Precision Engineering with CNC Punching Services by Raamps Industries

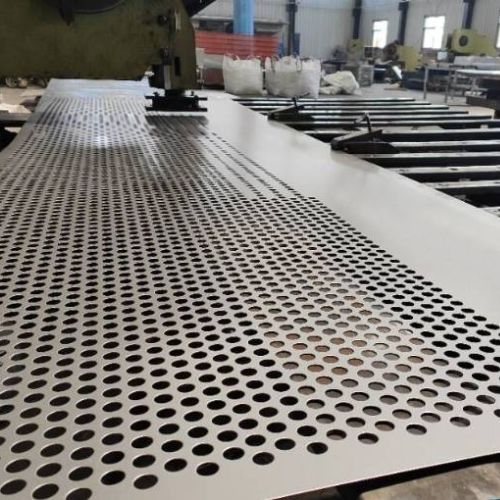

In today’s fast-paced manufacturing world, precision, speed, and efficiency are essential. When it comes to metal fabrication, CNC Punching Services play a vital role in delivering accurate results at scale. At Raamps Industries, we specialize in Metal CNC Punching, helping businesses achieve flawless components for industries ranging from automotive and electronics to construction and custom fabrication.

What is CNC Punching?

CNC Punching is a modern sheet metal fabrication process that uses computer-controlled machines to punch holes, shapes, or patterns into metal sheets. By combining precision with automation, CNC Punching ensures consistent results and high productivity.

This process is particularly useful for:

Creating ventilation patterns

Punching slots, louvers, or perforations

Shaping complex metal parts with repeat accuracy

Advantages of Metal CNC Punching

Choosing Metal CNC Punching offers several benefits for manufacturers and clients alike:

High Precision – Computer numerical control guarantees exact measurements and tolerances.

Efficiency – Large batches can be produced quickly, saving both time and cost.

Design Flexibility – Complex shapes and patterns can be created without compromising accuracy.

Cost-Effective – Less material waste and reduced manual labor lower overall production expenses.

Consistency – Every piece comes out identical, ensuring quality control in mass production.

Why Choose Raamps Industries for CNC Punching Services?

At Raamps Industries, we combine advanced CNC punching technology with years of expertise in metal fabrication. Our team ensures that every project meets industry standards and client expectations. Whether it’s a small custom order or a large-scale production run, our CNC Punching Services are tailored to meet your specific requirements.

We work with a variety of metals, including stainless steel, aluminum, and mild steel, ensuring durability and strength in every punched product.

Applications of CNC Punching

Automotive parts

Electrical enclosures

Architectural designs

HVAC components

Custom metal fabrication

Conclusion

In the competitive world of manufacturing, precision and efficiency are the keys to success. With CNC Punching Services from Raamps Industries, businesses gain access to advanced technology, reliable quality, and cost-effective solutions. Whether you need simple perforations or complex designs, our Metal CNC Punching expertise ensures that your projects are delivered with excellence every time.

Visit us -https://www.raampsindustries.com/services/cnc-punching/

In today’s fast-paced manufacturing world, precision, speed, and efficiency are essential. When it comes to metal fabrication, CNC Punching Services play a vital role in delivering accurate results at scale. At Raamps Industries, we specialize in Metal CNC Punching, helping businesses achieve flawless components for industries ranging from automotive and electronics to construction and custom fabrication.

What is CNC Punching?

CNC Punching is a modern sheet metal fabrication process that uses computer-controlled machines to punch holes, shapes, or patterns into metal sheets. By combining precision with automation, CNC Punching ensures consistent results and high productivity.

This process is particularly useful for:

Creating ventilation patterns

Punching slots, louvers, or perforations

Shaping complex metal parts with repeat accuracy

Advantages of Metal CNC Punching

Choosing Metal CNC Punching offers several benefits for manufacturers and clients alike:

High Precision – Computer numerical control guarantees exact measurements and tolerances.

Efficiency – Large batches can be produced quickly, saving both time and cost.

Design Flexibility – Complex shapes and patterns can be created without compromising accuracy.

Cost-Effective – Less material waste and reduced manual labor lower overall production expenses.

Consistency – Every piece comes out identical, ensuring quality control in mass production.

Why Choose Raamps Industries for CNC Punching Services?

At Raamps Industries, we combine advanced CNC punching technology with years of expertise in metal fabrication. Our team ensures that every project meets industry standards and client expectations. Whether it’s a small custom order or a large-scale production run, our CNC Punching Services are tailored to meet your specific requirements.

We work with a variety of metals, including stainless steel, aluminum, and mild steel, ensuring durability and strength in every punched product.

Applications of CNC Punching

Automotive parts

Electrical enclosures

Architectural designs

HVAC components

Custom metal fabrication

Conclusion

In the competitive world of manufacturing, precision and efficiency are the keys to success. With CNC Punching Services from Raamps Industries, businesses gain access to advanced technology, reliable quality, and cost-effective solutions. Whether you need simple perforations or complex designs, our Metal CNC Punching expertise ensures that your projects are delivered with excellence every time.

Visit us -https://www.raampsindustries.com/services/cnc-punching/

Precision Engineering with CNC Punching Services by Raamps Industries

In today’s fast-paced manufacturing world, precision, speed, and efficiency are essential. When it comes to metal fabrication, CNC Punching Services play a vital role in delivering accurate results at scale. At Raamps Industries, we specialize in Metal CNC Punching, helping businesses achieve flawless components for industries ranging from automotive and electronics to construction and custom fabrication.

What is CNC Punching?

CNC Punching is a modern sheet metal fabrication process that uses computer-controlled machines to punch holes, shapes, or patterns into metal sheets. By combining precision with automation, CNC Punching ensures consistent results and high productivity.

This process is particularly useful for:

Creating ventilation patterns

Punching slots, louvers, or perforations

Shaping complex metal parts with repeat accuracy

Advantages of Metal CNC Punching

Choosing Metal CNC Punching offers several benefits for manufacturers and clients alike:

High Precision – Computer numerical control guarantees exact measurements and tolerances.

Efficiency – Large batches can be produced quickly, saving both time and cost.

Design Flexibility – Complex shapes and patterns can be created without compromising accuracy.

Cost-Effective – Less material waste and reduced manual labor lower overall production expenses.

Consistency – Every piece comes out identical, ensuring quality control in mass production.

Why Choose Raamps Industries for CNC Punching Services?

At Raamps Industries, we combine advanced CNC punching technology with years of expertise in metal fabrication. Our team ensures that every project meets industry standards and client expectations. Whether it’s a small custom order or a large-scale production run, our CNC Punching Services are tailored to meet your specific requirements.

We work with a variety of metals, including stainless steel, aluminum, and mild steel, ensuring durability and strength in every punched product.

Applications of CNC Punching

Automotive parts

Electrical enclosures

Architectural designs

HVAC components

Custom metal fabrication

Conclusion

In the competitive world of manufacturing, precision and efficiency are the keys to success. With CNC Punching Services from Raamps Industries, businesses gain access to advanced technology, reliable quality, and cost-effective solutions. Whether you need simple perforations or complex designs, our Metal CNC Punching expertise ensures that your projects are delivered with excellence every time.

Visit us -https://www.raampsindustries.com/services/cnc-punching/

0 Reacties

·0 aandelen

·8 Views

·0 voorbeeld