Polyvinyl alcohol (PVA) is a synthetic polymer widely used across various industries, including textiles, paper, adhesives, and biomedical fields. PVA is unique due to its water-solubility, biodegradability, and non-toxic nature, making it an attractive material for a range of applications. When modified, PVA can exhibit enhanced properties, making it more versatile and suitable for more specialized uses. Modified polyvinyl alcohol (MPVA) refers to PVA that has been altered chemically, physically, or through blending with other materials to improve specific properties such as its mechanical strength, thermal stability, and resistance to water.

Chemical Modification of Polyvinyl Alcohol

Chemical modifications of PVA generally involve altering its molecular structure by introducing functional groups or crosslinking agents. These modifications can significantly influence the physical and chemical properties of PVA.

- Crosslinking: One of the most common modifications involves crosslinking, which creates a network of interconnected polymer chains. This enhances the mechanical strength, stability, and resistance to water of the polymer. Crosslinked PVA has improved properties such as higher tensile strength and better dimensional stability, making it suitable for use in coatings, films, and hydrogels. Crosslinking can be achieved through physical methods, such as irradiation, or chemical methods using agents like borax or glutaraldehyde.

- Grafting: Grafting involves attaching additional polymer chains onto the PVA backbone. This can be done by chemical reactions that allow the incorporation of other monomers or functional groups onto PVA. This modification can improve the polymer's thermal stability, chemical resistance, and hydrophobicity. Grafted PVA has applications in areas where enhanced chemical durability is required, such as in coatings for industrial use.

- Acetylation: Acetylation is another common chemical modification, where acetic acid or its derivatives are introduced into the PVA structure. Acetylated PVA has reduced water solubility, making it more suitable for applications where PVA needs to maintain stability in wet or humid conditions. This modification is particularly useful in the production of non-woven fabrics and other materials that require improved moisture resistance.

- Sulfation and Phosphorylation: Introducing sulfate or phosphate groups into the PVA chain can improve its water retention, film-forming properties, and biocompatibility. These modifications are beneficial for biomedical applications, such as drug delivery systems or wound dressings, as they improve the interaction of the polymer with biological tissues and fluids.

Physical Modification of Polyvinyl Alcohol

In addition to chemical modifications, PVA can also be physically modified. Physical modification generally involves altering the polymer's morphology or structure without changing its chemical composition.

- Blending with Other Polymers: PVA is often blended with other polymers, such as polyethylene glycol (PEG), polylactic acid (PLA), or polyvinyl pyrrolidone (PVP). These blends can result in materials with improved properties such as increased flexibility, enhanced biodegradability, and improved processability. These blends are often used in the packaging industry or in the creation of water-soluble films.

- Nanocomposite Formation: PVA can be combined with nanoparticles, such as clay, silica, or carbon-based materials, to form nanocomposites. These materials exhibit superior mechanical, thermal, and barrier properties compared to unmodified PVA. Nanocomposites are gaining popularity in industries such as food packaging, where the material must have excellent barrier properties against gases, moisture, and UV light.

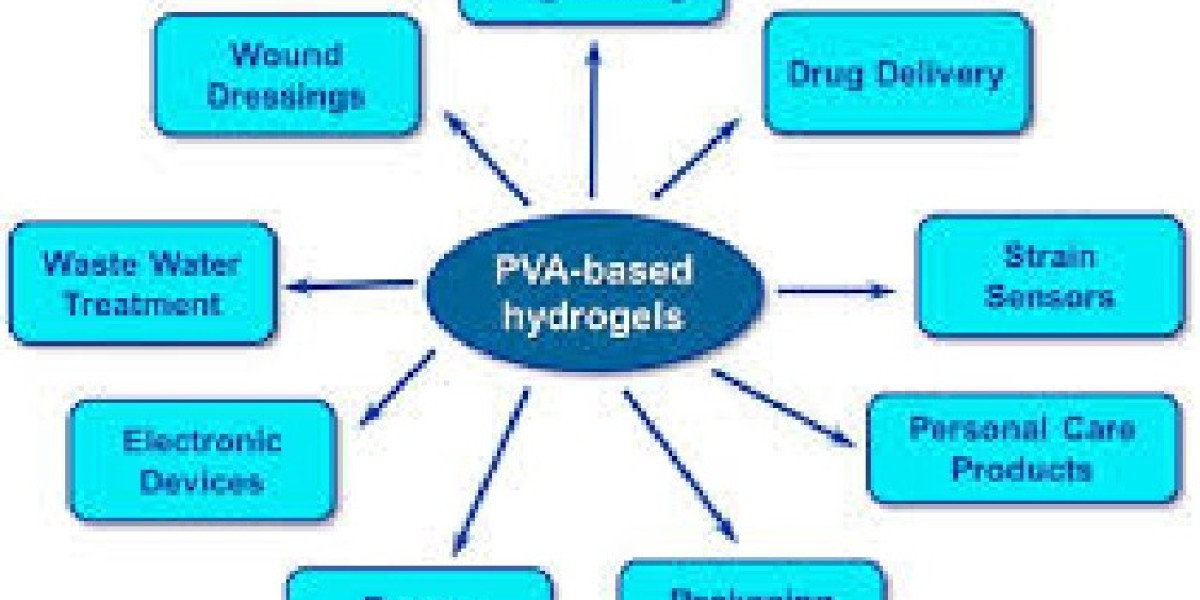

Applications of Modified Polyvinyl Alcohol

Modified PVA has a broad range of applications due to its adaptable properties. Some key areas where MPVA is used include:

- Biomedical Applications: Modified PVA is extensively used in the biomedical field for controlled drug release systems, wound dressings, and tissue engineering. Its biocompatibility and ability to form hydrogels make it suitable for drug delivery systems, where it can release therapeutics in a controlled manner over time.

- Water-Soluble Films: Modified PVA is frequently used in water-soluble films for packaging, especially in single-use applications like laundry pods or agricultural mulch films. These films dissolve in water, leaving no residue and reducing plastic waste.

- Adhesives and Coatings: MPVA is used as an adhesive in a variety of applications, from packaging to construction. The modification improves the adhesive properties, allowing it to bond effectively with different materials. It is also used in coatings to enhance film-forming capabilities and to improve water resistance.

- Textiles and Paper: Modified PVA is utilized in the textile and paper industries to enhance fiber bonding, improve dye uptake, and impart desirable qualities such as water resistance. It is also used in textile finishes that enhance fabric durability.

Conclusion

Modified polyvinyl alcohol is a versatile and highly adaptable material that offers significant advantages across many fields, from packaging to healthcare. By altering its chemical or physical properties, PVA can be tailored to meet the demands of specific applications, whether it be improved mechanical strength, water resistance, or biocompatibility. The ongoing development of MPVA continues to open new possibilities in various industries, making it a key material in modern technology.