In today's fast-paced and ever-changing business environment, optimizing your supply chain is crucial to staying competitive and meeting customer demands. One innovative solution that can help streamline your operations and improve efficiency is a dimensioning system. By implementing this cutting-edge technology, you can accurately measure and weigh packages, pallets, and other shipments, allowing you to better manage inventory, reduce shipping costs, and enhance overall productivity.

What is a Dimensioning System?

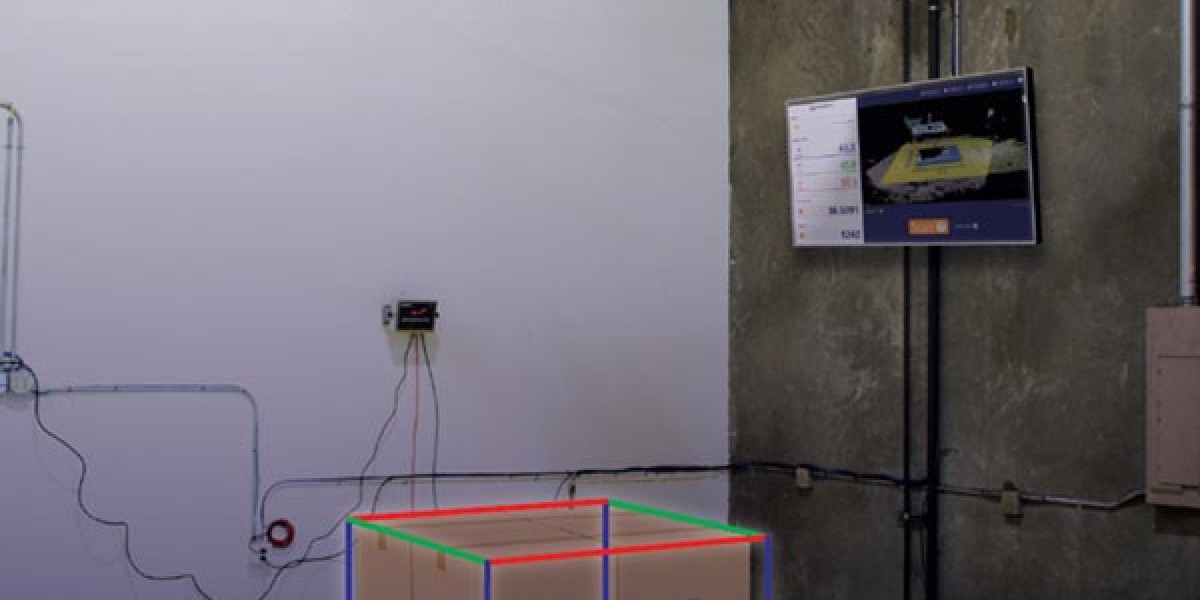

A dimensioning system is a sophisticated piece of equipment that utilizes advanced technology such as lasers, cameras, and sensors to accurately measure the dimensions and weight of various objects. This data is then used to automate processes such as sorting, labeling, and tracking shipments, making the entire supply chain more efficient and cost-effective. With a dimensioning system in place, you can eliminate manual measurement errors, reduce labor costs, and improve accuracy across your operations.

How Does a Dimensioning System Work?

The process of dimensioning begins with the placement of an object on the system's platform. The lasers and cameras then capture detailed measurements of the object's length, width, height, and weight in a matter of seconds. This data is instantly processed and integrated into your existing warehouse management system, allowing you to make informed decisions in real-time. By automating the dimensioning process, you can save valuable time and resources while improving the overall accuracy of your supply chain operations.

Benefits of Implementing a Dimensioning System

There are numerous benefits to incorporating a dimensioning system into your supply chain operations. Some of the key advantages include:

Increased Efficiency: By automating the dimensioning process, you can streamline operations and reduce the time it takes to measure and weigh shipments.

Cost Savings: With accurate measurements, you can avoid costly shipping errors and eliminate unnecessary charges from carriers due to incorrect dimensions.

Improved Accuracy: By eliminating manual measurement errors, you can ensure that shipments are accurately labeled and processed, reducing the risk of delays or inaccuracies.

Enhanced Visibility: A dimensioning system provides real-time data on shipments, allowing you to track and monitor inventory levels more effectively.

Better Customer Service: By optimizing your supply chain with a dimensioning system, you can improve order accuracy and fulfillment, leading to increased customer satisfaction.

Is a Dimensioning System Right for Your Business?

If you are looking to optimize your supply chain operations, improve efficiency, and reduce costs, implementing a dimensioning system may be the right choice for your business. Whether you are a small e-commerce retailer or a large distribution center, this innovative technology can help you stay ahead of the competition and meet the demands of today's fast-paced marketplace. With its numerous benefits and tangible results, a dimensioning system can transform the way you manage your supply chain and drive success for your business.

In conclusion, optimizing your supply chain with an innovative dimensioning system is a smart investment that can deliver significant benefits to your business. By automating the measurement and weighing process, you can improve efficiency, reduce costs, and enhance overall accuracy in your operations. Whether you are looking to streamline your warehouse operations or improve order fulfillment, a dimensioning system can help you achieve your goals and stay ahead of the competition.