or OEMs producing high-volume assemblies across multiple shifts.

Enhanced Reliability and Compliance

Accurate solder paste deposition ensures better solder joints and fewer field failures. Detailed inspection records from 3D SPM Systems also provide traceability for quality audits, customer requirements, and regulatory compliance.

Features of Modern 3D SPM Machines

Modern 3D SPM Systems integrate cutting-edge technologies to provide maximum performance:

-

High-resolution 3D imaging sensors measure volume, height, and area of solder paste deposits with micron-level precision.

-

Fast inspection speed ensures high-throughput production without bottlenecks.

-

Closed-loop integration with printers allows automatic adjustments for optimal process control.

-

User-friendly software enables operators to quickly review results and identify defects.

-

Detailed reporting and analytics support continuous improvement programs and yield optimization.

ASC International’s SPM Machines combine these capabilities into robust platforms suitable for production environments of any size. Whether a manufacturer is producing consumer electronics, automotive modules, or medical devices, our 3D SPM Machines deliver reliable results that improve yield and reduce operational costs.

Real-World Impact and ROI

SPM Systems are not just inspection tools—they are profit enablers. Manufacturers who deploy ASC International’s SPM Equipment report significant benefits:

-

Reduced Scrap and Rework: Detecting defects immediately prevents faulty boards from reaching later production stages.

-

Higher Yields: Accurate solder paste deposition improves first-pass yield, reducing material waste and operational costs.

-

Faster Ramp-Up: Inline 3D SPM Machines adapt quickly to new board designs and component packages, reducing time-to-market.

-

Lower Warranty and Return Costs: Higher-quality assemblies result in fewer field failures and stronger customer satisfaction.

For example, a leading automotive electronics manufacturer integrated ASC International’s 3D SPM Systems on multiple SMT lines and achieved a 30% reduction in post-reflow defects within six months. Another consumer electronics OEM improved throughput by 25% and reduced costly rework by 40% after deploying SPM Machines with real-time process feedback. These examples demonstrate the measurable ROI and operational benefits of modern SPM Equipment when paired with expert yield improvement strategies.

Integrating SPM Systems in Smart Manufacturing

In the era of Industry 4.0, SPM Machines play a crucial role in smart factory operations. Inline 3D SPM Systems not only detect defects but also provide actionable data for process improvement. When integrated with manufacturing execution systems (MES) or production analytics platforms, SPM data enables predictive maintenance, real-time monitoring, and continuous optimization of SMT lines. This integration turns inspection into a strategic asset, driving operational excellence and long-term profitability.

Conclusion

SPM Systems, including SPM Machines, SPM Equipment, and 3D SPM Systems, are essential for modern electronics manufacturing. By detecting solder paste defects early, providing real-time process feedback, and supporting high-speed production, these systems ensure high yields, lower costs, and better product reliability. At ASC International, we provide industry-leading SPM solutions combined with a custom yield improvement strategy that guarantees measurable results. Manufacturers who implement our 3D SPM Machines benefit from reduced rework, higher throughput, and stronger competitiveness in their markets.

Frequently Asked Questions (FAQs)

1. What is the difference between 2D and 3D SPM Systems?

3D SPM Systems measure volume, height, and area of solder paste deposits, while 2D systems only capture surface images. This volumetric measurement ensures more accurate defect detection.

2. How do SPM Machines improve production yield?

SPM Machines detect solder paste defects immediately after printing and provide real-time feedback to printers, reducing scrap and rework, which directly improves yield.

3. Can 3D SPM Equipment keep up with high-speed SMT production lines?

Yes. Modern 3D SPM Machines are designed for high-throughput lines, maintaining accuracy without slowing production.

4. Is investing in SPM Equipment cost-effective?

Absolutely. The ROI comes from higher yields, reduced scrap and rework, improved product reliability, and lower warranty costs.