Precision in Every Curve: How CNC Bending is Revolutionizing Metal Fabrication

In the ever-evolving world of metal fabrication, precision and efficiency are no longer optional—they’re essential. Modern manufacturing demands tight tolerances, consistent results, and faster turnaround times. This is where CNC Bending Services have emerged as a game-changer, redefining how industries approach metal shaping and forming.

What Is CNC Bending?

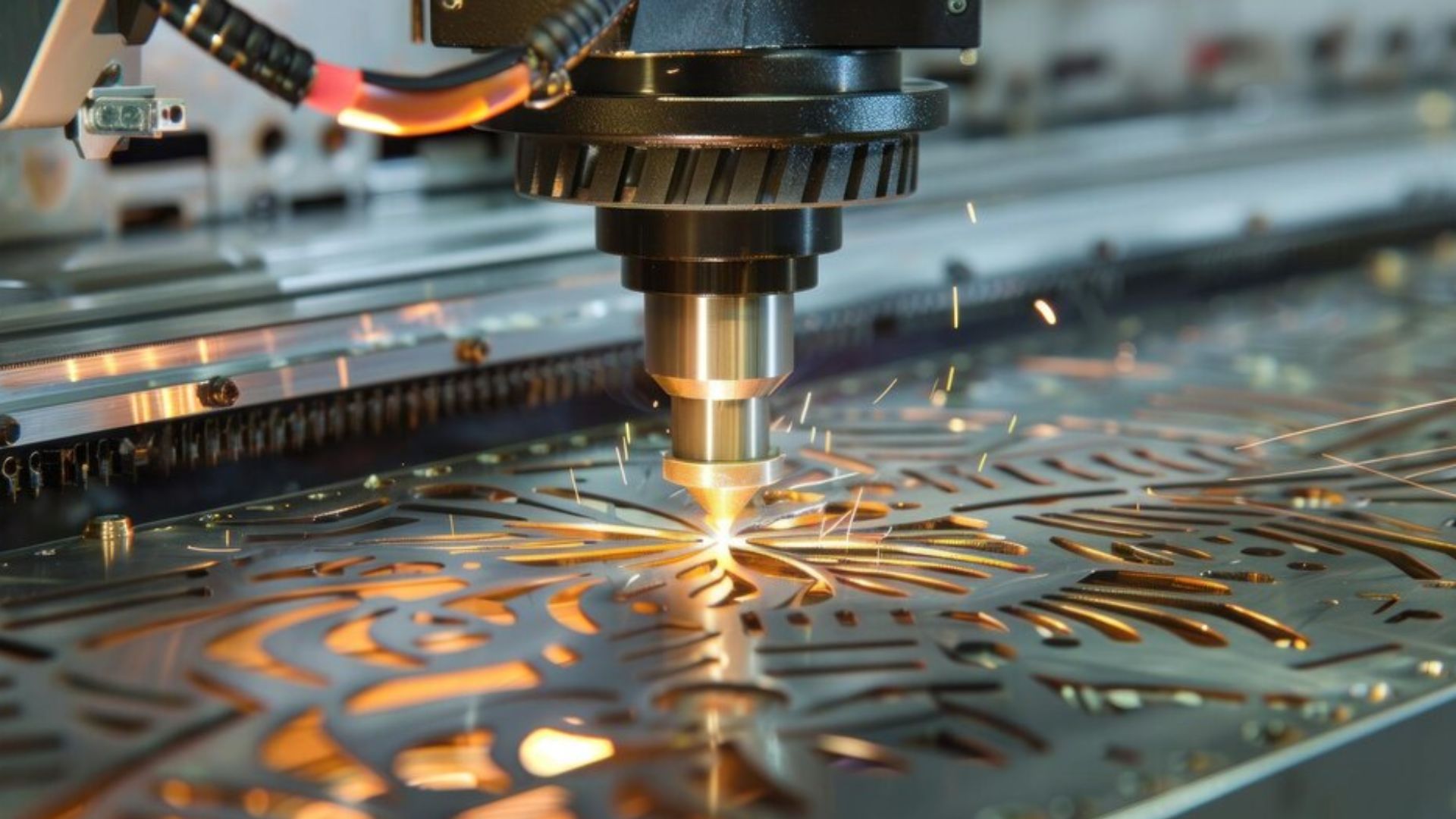

CNC (Computer Numerical Control) Bending is a process that uses computer-controlled machines to bend sheet metal with extreme precision. Unlike manual bending, CNC technology allows for repeatable, error-free production, ensuring each part matches exact specifications. This technology is commonly used for materials like steel, aluminum, and stainless steel, producing components for automotive, construction, aerospace, and industrial applications.

The Power of Precision in Metal CNC Bending

Every angle, curve, and fold in a metal part affects the product’s overall quality and performance. Metal CNC Bending ensures unmatched accuracy by using advanced software to control the bending angles, pressure, and sequence. This reduces human error and material waste while maintaining consistent quality throughout production.

For manufacturers, this precision translates to better fitting parts, reduced rework, and improved product durability—all while saving time and costs.

Key Advantages of CNC Bending Services

High Accuracy and Consistency

CNC bending machines follow pre-programmed commands to deliver consistent results, no matter how complex the design.

Efficiency and Speed

Automated setups and quick tooling adjustments make CNC bending ideal for both small and large-volume production.

Design Flexibility

From simple angles to intricate shapes, CNC bending can handle diverse designs, allowing engineers more creative freedom.

Cost-Effective Production

With reduced labor requirements and minimal waste, CNC bending is one of the most economical methods for precision metal fabrication.

Enhanced Durability

The precise bending process ensures uniform stress distribution across the metal, improving the strength and longevity of components.

Applications of Metal CNC Bending

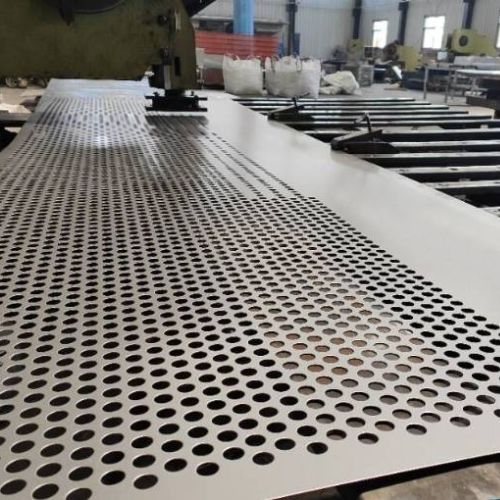

CNC bending plays a crucial role in producing components such as brackets, enclosures, frames, and panels used across various industries. Whether it’s the automotive sector needing structural parts or the construction industry requiring custom-fit panels, CNC bending provides the adaptability and precision modern projects demand.

Why Choose Raamps Industries for CNC Bending Services?

Raamps Industries stands at the forefront of CNC Bending Services, combining advanced technology with years of industry expertise. The company delivers tailored Metal CNC Bending solutions that meet strict client specifications while maintaining exceptional quality and turnaround speed. From prototype development to full-scale production, Raamps Industries ensures every curve, edge, and angle meets perfection.

Conclusion

The future of metal fabrication lies in precision, speed, and efficiency—and CNC Bending Services perfectly embody these principles. As industries continue to innovate and demand higher standards, Metal CNC Bending will remain a cornerstone of modern manufacturing. With leaders like Raamps Industries, businesses can trust that every curve is crafted with accuracy, durability, and excellence in mind.

https://www.raampsindustries.com/services/cnc-bending/

Precision in Every Curve: How CNC Bending is Revolutionizing Metal Fabrication

In the ever-evolving world of metal fabrication, precision and efficiency are no longer optional—they’re essential. Modern manufacturing demands tight tolerances, consistent results, and faster turnaround times. This is where CNC Bending Services have emerged as a game-changer, redefining how industries approach metal shaping and forming.

What Is CNC Bending?

CNC (Computer Numerical Control) Bending is a process that uses computer-controlled machines to bend sheet metal with extreme precision. Unlike manual bending, CNC technology allows for repeatable, error-free production, ensuring each part matches exact specifications. This technology is commonly used for materials like steel, aluminum, and stainless steel, producing components for automotive, construction, aerospace, and industrial applications.

The Power of Precision in Metal CNC Bending

Every angle, curve, and fold in a metal part affects the product’s overall quality and performance. Metal CNC Bending ensures unmatched accuracy by using advanced software to control the bending angles, pressure, and sequence. This reduces human error and material waste while maintaining consistent quality throughout production.

For manufacturers, this precision translates to better fitting parts, reduced rework, and improved product durability—all while saving time and costs.

Key Advantages of CNC Bending Services

High Accuracy and Consistency

CNC bending machines follow pre-programmed commands to deliver consistent results, no matter how complex the design.

Efficiency and Speed

Automated setups and quick tooling adjustments make CNC bending ideal for both small and large-volume production.

Design Flexibility

From simple angles to intricate shapes, CNC bending can handle diverse designs, allowing engineers more creative freedom.

Cost-Effective Production

With reduced labor requirements and minimal waste, CNC bending is one of the most economical methods for precision metal fabrication.

Enhanced Durability

The precise bending process ensures uniform stress distribution across the metal, improving the strength and longevity of components.

Applications of Metal CNC Bending

CNC bending plays a crucial role in producing components such as brackets, enclosures, frames, and panels used across various industries. Whether it’s the automotive sector needing structural parts or the construction industry requiring custom-fit panels, CNC bending provides the adaptability and precision modern projects demand.

Why Choose Raamps Industries for CNC Bending Services?

Raamps Industries stands at the forefront of CNC Bending Services, combining advanced technology with years of industry expertise. The company delivers tailored Metal CNC Bending solutions that meet strict client specifications while maintaining exceptional quality and turnaround speed. From prototype development to full-scale production, Raamps Industries ensures every curve, edge, and angle meets perfection.

Conclusion

The future of metal fabrication lies in precision, speed, and efficiency—and CNC Bending Services perfectly embody these principles. As industries continue to innovate and demand higher standards, Metal CNC Bending will remain a cornerstone of modern manufacturing. With leaders like Raamps Industries, businesses can trust that every curve is crafted with accuracy, durability, and excellence in mind.

https://www.raampsindustries.com/services/cnc-bending/