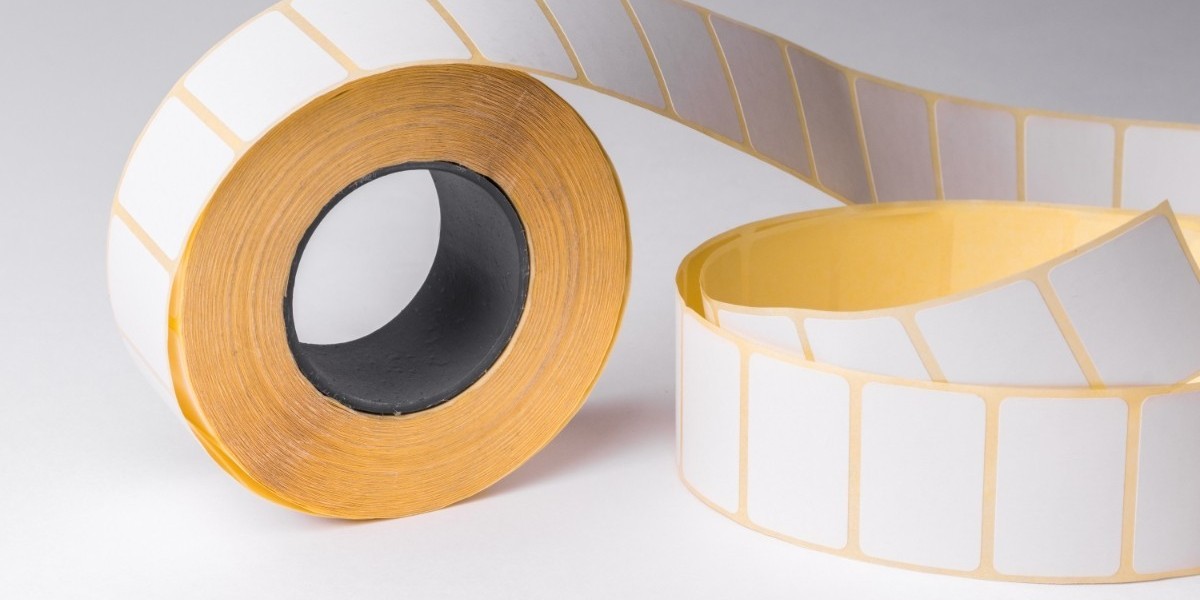

In today’s fast-paced industries, high-quality, durable labeling solutions are essential for effective inventory management, shipping, and product identification. Among the various labeling options available, thermal transfer labels stand out as the preferred choice for businesses looking for long-lasting prints. These labels provide superior print durability, resistance to environmental factors, and versatility across industries. In this article, we will explore the advantages of thermal transfer labels and why they are the best option for long-term applications.

Understanding Thermal Transfer Labels

Thermal transfer labels are created using a process that involves heat and a specialized ribbon. The printer’s thermal printhead applies heat to the ribbon, transferring ink onto the label material. This results in crisp, high-quality prints that resist smudging, fading, and environmental wear. Unlike direct thermal labels, which rely on heat-sensitive paper and tend to degrade over time, thermal transfer labels are designed to maintain their integrity for extended periods.

Advantages of Thermal Transfer Labels

Superior Print Durability

One of the main reasons thermal transfer labels are highly preferred is their exceptional print longevity. These labels are designed to withstand exposure to moisture, chemicals, heat, and UV light, making them an excellent choice for long-term applications. Unlike direct thermal prints, which fade over time, thermal transfer labels retain their clarity for years, ensuring reliable tracking and identification.

Resistance to Environmental Factors

Thermal transfer labels are ideal for harsh environments where labels must endure extreme temperatures, humidity, and rough handling. Whether used in outdoor settings, industrial warehouses, or healthcare facilities, these labels remain intact and legible. The ink from the ribbon adheres firmly to the label material, providing resistance to abrasion and smudging, which is crucial for barcode scanning and inventory management.

Versatile Material Options

Thermal transfer labels come in a wide range of materials, allowing businesses to choose the best option for their specific needs. Common materials include:

Paper Labels – Suitable for short-term use in controlled environments.

Polypropylene Labels – Resistant to moisture and chemicals, ideal for industrial use.

Polyester Labels – Highly durable and suited for extreme conditions such as outdoor exposure.

Vinyl Labels – Flexible and tear-resistant, making them ideal for curved surfaces and rugged applications.

The ability to select the right material ensures that businesses can optimize label performance based on their industry requirements.

Industries That Benefit from Thermal Transfer Labels

Many industries rely on thermal transfer labels for their durability and high-quality print output. Some of the key sectors that benefit from these labels include:

Retail & E-commerce

Retailers and e-commerce businesses use thermal transfer labels for product labeling, inventory tracking, and shipping. The long-lasting prints ensure barcodes remain scannable throughout the supply chain, reducing errors in order fulfillment.

Manufacturing & Warehousing

Manufacturers and warehouse operators require labels that can withstand extreme conditions, including exposure to chemicals, moisture, and high temperatures. Thermal transfer labels provide a reliable solution for equipment labeling, asset tracking, and logistics management.

Healthcare & Pharmaceuticals

In the healthcare industry, accuracy and durability are critical. Thermal transfer labels are used for patient wristbands, specimen identification, and pharmaceutical labeling. Their resistance to smudging and fading ensures vital information remains legible.

Food & Beverage

Food manufacturers and distributors rely on thermal transfer labels to comply with regulatory labeling requirements. These labels withstand refrigeration, freezing, and exposure to oils, ensuring that product information and expiration dates remain clear.

Choosing the Right Ribbon for Thermal Transfer Labels

Selecting the appropriate ribbon type is crucial to achieving optimal print quality and durability. There are three main types of thermal transfer ribbons:

Wax Ribbons – Best for general-purpose applications on paper labels. They provide good print quality but are less resistant to smudging.

Wax-Resin Ribbons – Offer enhanced durability and work well on both paper and synthetic materials. They provide moderate resistance to moisture and abrasion.

Resin Ribbons – The most durable option, ideal for printing on polyester and vinyl labels. These ribbons are resistant to chemicals, heat, and extreme environments.

Matching the ribbon type to the label material ensures long-lasting prints and optimal performance in specific applications.

Comparing Thermal Transfer Labels to Other Labeling Methods

When deciding on the best labeling solution, it’s important to compare thermal transfer labels with other popular options.

Thermal Transfer vs. Direct Thermal Labels

Direct Thermal Labels use heat-sensitive paper that darkens when exposed to heat. While they are cost-effective and suitable for short-term applications, they fade over time and are prone to damage from heat and light.

Thermal Transfer Labels use a ribbon to create more durable prints. They are ideal for long-term applications that require resistance to harsh conditions.

Thermal Transfer vs. Laser & Inkjet Labels

Laser and Inkjet Labels require expensive ink or toner and may not provide the same level of durability.

Thermal Transfer Labels produce long-lasting, smudge-resistant prints at a lower operational cost.

Cost Efficiency and Sustainability

Although thermal transfer labels may have a slightly higher initial investment compared to direct thermal labels, their long-term benefits outweigh the costs. Their durability reduces the need for frequent replacements, saving businesses money on reprinting and label waste.

Additionally, many thermal transfer ribbons and label materials are now available in eco-friendly options, supporting sustainability efforts in various industries. Recycling programs and biodegradable label materials further enhance their environmental appeal.

Conclusion

For businesses that require durable, high-quality labeling solutions, thermal transfer labels are the best choice. Their superior print longevity, resistance to environmental factors, and versatility across industries make them a reliable solution for long-term applications. Whether used in retail, healthcare, or manufacturing, these labels ensure that critical information remains intact for years. When paired with the right ribbon and label material, thermal transfer labels provide unmatched performance and cost efficiency. If you’re looking for a labeling solution that withstands time and harsh conditions, consider upgrading to thermal transfer labels for your 4x6 labels and other business needs.