-

Compressed Bio Gas (CBG): Driving Towards a Renewable Energy Future

As the world continues to grapple with rising energy demands and the urgent need to cut down carbon emissions, renewable energy solutions are taking center stage. Among these, Compressed Bio Gas (CBG) has emerged as one of the most promising and sustainable alternatives to conventional fossil fuels. With its ability to reduce dependence on imported fuels, lower greenhouse gas emissions, and support rural economies, CBG is paving the way for a cleaner and greener energy future.

What is Compressed Bio Gas (CBG)?

CBG is produced through the anaerobic digestion of agricultural residue, cattle dung, sugarcane press mud, municipal solid waste, and other organic matter. The gas generated is purified and compressed to the desired pressure, making it suitable for use in vehicles and as an alternative to CNG (Compressed Natural Gas).

Key Advantages of CBG

Eco-Friendly Fuel: CBG helps in reducing CO₂ emissions significantly, contributing to a cleaner environment.

Import Substitution: By replacing fossil-based fuels, CBG reduces dependency on imported petroleum products.

Waste to Wealth: Agricultural and organic waste is utilized effectively, minimizing landfill issues and open burning.

Economic Opportunities: CBG plants generate employment and additional income streams, particularly in rural areas.

Versatility: CBG can be used for power generation, cooking, and transportation, making it a multi-purpose energy source.

Government Push for CBG

The Indian government has launched several initiatives such as the Sustainable Alternative Towards Affordable Transportation (SATAT) scheme, which aims to set up thousands of CBG plants across the country. These policies not only encourage investment but also ensure assured markets for CBG producers.

CBG and the Road Ahead

With rising global concern over climate change, the shift towards renewable energy is inevitable. CBG, with its scalability and sustainability, is well-positioned to complement other renewable energy sources like solar and wind. As adoption increases, CBG will play a significant role in India’s energy security and environmental sustainability goals.

Conclusion

Compressed Bio Gas (CBG) is more than just an alternative fuel—it is a powerful step toward a sustainable, energy-secure, and environmentally friendly future. By transforming organic waste into a valuable energy source, CBG holds the potential to reshape the way we think about energy.

GasProcessing is committed to driving innovation in renewable energy with advanced Compressed Bio Gas (CBG) solutions. With expertise in sustainable energy systems, GasProcessing helps industries and communities adopt cleaner, greener, and more efficient energy alternatives for a brighter tomorrow.

Visit us https://gasprocessing.in/biogas/

Compressed Bio Gas (CBG)

Compressed Bio Gas (CBG): Driving Towards a Renewable Energy Future As the world continues to grapple with rising energy demands and the urgent need to cut down carbon emissions, renewable energy solutions are taking center stage. Among these, Compressed Bio Gas (CBG) has emerged as one of the most promising and sustainable alternatives to conventional fossil fuels. With its ability to reduce dependence on imported fuels, lower greenhouse gas emissions, and support rural economies, CBG is paving the way for a cleaner and greener energy future. What is Compressed Bio Gas (CBG)? CBG is produced through the anaerobic digestion of agricultural residue, cattle dung, sugarcane press mud, municipal solid waste, and other organic matter. The gas generated is purified and compressed to the desired pressure, making it suitable for use in vehicles and as an alternative to CNG (Compressed Natural Gas). Key Advantages of CBG Eco-Friendly Fuel: CBG helps in reducing CO₂ emissions significantly, contributing to a cleaner environment. Import Substitution: By replacing fossil-based fuels, CBG reduces dependency on imported petroleum products. Waste to Wealth: Agricultural and organic waste is utilized effectively, minimizing landfill issues and open burning. Economic Opportunities: CBG plants generate employment and additional income streams, particularly in rural areas. Versatility: CBG can be used for power generation, cooking, and transportation, making it a multi-purpose energy source. Government Push for CBG The Indian government has launched several initiatives such as the Sustainable Alternative Towards Affordable Transportation (SATAT) scheme, which aims to set up thousands of CBG plants across the country. These policies not only encourage investment but also ensure assured markets for CBG producers. CBG and the Road Ahead With rising global concern over climate change, the shift towards renewable energy is inevitable. CBG, with its scalability and sustainability, is well-positioned to complement other renewable energy sources like solar and wind. As adoption increases, CBG will play a significant role in India’s energy security and environmental sustainability goals. Conclusion Compressed Bio Gas (CBG) is more than just an alternative fuel—it is a powerful step toward a sustainable, energy-secure, and environmentally friendly future. By transforming organic waste into a valuable energy source, CBG holds the potential to reshape the way we think about energy. GasProcessing is committed to driving innovation in renewable energy with advanced Compressed Bio Gas (CBG) solutions. With expertise in sustainable energy systems, GasProcessing helps industries and communities adopt cleaner, greener, and more efficient energy alternatives for a brighter tomorrow. Visit us https://gasprocessing.in/biogas/ Compressed Bio Gas (CBG)0 Comments ·0 Shares ·142 Views ·0 Reviews -

EIL Registered Manufacturers: Ensuring Quality and Reliability in Industrial Solutions

When it comes to large-scale industrial projects in sectors like oil & gas, petrochemicals, fertilizers, and refineries, quality and compliance are non-negotiable. One of the most trusted certifications in India for manufacturers is registration with Engineers India Limited (EIL). Being listed as EIL registered manufacturers is a mark of excellence, reliability, and adherence to stringent industry standards.

At Gas Processing, we take pride in being recognized among the trusted EIL registered manufacturers, delivering top-quality equipment and solutions that meet the highest levels of safety and performance.

What Does It Mean to Be an EIL Registered Manufacturer?

EIL, a leading engineering consultancy and EPC company in India, has a robust vendor registration process. Manufacturers who are registered with EIL undergo thorough technical evaluations, quality checks, and audits to ensure their products comply with industry norms.

By working with EIL registered manufacturers, clients can be assured of:

Compliance with international quality standards

Reliable performance in critical operations

Safety-tested and durable equipment

Hassle-free approval in EIL-supervised projects

Why Choose Gas Processing as Your EIL Registered Manufacturer?

At Gas Processing, we are committed to engineering excellence and customer satisfaction. Our status as EIL registered manufacturers ensures that every product we deliver meets rigorous quality requirements. From design to fabrication and testing, our processes align with EIL’s specifications.

We specialize in:

Process equipment for oil & gas industries

Pressure vessels and filter vessels

Heat exchangers and PSA systems

Biogas and renewable energy solutions

Our products are built with precision, keeping in mind the operational challenges of industries where downtime is not an option.

Benefits of Partnering with Gas Processing

Assured Quality & Certification – Every unit undergoes stringent testing before dispatch.

EIL Approval Advantage – Ensures smooth acceptance in EIL-monitored projects.

Customization – Tailor-made solutions as per client specifications.

Experience & Expertise – Years of serving industries with reliable engineering solutions.

Conclusion

Choosing an EIL registered manufacturer means choosing reliability, trust, and long-term value. At Gas Processing, we are proud to deliver world-class solutions that are not only compliant but also innovative and cost-effective.

If you are looking for a trusted partner in the field of industrial equipment manufacturing, Gas Processing is here to meet your needs with quality, efficiency, and commitment.

Visit us https://gasprocessing.in/processing-equipment/

EIL Registered Manufacturers: Ensuring Quality and Reliability in Industrial Solutions When it comes to large-scale industrial projects in sectors like oil & gas, petrochemicals, fertilizers, and refineries, quality and compliance are non-negotiable. One of the most trusted certifications in India for manufacturers is registration with Engineers India Limited (EIL). Being listed as EIL registered manufacturers is a mark of excellence, reliability, and adherence to stringent industry standards. At Gas Processing, we take pride in being recognized among the trusted EIL registered manufacturers, delivering top-quality equipment and solutions that meet the highest levels of safety and performance. What Does It Mean to Be an EIL Registered Manufacturer? EIL, a leading engineering consultancy and EPC company in India, has a robust vendor registration process. Manufacturers who are registered with EIL undergo thorough technical evaluations, quality checks, and audits to ensure their products comply with industry norms. By working with EIL registered manufacturers, clients can be assured of: ✅ Compliance with international quality standards ✅ Reliable performance in critical operations ✅ Safety-tested and durable equipment ✅ Hassle-free approval in EIL-supervised projects Why Choose Gas Processing as Your EIL Registered Manufacturer? At Gas Processing, we are committed to engineering excellence and customer satisfaction. Our status as EIL registered manufacturers ensures that every product we deliver meets rigorous quality requirements. From design to fabrication and testing, our processes align with EIL’s specifications. We specialize in: Process equipment for oil & gas industries Pressure vessels and filter vessels Heat exchangers and PSA systems Biogas and renewable energy solutions Our products are built with precision, keeping in mind the operational challenges of industries where downtime is not an option. Benefits of Partnering with Gas Processing Assured Quality & Certification – Every unit undergoes stringent testing before dispatch. EIL Approval Advantage – Ensures smooth acceptance in EIL-monitored projects. Customization – Tailor-made solutions as per client specifications. Experience & Expertise – Years of serving industries with reliable engineering solutions. Conclusion Choosing an EIL registered manufacturer means choosing reliability, trust, and long-term value. At Gas Processing, we are proud to deliver world-class solutions that are not only compliant but also innovative and cost-effective. If you are looking for a trusted partner in the field of industrial equipment manufacturing, Gas Processing is here to meet your needs with quality, efficiency, and commitment. Visit us https://gasprocessing.in/processing-equipment/0 Comments ·0 Shares ·212 Views ·0 Reviews -

Why U Stamp Pressure Vessels are Essential for Industrial Safety and Performance

When it comes to industrial equipment that handles high pressure, safety and compliance are non-negotiable. That’s where U Stamp Pressure Vessels come in — certified equipment that ensures maximum safety, reliability, and efficiency in demanding industrial environments.

At GasProcessing, we specialize in manufacturing and supplying U Stamp Pressure Vessels that meet stringent international standards, ensuring our clients get the highest quality solutions for their operations.

What is a U Stamp Pressure Vessel?

A U Stamp is a certification issued by the American Society of Mechanical Engineers (ASME) for pressure vessels. It signifies that the vessel has been designed and manufactured in compliance with the ASME Boiler and Pressure Vessel Code (BPVC), particularly Section VIII.

This stamp is globally recognized and essential for industries that deal with hazardous or high-pressure materials, such as oil & gas, chemical processing, power generation, and pharmaceuticals.

Why Choose U Stamp Pressure Vessels?

Here are the top benefits of using U Stamp-certified pressure vessels:

International Compliance

U Stamp vessels comply with global safety and quality standards, ensuring seamless exports and reduced regulatory issues.

Enhanced Safety

Certified vessels go through rigorous testing and inspection, making them safe for storing or transporting high-pressure gases and liquids.

Longevity and Durability

Manufactured using premium-grade materials and tested under extreme conditions, these vessels are built to last.

Improved Operational Efficiency

Precision engineering ensures optimal performance, reducing downtime and increasing productivity.

Insurance & Legal Requirements

Many industries require U Stamp vessels for insurance coverage and legal operation, making them a necessary investment.

Applications of U Stamp Pressure Vessels

At GasProcessing, our U Stamp Pressure Vessels are used in various industries:

Petrochemical Plants

Natural Gas Processing Units

Power Generation Plants

Water Treatment Facilities

Pharmaceutical Manufacturing

We design custom pressure vessels to match specific pressure ratings, temperature requirements, and media compatibility.

Why Choose GasProcessing?

With decades of experience in pressure equipment manufacturing, GasProcessing offers:

ASME U Stamp Certified Vessels

Custom Design & Fabrication

High-Quality Material Selection

On-Time Delivery

Compliance with Global Standards

We are committed to delivering pressure vessels that don’t just meet expectations — they exceed them.

Final Thoughts

In a world where operational safety and compliance are paramount, U Stamp Pressure Vessels offer unmatched reliability. Partnering with GasProcessing ensures your equipment is built to perform under pressure — literally.

Ready to upgrade to certified quality?

Contact GasProcessing today for customized U Stamp Pressure Vessels built to meet your industry’s demands.

Visit us http://gasprocessing.in/u-stamp-pressure-vessels-cyclic-design/

Why U Stamp Pressure Vessels are Essential for Industrial Safety and Performance When it comes to industrial equipment that handles high pressure, safety and compliance are non-negotiable. That’s where U Stamp Pressure Vessels come in — certified equipment that ensures maximum safety, reliability, and efficiency in demanding industrial environments. At GasProcessing, we specialize in manufacturing and supplying U Stamp Pressure Vessels that meet stringent international standards, ensuring our clients get the highest quality solutions for their operations. What is a U Stamp Pressure Vessel? A U Stamp is a certification issued by the American Society of Mechanical Engineers (ASME) for pressure vessels. It signifies that the vessel has been designed and manufactured in compliance with the ASME Boiler and Pressure Vessel Code (BPVC), particularly Section VIII. This stamp is globally recognized and essential for industries that deal with hazardous or high-pressure materials, such as oil & gas, chemical processing, power generation, and pharmaceuticals. Why Choose U Stamp Pressure Vessels? Here are the top benefits of using U Stamp-certified pressure vessels: International Compliance U Stamp vessels comply with global safety and quality standards, ensuring seamless exports and reduced regulatory issues. Enhanced Safety Certified vessels go through rigorous testing and inspection, making them safe for storing or transporting high-pressure gases and liquids. Longevity and Durability Manufactured using premium-grade materials and tested under extreme conditions, these vessels are built to last. Improved Operational Efficiency Precision engineering ensures optimal performance, reducing downtime and increasing productivity. Insurance & Legal Requirements Many industries require U Stamp vessels for insurance coverage and legal operation, making them a necessary investment. Applications of U Stamp Pressure Vessels At GasProcessing, our U Stamp Pressure Vessels are used in various industries: Petrochemical Plants Natural Gas Processing Units Power Generation Plants Water Treatment Facilities Pharmaceutical Manufacturing We design custom pressure vessels to match specific pressure ratings, temperature requirements, and media compatibility. Why Choose GasProcessing? With decades of experience in pressure equipment manufacturing, GasProcessing offers: ✅ ASME U Stamp Certified Vessels ✅ Custom Design & Fabrication ✅ High-Quality Material Selection ✅ On-Time Delivery ✅ Compliance with Global Standards We are committed to delivering pressure vessels that don’t just meet expectations — they exceed them. Final Thoughts In a world where operational safety and compliance are paramount, U Stamp Pressure Vessels offer unmatched reliability. Partnering with GasProcessing ensures your equipment is built to perform under pressure — literally. Ready to upgrade to certified quality? 📞 Contact GasProcessing today for customized U Stamp Pressure Vessels built to meet your industry’s demands. Visit us http://gasprocessing.in/u-stamp-pressure-vessels-cyclic-design/0 Comments ·0 Shares ·180 Views ·0 Reviews -

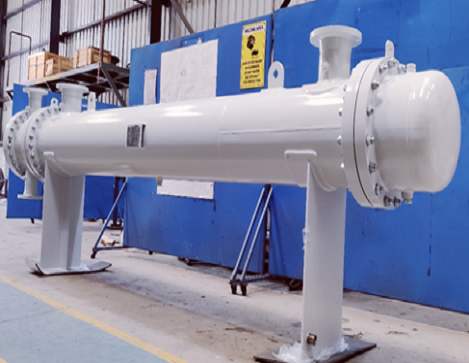

Enhancing Efficiency with Non-Ferrous Heat Exchangers – A Smart Choice by Gas Processing

In industries where corrosion resistance, thermal efficiency, and longevity are critical, Non-Ferrous Heat Exchangers have become the preferred solution. Whether it's chemical processing, power generation, or HVAC systems, choosing the right heat exchanger material can make a massive difference in performance and maintenance costs.

At Gas Processing, we specialize in advanced, custom-engineered non-ferrous heat exchangers that offer superior performance and reliability across a wide range of industrial applications.

What Are Non-Ferrous Heat Exchangers?

Non-ferrous heat exchangers are built using metals that do not contain significant amounts of iron. Common non-ferrous materials include:

Copper

Aluminum

Brass

Titanium

Nickel Alloys

These materials are chosen for their excellent corrosion resistance, lightweight properties, and superior thermal conductivity compared to ferrous metals like steel.

Key Benefits of Non-Ferrous Heat Exchangers

1. Corrosion Resistance

In industries dealing with aggressive fluids, saltwater, or acidic environments, corrosion is a major challenge. Non-ferrous metals like copper-nickel and titanium resist corrosion far better than carbon steel, significantly extending the life of the heat exchanger.

2. Superior Thermal Conductivity

Materials like copper and aluminum are excellent conductors of heat, allowing faster and more efficient heat transfer. This leads to better energy efficiency and smaller unit sizes.

3. Lightweight and Compact

Non-ferrous heat exchangers are often lighter, making them easier to install and maintain. Their compact design also allows for greater space savings in tight installations.

4. Low Maintenance Requirements

Because of their resistance to scale, corrosion, and fouling, non-ferrous exchangers require less frequent cleaning and inspection—reducing operational downtime.

Applications of Non-Ferrous Heat Exchangers

Non-ferrous heat exchangers are used in various industries, including:

Chemical & Petrochemical Plants

Marine and Offshore Applications

Power Generation

Pharmaceuticals

Food & Beverage Processing

HVAC & Refrigeration Systems

Their versatility and robustness make them suitable for both high-pressure and high-temperature environments.

Why Choose Gas Processing?

At Gas Processing, we combine decades of engineering expertise with state-of-the-art manufacturing technology to deliver non-ferrous heat exchangers that are:

Custom-designed to meet your specific process needs

Manufactured to international standards (ASME, TEMA, ISO)

Available in various configurations: shell & tube, plate, finned, and more

Rigorously tested for quality, pressure, and performance

Our team works closely with clients from concept to commissioning, ensuring a seamless integration into your process system.

Conclusion

Whether you're upgrading an existing system or designing a new plant, choosing a non-ferrous heat exchanger can dramatically improve your system's durability, efficiency, and reliability. With Gas Processing, you're not just buying a product—you're investing in performance, precision, and peace of mind.

Ready to elevate your heat transfer solutions? Contact Gas Processing today to discuss your non-ferrous heat exchanger requirements.

Visit us https://gasprocessing.in/processing-equipment/

Enhancing Efficiency with Non-Ferrous Heat Exchangers – A Smart Choice by Gas Processing In industries where corrosion resistance, thermal efficiency, and longevity are critical, Non-Ferrous Heat Exchangers have become the preferred solution. Whether it's chemical processing, power generation, or HVAC systems, choosing the right heat exchanger material can make a massive difference in performance and maintenance costs. At Gas Processing, we specialize in advanced, custom-engineered non-ferrous heat exchangers that offer superior performance and reliability across a wide range of industrial applications. What Are Non-Ferrous Heat Exchangers? Non-ferrous heat exchangers are built using metals that do not contain significant amounts of iron. Common non-ferrous materials include: Copper Aluminum Brass Titanium Nickel Alloys These materials are chosen for their excellent corrosion resistance, lightweight properties, and superior thermal conductivity compared to ferrous metals like steel. Key Benefits of Non-Ferrous Heat Exchangers 1. Corrosion Resistance In industries dealing with aggressive fluids, saltwater, or acidic environments, corrosion is a major challenge. Non-ferrous metals like copper-nickel and titanium resist corrosion far better than carbon steel, significantly extending the life of the heat exchanger. 2. Superior Thermal Conductivity Materials like copper and aluminum are excellent conductors of heat, allowing faster and more efficient heat transfer. This leads to better energy efficiency and smaller unit sizes. 3. Lightweight and Compact Non-ferrous heat exchangers are often lighter, making them easier to install and maintain. Their compact design also allows for greater space savings in tight installations. 4. Low Maintenance Requirements Because of their resistance to scale, corrosion, and fouling, non-ferrous exchangers require less frequent cleaning and inspection—reducing operational downtime. Applications of Non-Ferrous Heat Exchangers Non-ferrous heat exchangers are used in various industries, including: Chemical & Petrochemical Plants Marine and Offshore Applications Power Generation Pharmaceuticals Food & Beverage Processing HVAC & Refrigeration Systems Their versatility and robustness make them suitable for both high-pressure and high-temperature environments. Why Choose Gas Processing? At Gas Processing, we combine decades of engineering expertise with state-of-the-art manufacturing technology to deliver non-ferrous heat exchangers that are: Custom-designed to meet your specific process needs Manufactured to international standards (ASME, TEMA, ISO) Available in various configurations: shell & tube, plate, finned, and more Rigorously tested for quality, pressure, and performance Our team works closely with clients from concept to commissioning, ensuring a seamless integration into your process system. Conclusion Whether you're upgrading an existing system or designing a new plant, choosing a non-ferrous heat exchanger can dramatically improve your system's durability, efficiency, and reliability. With Gas Processing, you're not just buying a product—you're investing in performance, precision, and peace of mind. 📞 Ready to elevate your heat transfer solutions? Contact Gas Processing today to discuss your non-ferrous heat exchanger requirements. Visit us https://gasprocessing.in/processing-equipment/0 Comments ·0 Shares ·304 Views ·0 Reviews

More Stories