Adsorbent Market Barriers Hindering Growth and Industrial Expansion Globally

Adsorbent Market encounters several barriers that hinder growth and limit adoption across industries such as water treatment, chemicals, pharmaceuticals, and environmental remediation. High production costs, raw material volatility, regulatory compliance, and technical challenges affect operational efficiency and market expansion. This blog explores key barriers, their industrial impact, regional considerations, technological solutions, and strategies companies use to navigate obstacles in the global adsorbent industry.

High Production Costs

One of the major barriers is the high cost of manufacturing advanced adsorbents. Materials like activated carbon, silica, alumina, and hybrid adsorbents require substantial investment in raw materials, energy, and specialized equipment.

High production costs influence pricing strategies and can slow adoption, particularly in cost-sensitive emerging markets. Companies must balance quality, performance, and affordability to remain competitive.

Raw Material Volatility

Fluctuations in raw material availability and pricing present a critical challenge. Dependence on specific suppliers or regions for essential materials like activated carbon or zeolites exposes manufacturers to supply disruptions.

Inconsistent raw material quality can affect adsorption efficiency, product reliability, and industrial performance. Diversified sourcing and alternative materials are essential to mitigate these risks.

Regulatory Compliance

Stringent environmental and industrial regulations act as barriers in different regions. Companies must ensure compliance with chemical handling, wastewater treatment, and air quality standards, which can increase operational costs and production complexity.

While regulations drive demand for eco-friendly adsorbents, they also require manufacturers to maintain rigorous quality control and product consistency, adding to barriers in the market.

Technical Challenges

Advanced adsorbents, such as nano-structured and hybrid materials, require precise manufacturing techniques and skilled labor. Maintaining consistent performance, adsorption capacity, and surface properties is challenging, especially for customized industrial applications.

Investments in research, automation, and process optimization are necessary to overcome technical barriers while ensuring product reliability.

Regional Considerations

Asia Pacific faces barriers such as raw material scarcity, infrastructure limitations, and high industrial demand. North America and Europe contend with high labor costs, regulatory compliance, and technological demands.

Understanding regional barriers is crucial for manufacturers to implement appropriate strategies, optimize production, and maintain competitiveness across global markets.

Market Drivers Amid Barriers

Despite these barriers, industrial demand, environmental regulations, and sustainability initiatives continue to drive the adsorbent market. High-performance, reusable, and eco-friendly adsorbents are sought after for water treatment, chemical purification, pharmaceutical processes, and environmental remediation.

Companies investing in technological innovation, process optimization, and sustainable materials can navigate barriers effectively and capture growth opportunities.

Strategies to Overcome Barriers

Manufacturers address market barriers by diversifying raw material sources, investing in advanced production techniques, and adopting sustainable practices. Strategic partnerships and R&D initiatives help reduce costs and improve efficiency.

Automation, digital monitoring, and process optimization enhance operational efficiency, allowing companies to overcome regulatory, technical, and production challenges effectively.

Future Outlook

The adsorbent market is expected to grow steadily as technological innovation, sustainable practices, and process optimization overcome existing barriers. Nano-structured, hybrid, and bio-based adsorbents will support diverse industrial and environmental applications.

Companies focusing on eco-friendly, high-performance, and cost-efficient materials, while adapting to regional regulatory requirements, will achieve long-term growth and maintain competitiveness in the global adsorbent industry.

Kategorien

Mehr lesen

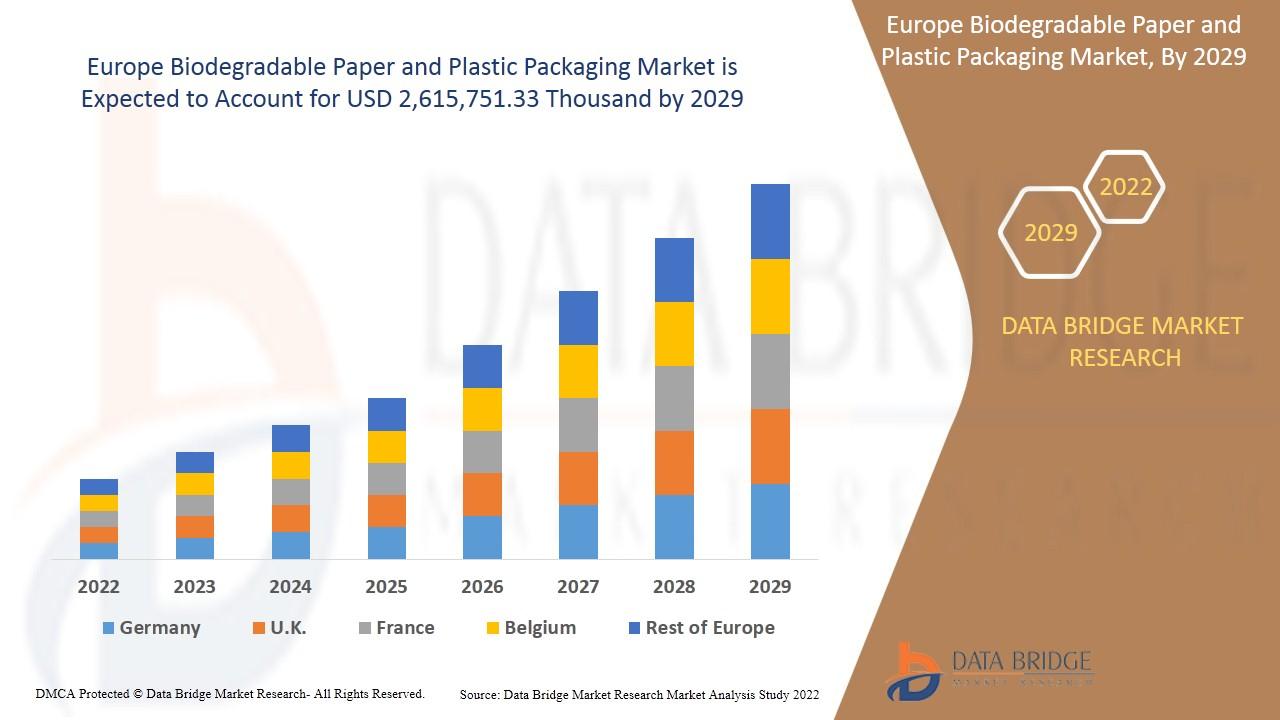

"What’s Fueling Executive Summary Europe Biodegradable Paper and Plastic Packaging Market Size and Share Growth Data Bridge Market Research analyses that the market is growing at a CAGR of 7.8% in the forecast period of 2022 to 2029 and is expected to reach USD 2,615,751.33 thousand by 2029. To stand apart from the competition, a careful idea about the competitive landscape, their product...

The vaping industry continues to evolve rapidly, and one of the standout innovations of recent times is the Lost Mary BM6000. Known for its sleek design, long-lasting battery, and exceptional flavour delivery, this pod-based system is capturing attention from casual and regular vapers alike. In this comprehensive article, we’ll explore everything you need to know about the Lost Mary...

Every successful experiment, research project, or classroom demonstration begins with the right Laboratory Equipment. From basic glass beakers to advanced microscopes, equipment forms the foundation of accurate results, safe handling of chemicals, and effective teaching. At Eqipped, we specialize in supplying a wide range of laboratory equipment that meets the needs of schools, colleges,...

"Executive Summary Bio-based Aromatics Market Size and Share: Global Industry Snapshot The global bio-based aromatics market size was valued at USD 2.77 billion in 2024 and is expected to reach USD 4.25 billion by 2032, at a CAGR of 5.50% during the forecast period For an actionable market insight and lucrative business strategies, a faultless market...

Middleeast Valve is a top Dual plate check valve manufacturers in Saudi Arabia. Opt for suppliers who provide durable, efficient, and industry-compliant solutions tailored to your requirements." What is a Dual Plate Check Valve? A dual plate check valve is a type of non-return valve designed to prevent backflow in pipelines. It features two spring-loaded plates that open when fluid flows...